Tempered glass, also known as toughened glass, is a type of safety glass that has been heat-treated to increase its strength and thermal resistance. The process of manufacturing tempered glass involves several critical steps, ensuring that the final product is durable and can withstand significant stresses and thermal changes.

The first step in the tempered glass process begins with selecting high-quality float glass as the base material. Float glass is a smooth, flat material that is made by floating molten glass on a bed of molten tin. This provides a uniform thickness and clarity, making it an ideal candidate for further processing.

Once the float glass has been selected, it is cut to the desired dimensions using precision cutting tools. The edges are then polished to eliminate sharp corners, making it safer to handle and reduces the risk of chipping or breaking during further processing. After cutting and polishing, the glass is thoroughly cleaned to remove any impurities, dust, or grease that could affect the tempering process.

The next stage involves heating the glass to a temperature of approximately 620 to 650 degrees Celsius (about 1148 to 1202 degrees Fahrenheit). This heating is done in a specialized furnace that evenly distributes the heat across the glass surface. The goal of this step is to ensure that the glass reaches a uniform temperature throughout, setting the stage for the next phase of the tempering process.

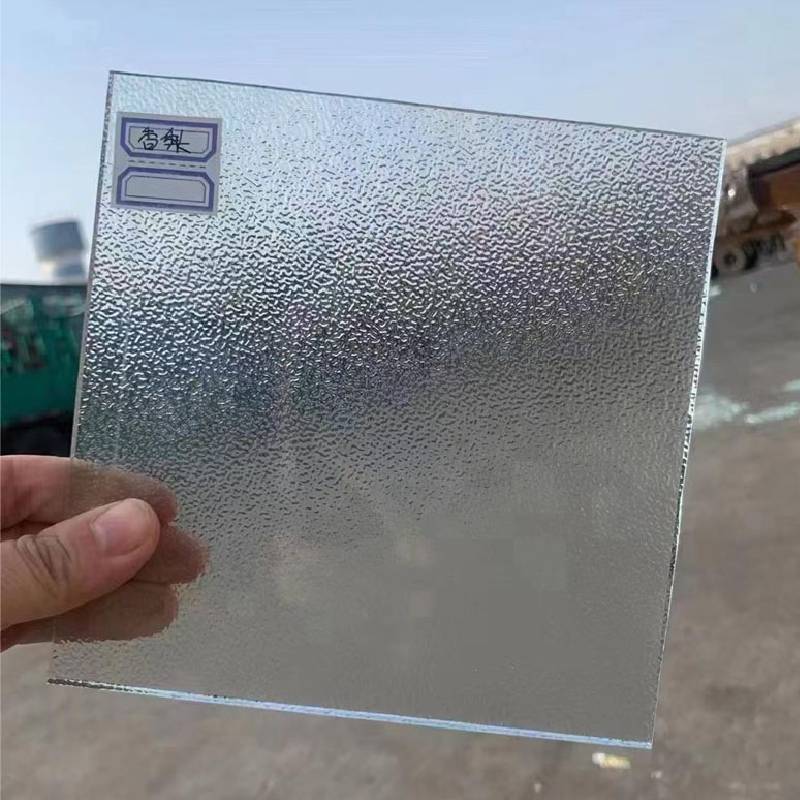

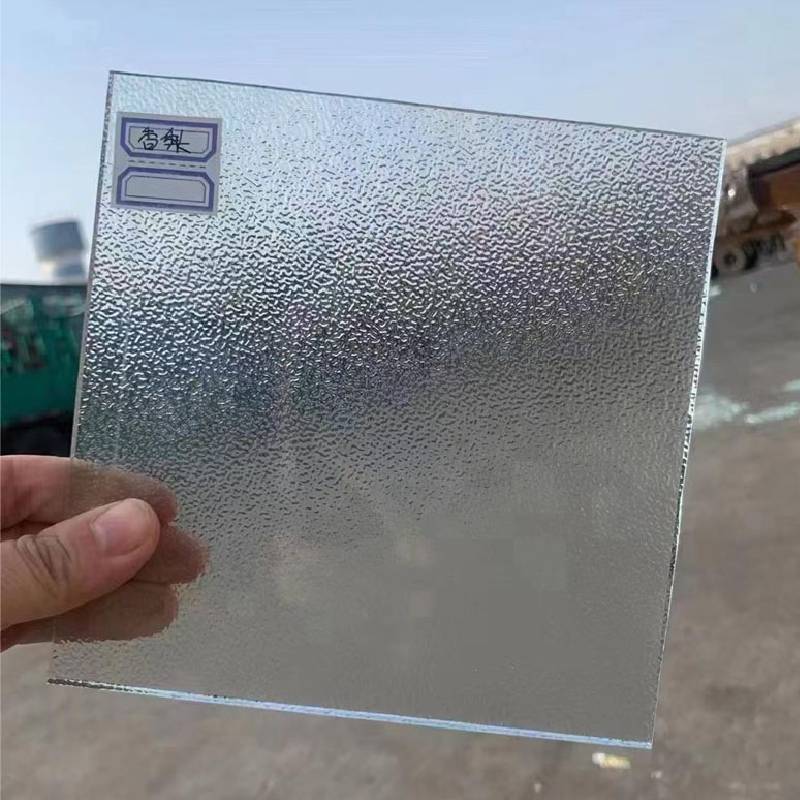

tempered glass process

Once the glass has reached the requisite temperature, it is rapidly cooled using high-pressure air. This cooling phase, known as quenching, is critical as it creates a significant difference in temperature between the surface and the interior of the glass. The outer surface cools quickly, while the inner part retains heat for a longer period. This process induces compressive stresses on the surface and tensile stresses in the center, resulting in a glass that is much stronger than untreated glass.

The final step in the tempered glass process involves inspecting the finished product for any defects. Each sheet of tempered glass is rigorously tested to ensure it meets safety standards and specifications. Additionally, tempering significantly increases the glass's resistance to thermal shock, allowing it to endure sudden temperature fluctuations without breaking.

In conclusion, the tempered glass process is a sophisticated series of steps that transforms ordinary glass into a robust material suitable for various applications, including windows, shower doors, and glass doors. Its strength, safety, and aesthetic appeal make tempered glass an essential choice in modern architecture and design.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu