The float glass manufacturing process is a cornerstone of modern architecture and design, providing the high-quality glass used in windows, doors, and a multitude of other applications. This method revolutionized the glass industry, bringing about a level of precision and efficiency previously unattainable. For those involved in construction, design, or the glass manufacturing industry, understanding this process is essential for making informed decisions about materials.

At the heart of the float glass process is the idea of creating a smooth, flat glass sheet without the need for expensive polishing and grinding. This groundbreaking method was developed in the 1950s by Pilkington and has since become the global standard. It involves floating molten glass on a bed of molten tin. The basic procedure includes several critical stages melting, floating, annealing, and cutting.

The process begins in the furnace, where raw materials such as silica sand, soda ash, and limestone are heated to a temperature exceeding 1700°C. This extreme heat turns the mixture into a molten state. The meticulous control of raw material ratios and temperature in the furnace environment is vital, ensuring the consistency and clarity of the glass produced.

Once the glass has reached the desired molten consistency, it is carefully poured onto a bath of molten tin. Due to gravity and surface tension, the molten glass spreads across the tin, forming a perfectly even sheet. This integration of glass and tin occurs in a highly controlled environment to prevent oxidation and impurities, which can compromise the quality of the glass.

As the glass floats on the tin, it slowly cools. It’s essential at this phase to ensure that cooling is precise and gradual to avoid internal stresses that can lead to brittleness or breaking. This phase occurs in what is known as the annealing lehr, a controlled cooling chamber that gradually reduces the glass temperature, allowing it to solidify evenly without introducing weaknesses.

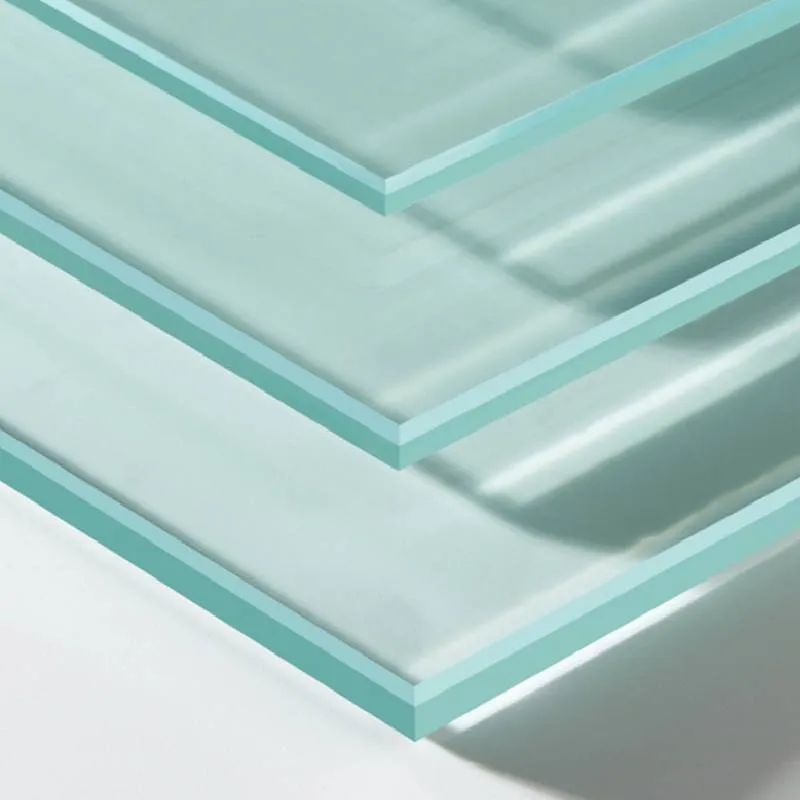

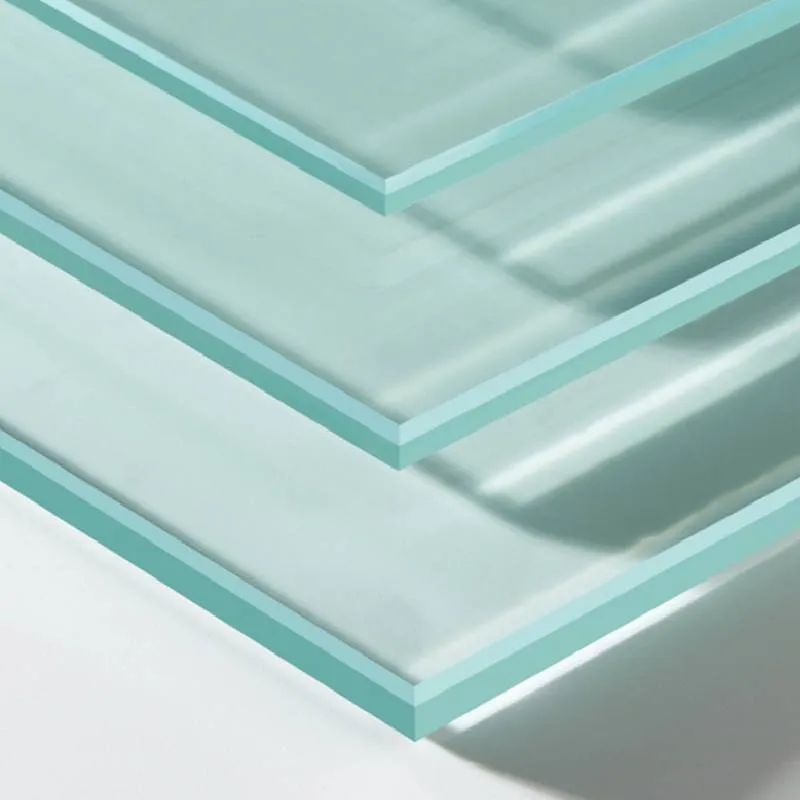

float glass manufacturing process

Once the glass sheet emerges from the annealing lehr, it is inspected for quality. Modern technology allows this inspection to be both visual and automated, ensuring even the tiniest flaw is detected. Defective areas are marked and cut away, maintaining the high standard that float glass is known for. Standard dimensions are then cut from the continuous ribbon of glass to suit commercial needs, with any leftover glass being recycled back into the process.

Expertise in the float glass manufacturing process means understanding the critical balance between precision and efficiency. Professionals in the field know that minor adjustments in temperature, atmosphere, or speed can significantly impact the quality of glass produced. Thus, continual training, research, and technological advancement are crucial to maintaining high product standards.

This process's authority comes from its widespread adoption and success, evidenced by its use in over 90% of the world's glass production.

The end product is a testament to the trustworthiness and reliability that float glass manufacturing promises. Businesses and consumers alike benefit from glass that is durable, aesthetically pleasing, and versatile.

In conclusion, the float glass manufacturing process is not merely a production method but a testament to human innovation and engineering excellence. Its widespread success and continual development stand as proof of its efficiency and reliability, making it a key player in modern material technology. As we look to the future, the process will undoubtedly evolve, driven by an ever-growing demand for excellence in glass production and application.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu