Toughened Plain Glass An Overview

Toughened plain glass, also known as tempered glass, has become an essential material in various industries, including architecture, automotive, and furniture design. Characterized by its strength and safety features, this type of glass undergoes a meticulous manufacturing process that enhances its durability while still maintaining clarity and aesthetic appeal.

The Manufacturing Process

The production of toughened plain glass begins with regular glass, which is typically composed of silica sand, soda ash, and limestone. This glass is first cut to the desired dimensions and then subjected to a high-temperature heating process. It is heated to approximately 600 degrees Celsius, transforming its surface properties. After reaching this temperature, the glass is rapidly cooled through a process called quenching. This cooling phase is critical; it induces compressive stresses on the surface of the glass while creating tensile stresses within, significantly enhancing its overall strength.

This process can increase the strength of the glass up to five times greater than that of ordinary, untreated glass. As a result, toughened glass is highly resistant to impact, thermal stress, and even bending. Its ability to withstand high temperatures makes it suitable for environments where thermal fluctuations are common, such as in kitchen settings or near fireplaces.

Safety Features

One of the standout characteristics of toughened plain glass is its safety. When broken, it shatters into small, blunt pieces rather than sharp shards, greatly reducing the risk of injury. This feature is particularly valuable in public spaces such as schools, restaurants, and office buildings, where safety is a paramount concern. This makes toughened glass an optimal choice for both structural and decorative applications.

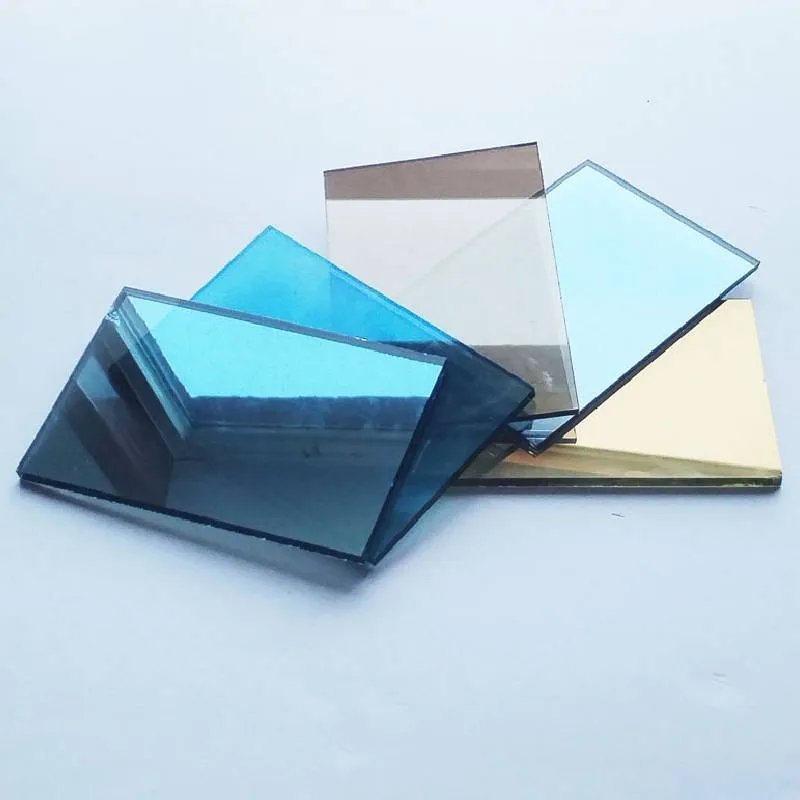

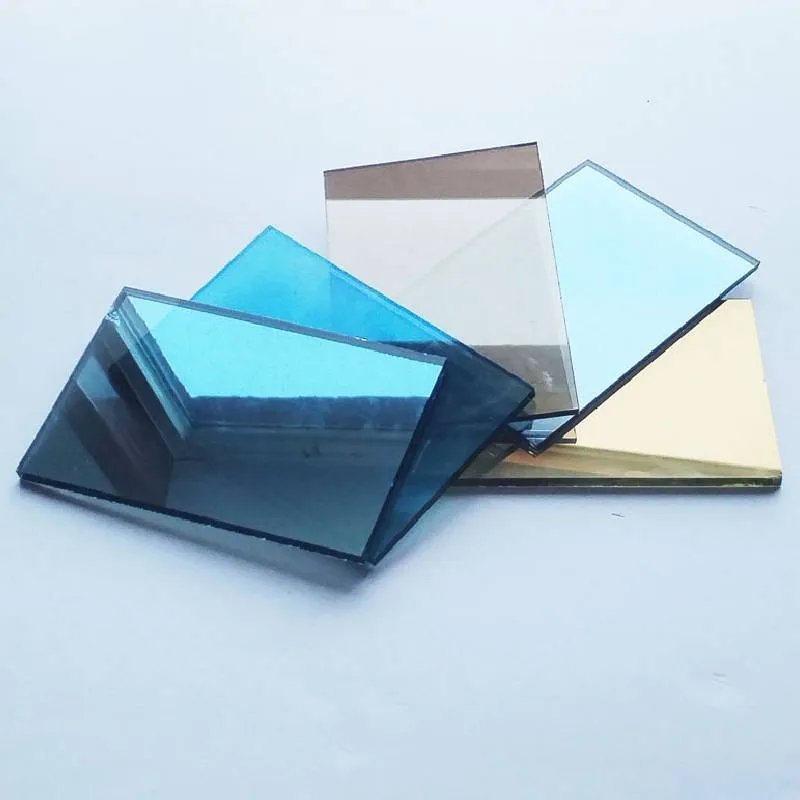

toughened plain glass

Applications Across Industries

Toughened plain glass has a wide range of applications. In architectural design, it is used for windows, glass doors, facades, and partition walls, allowing for expansive views and natural light while ensuring safety and energy efficiency. In the automotive industry, it is utilized for windshields and side windows, as its high strength and safety features protect occupants in the event of an accident.

Moreover, toughened glass is a popular choice in the furniture industry. It is commonly used in tabletops, shelves, and display cases, combining elegance with resilience. Many manufacturers appreciate its ease of maintenance, as it is less prone to scratches and stains compared to traditional glass.

Environmental Considerations

As a product, toughened plain glass is also relatively environmentally friendly. Glass is 100% recyclable, and creating toughened glass can be done with recycled materials. This enhances its sustainability credentials, aligning with the growing demand for eco-friendly materials in construction and design.

Conclusion

Toughened plain glass has emerged as a versatile material celebrated for its strength, safety, and aesthetic appeal. Whether in architecture, automotive manufacturing, or furniture design, its applications are vast and growing. As industries continue to innovate and prioritize safety and sustainability, the demand for toughened glass is likely to increase, solidifying its place as a cornerstone material in contemporary design and construction. With ongoing advancements in technology, we can expect to see even more exciting developments and uses for this incredible material in the future.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu