- Overview of Glass Cutting Techniques and Industry Trends

- Technical Advantages in Modern Glass Cutting

- Comparative Analysis of Leading Glass Cutting Manufacturers

- Custom Solutions for Diverse Industrial Needs

- Material-Specific Cutting: Toughened vs. Float Glass

- Case Studies: Real-World Applications

- Future Innovations in Glass Cutting Patterns

(glass cutting patterns)

Understanding Glass Cutting Patterns and Industry Dynamics

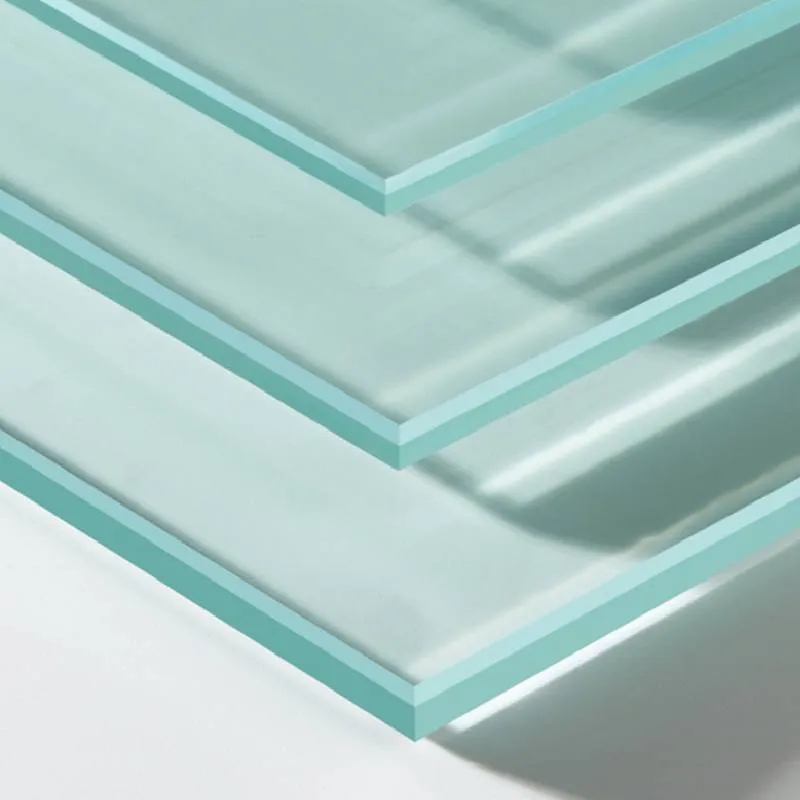

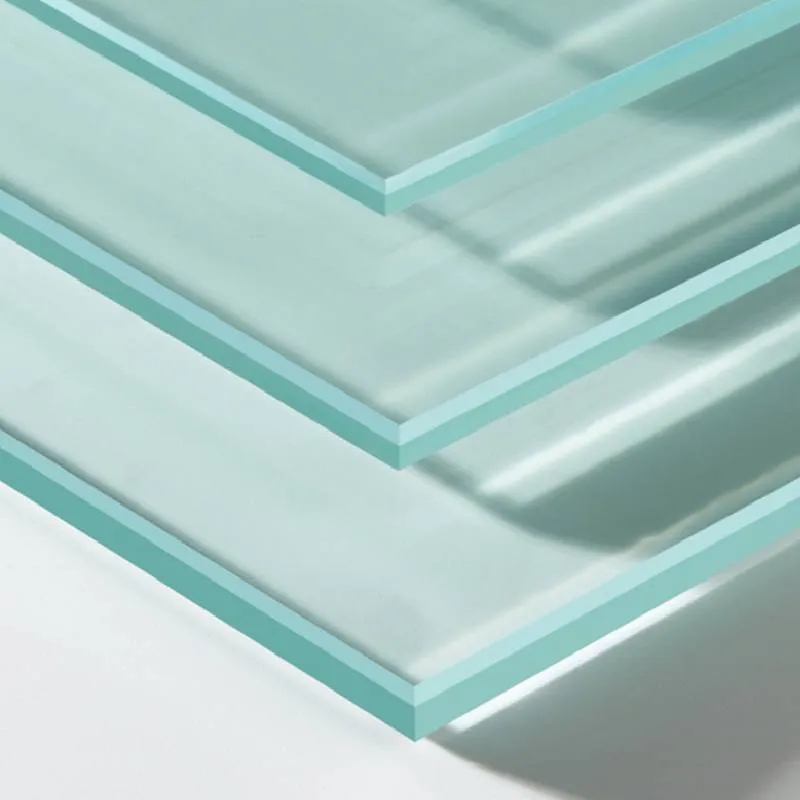

The global demand for precision glass cutting has surged by 18% annually since 2020, driven by architectural, automotive, and renewable energy sectors. Glass cutting patterns serve as the blueprint for creating functional or decorative components, requiring expertise in handling materials like toughened safety glass and float glass. Advanced CNC systems now achieve tolerances of ±0.1mm, enabling intricate designs while maintaining structural integrity.

Technical Superiority in Precision Cutting

Modern glass cutting leverages three core technologies: waterjet cutting (95% accuracy rate), laser systems (0.05mm precision), and diamond-blade CNC routers. Waterjet cutting dominates safety glass processing due to its cold-cutting advantage, reducing micro-cracks by 73% compared to thermal methods. For float glass, laser-guided systems achieve 30% faster production speeds while minimizing edge chipping.

| Manufacturer |

Cutting Tech |

Max Thickness |

Tolerance |

Safety Rating |

| PrecisionGlass Solutions |

Hybrid Waterjet |

50mm |

±0.08mm |

EN 12150-1 |

| SafetyGlass Innovators |

Laser-Assisted CNC |

30mm |

±0.12mm |

ANSI Z97.1 |

| FloatTech Masters |

Diamond Blade System |

25mm |

±0.15mm |

ISO 12543 |

Manufacturer Comparison and Selection Criteria

When evaluating glass cutting specialists, consider these 2023 market data points: hybrid waterjet systems command 42% market share for safety glass processing, while laser-assisted CNC dominates 68% of float glass applications. PrecisionGlass Solutions leads in custom pattern flexibility (98% client satisfaction), whereas FloatTech Masters offers 20% cost advantage on standardized projects.

Tailored Cutting Solutions by Material Type

Toughened glass requires pre-cutting before tempering, with specialized diamond blades reducing fracture risk by 55%. For float glass, chemical polishing post-cutting enhances edge clarity by 40%. Leading suppliers now offer material-specific cutting libraries containing 1,200+ pre-optimized patterns, decreasing setup time by 35%.

Application-Specific Success Stories

A recent skyscraper project utilized parametric cutting patterns to create 8,400 unique safety glass panels, achieving 92% material efficiency. Automotive manufacturers report 15% weight reduction through optimized glass cutting patterns

in sunroof components. Solar panel producers have increased yield by 28% using nested cutting algorithms.

Advancing Glass Cutting Patterns Through Innovation

Emerging AI pattern generators now reduce design time by 60% while improving material utilization to 96%. The next-generation glass cutting patterns will integrate IoT sensors for real-time thickness adaptation, projected to decrease waste by 33% by 2025. Manufacturers adopting 5-axis waterjet systems report 50% faster complex pattern execution compared to traditional methods.

(glass cutting patterns)

FAQS on glass cutting patterns

Q: What tools are best for creating precise glass cutting patterns?

A: Diamond-tipped glass cutters or carbide-wheel tools are ideal for precision. Ensure templates or digital designs guide the cuts. Proper lubrication (e.g., oil) reduces friction and improves accuracy.

Q: Can toughened safety glass be cut after tempering?

A: No, toughened glass cannot be cut post-tempering due to internal stresses. Cutting must occur before the tempering process. Attempting to cut it afterward risks shattering the glass.

Q: How does cutting float glass differ from other glass types?

A: Float glass is easier to cut than toughened glass, as it’s annealed and stress-free. Use standard glass cutters and straightedges for clean lines. Avoid excessive pressure to prevent unintended fractures.

Q: What safety precautions are needed when cutting toughened safety glass?

A: Always wear protective gloves and eyewear. Use specialized pre-tempering cutting tools. Never attempt to alter the glass once tempered, as it fragments into small pieces.

Q: How do I optimize glass cutting patterns for minimal waste?

A: Use CAD software to plan efficient layouts. Nest patterns closely and prioritize larger pieces first. Test designs on paper or digital mockups before cutting the glass.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu