- Fundamental definitions and creation processes of specialized glass types

- Surface characteristics and light diffusion properties compared

- Manufacturing techniques for safety glass versus conventional glass

- Technical performance analysis with comparative data metrics

- Leading manufacturer capabilities and industry benchmarks

- Custom design possibilities for functional applications

- Practical implementation scenarios across different industries

(what is the difference between etched and frosted glass)

Understanding Core Variations in Specialty Glass Production

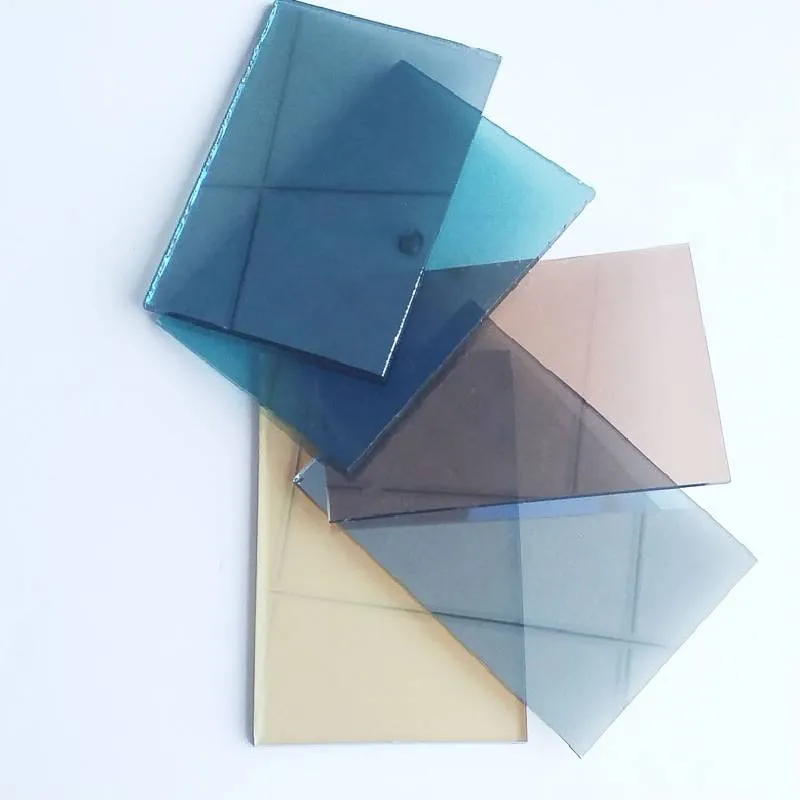

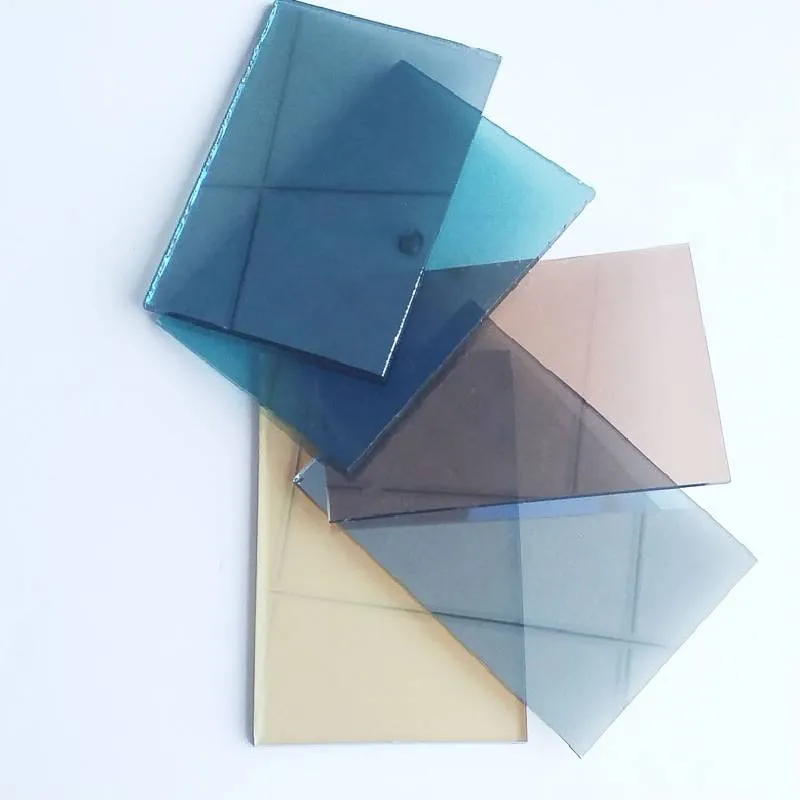

Distinct production methods create significant differences between glass types despite some visual similarities. Etched glass undergoes either chemical or mechanical abrasion that physically alters its surface texture. Skilled artisans often incorporate custom designs during the engraving process which becomes permanent. Frosted glass typically uses sandblasting or acid treatments to create a uniform matte finish that scatters light. Both techniques yield translucent results but through fundamentally different material modifications.

Light Transmission and Surface Texturing Properties

The interaction between light and glass surfaces reveals critical functional differences. Etched patterns can create varying levels of translucency depending on depth - shallow engravings might permit 70-80% light transmission while deeper cuts reduce visibility to 40-50%. This technique allows controlled transparency across different pattern zones. Frosted glass scatters light uniformly due to micro-abrasions across the entire surface, typically permitting 50-60% light diffusion regardless of viewing angle.

Surface integrity differs substantially: Etching physically removes glass material creating grooves and depressions clearly detectable by touch. Frosting creates microscopic surface disruptions that feel smooth yet significantly reduce transparency. This surface-level frosting differentiates it from etched applications where design depth dictates both tactile and visual qualities.

Safety Glass Manufacturing Processes Explained

Tempered glass undergoes extreme thermal processing to enhance structural properties. This manufacturing process involves heating glass panels to approximately 650°C followed by rapid cooling that creates balanced internal tension patterns. Regular float glass (annealed glass) cools slowly at room temperature without additional treatment. The tempering process increases durability by 4-5 times compared to untreated glass.

When broken, the safety characteristics become critically apparent: Tempered glass fractures into small pebble-like pieces without sharp edges, meeting international safety standards including ANSI Z97.1 and European EN12150. Regular glass shatters into dangerous shards and jagged fragments that pose severe injury risks. This fundamental safety difference necessitates tempered glass applications in buildings, vehicles and commercial environments where impact resistance remains paramount.

Technical Performance Metrics Analysis

| Characteristic |

Etched Glass |

Frosted Glass |

Tempered Glass |

Regular Glass |

| Impact Resistance |

Similar to substrate material |

Similar to substrate material |

4-5x stronger |

Baseline strength |

| Thermal Shock Threshold |

≈180°F |

≈180°F |

≈450°F |

≈180°F |

| Surface Hardness (Mohs) |

5.5-6.5 |

5.5-6.5 |

5-6 |

5-6 |

| Break Pattern |

Based on substrate |

Based on substrate |

1cm² fragments |

Dangerous shards |

| Cost Premium |

20-40% |

15-30% |

25-60% |

Standard cost |

Manufacturer Technologies and Material Capabilities

Leading producers like Corning and Guardian have developed specialized etching systems capable of precision tolerances under 0.1mm. Industrial frosting techniques from manufacturers such as Pilkington feature proprietary acid formulas applied uniformly across large panels exceeding 10m² surface areas. Saint-Gobain's tempering ovens process automotive glass at rates exceeding 2,500 panels daily with consistent hardness measurements between 550-650 N on the Knoop hardness scale.

Quality benchmarks dictate that tempered glass must withstand compression levels exceeding 10,000 psi - verified through impact tests dropping steel balls weighing 227g from heights of 2m without fracture. These performance thresholds exceed conventional glass capabilities by substantial margins. Thermal shock resistance in tempered glass allows survival through temperature differentials exceeding 270°F without compromising structural stability.

Design Customization and Functional Applications

Etched glass permits nearly limitless customization potential using CNC precision routing that achieves depths from .02mm to 3mm. Architectural applications frequently incorporate corporate logos etched at precise depths maintaining 60% translucency. Frosted surfaces provide enhanced privacy solutions suitable for healthcare partitions where 90% light diffusion balances visibility discretion with ambient illumination.

Safety requirements dictate tempered glass applications in critical settings including balcony barriers (minimum 12mm thickness), glass stair treads (laminated with 1.52mm PVB interlayer) and high-traffic retail partitions. These installations follow building codes mandating minimum surface compression of 10,000 psi. Decorative processes including ceramic frit printing applied before tempering provide lasting solutions for branding applications in corporate environments.

Practical Implementation Across Diverse Industries

Surgical facilities widely implement etched sterilization indicators on autoclave doors where chemical alterations verify sterilization cycles. Pharmaceutical labs utilize acid-frosted containment barriers for chemical fume hoods maintaining uniform light diffusion. Tempered glass shower enclosures remain mandatory in residential construction under modern building codes, typically requiring 6-8mm thickness with fully tempered certification labels permanently etched in corners.

Commercial kitchen environments demonstrate hybrid solutions: Interior partitions employ 8mm frosted glass reducing visual distractions while service counters require 12mm tempered panels withstanding impacts from serving trays. This combination balances safety requirements with functional design considerations. Future innovations include switchable smart glass technologies that electronically transition between transparent and frosted states suitable for conference rooms and advanced privacy implementations.

Selecting Between Etched, Frosted, Tempered and Regular Glass Options

Determining suitable glass applications requires evaluating aesthetic, functional and safety parameters. Decorative projects requiring intricate custom designs benefit from etching techniques. Projects needing uniform diffusion and privacy select acid-frosted alternatives. High-traffic commercial installations demand tempered safety glass compliance with building regulations. Budgetary constraints may permit regular glass only in fixed interior applications without safety concerns.

Durability testing data supports specifying tempered glass wherever impacts, thermal shifts or breakage risks exist. The substantial cost differential between tempered and regular glass becomes justified through life-safety protections and reduced liability exposure. Surface treatments like etching and frosting may be applied to tempered substrates, offering creative possibilities while maintaining structural integrity. This layered functionality approach produces glass solutions meeting technical specifications without aesthetic compromise.

(what is the difference between etched and frosted glass)

FAQS on what is the difference between etched and frosted glass

Q: What is the difference between etched and frosted glass?

A: Etched glass uses acid or sandblasting to create permanent decorative patterns, altering the surface texture. Frosted glass has a uniformly blurred appearance achieved through sandblasting or coatings. Both obscure visibility, but etching allows custom designs while frosted glass offers consistent opacity.

Q: How does tempered glass differ from regular glass?

A: Tempered glass is heat-treated for strength and shatters into small, safe granules when broken. Regular glass (annealed) breaks into sharp shards. Tempered glass is 4-5 times stronger but cannot be cut after tempering.

Q: Is there a difference between tempered and normal glass in durability?

A: Yes, tempered glass undergoes thermal processing to enhance impact resistance and thermal shock tolerance. Normal glass lacks this treatment, making it more prone to cracking. Tempered versions are mandatory for safety-critical applications like car windows.

Q: Can etched glass be used for structural purposes?

A: No, etching only modifies surface appearance and light diffusion, not structural integrity. For load-bearing needs, tempered or laminated glass should be used. Etching works best for decorative partitions or doors where strength isn’t primary.

Q: Why choose tempered glass over standard glass for windows?

A: Tempered glass provides superior safety during breakage and withstands greater wind pressure. Standard glass poses injury risks from sharp fragments. Building codes often require tempered glass in high-traffic or overhead installations like skylights.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu