In the realm of modern architecture and interior design, float glass has become an indispensable material, offering unmatched clarity, versatility, and functionality. Understanding the intricacies of float glass manufacturing not only sheds light on its importance but also underscores its transformative potential in various industries.

Float glass manufacturing marks the beginning of a fascinating journey. This process involves the melting of raw materials such as silica sand, soda ash, dolomite, and limestone at approximately 1700°C. The molten mixture is fed onto the surface of molten tin in a bath, where it spreads out and cools, forming a continuous glass ribbon. Due to the even surface of the molten tin, the glass achieves its characteristic flatness, essential for high-quality transparency and optic precision. This meticulous process requires expert control over temperature and material composition, ensuring the resultant glass satisfies rigorous quality standards.

As the float glass emerges from the tin bath, it undergoes annealing, wherein it is slowly cooled in a controlled manner to relieve internal stresses. Experts in the field emphasize that this annealing phase is crucial, as improper cooling can lead to deformation and cracking. Annealing ensures the float glass is robust and reliable, qualities essential for any architectural application. Professional oversight and cutting-edge technology in this phase affirm the industry’s commitment to authoritative manufacturing practices.

Float glass isn't just a product of a complex process; it also exhibits versatile applications that highlight its significance in the product domain. From energy-efficient windows in residential buildings to expansive facades in corporate skyscrapers, the adaptability of float glass is remarkable. Its clear, distortion-free view has become the standard for window installations worldwide. Furthermore, specialized treatments can enhance its properties, such as adding layers for insulation or coatings for UV protection, making it the material of choice for various climatic conditions.

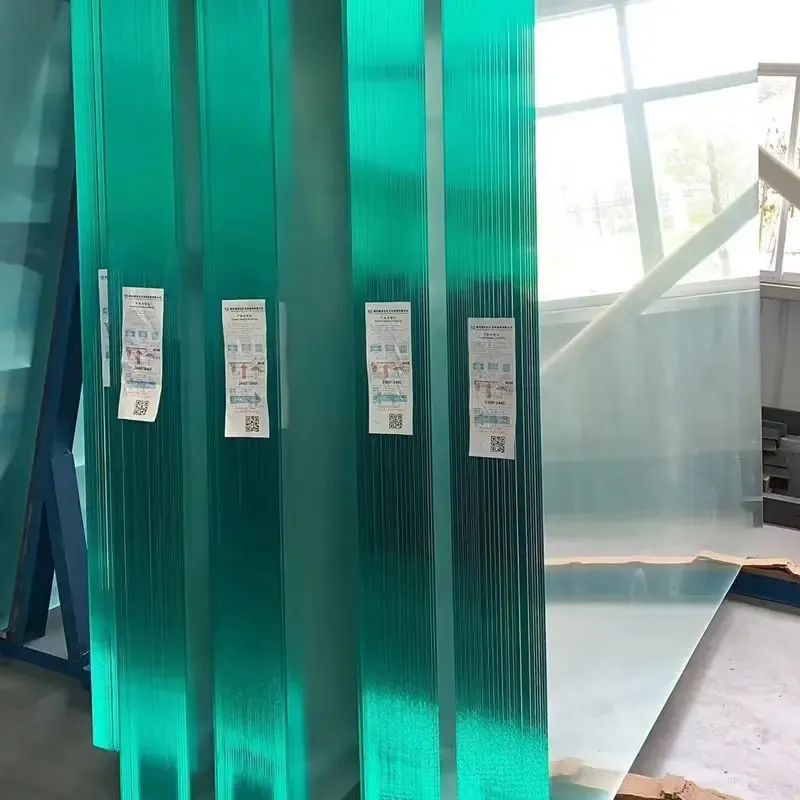

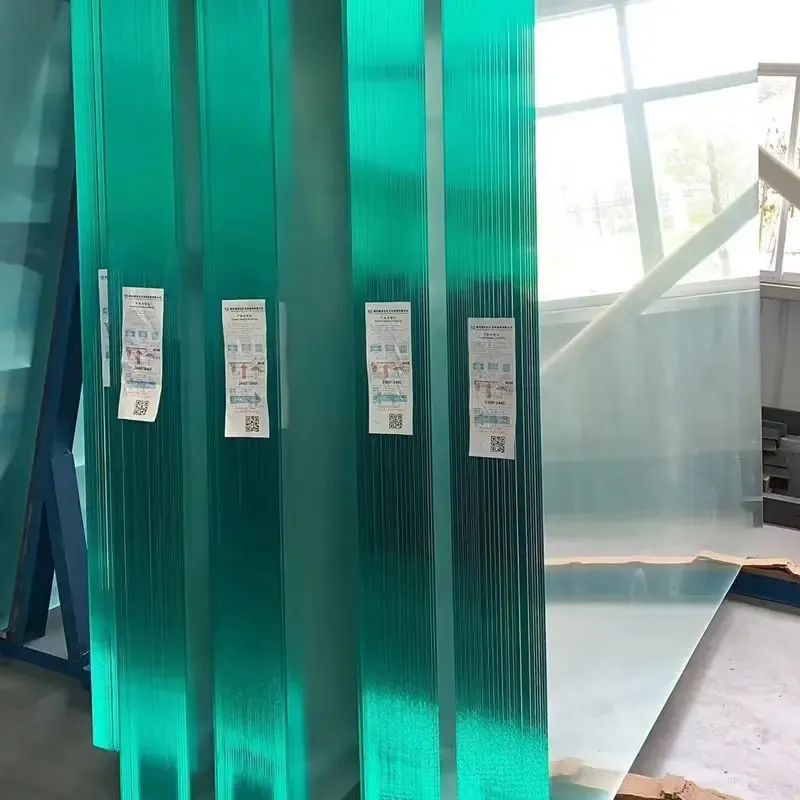

float glass manufacturing

In addition to its architectural uses, float glass finds applications in automobiles, solar panels, and even safety equipment. Automotive industries rely on this glass for its perfect flatness and optical clarity, which are vital for driver safety and comfort. The burgeoning field of renewable energy also capitalizes on float glass, particularly in the manufacturing of photovoltaic solar panels where transparency and durability are paramount.

Trustworthiness in float glass manufacturing is cemented by adherence to stringent international standards and certifications. Manufacturers ensure compliance with safety and quality benchmarks, offering products that clients can trust. Continuous innovation and investment in research and development underscore the industry's dedication to not only meeting but exceeding these standards. This relentless pursuit of excellence reflects a deep-seated expertise and authoritative presence in the global market.

For consumers and professionals sourcing float glass, the reliability of the manufacturing process is non-negotiable. The transparency in manufacturing practices and commitment to quality provide peace of mind, underscoring the trustworthiness of float glass as a fundamental component in modern construction and design.

In conclusion, the float glass manufacturing process embodies a blend of scientific precision, technological innovation, and consistent quality control. Its extensive application in various industries highlights not only its versatility but also the expertise vested in its production. As advancements continue, float glass remains a testament to engineering excellence and a trusted choice for energy efficiency, safety, and aesthetics.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu