The Manufacturing Process of Float Glass A Comprehensive Overview

Float glass, known for its superior quality and clarity, is an essential material in a wide array of industries, from construction to automotive. The manufacturing of float glass involves a meticulous process that ensures its strength, smoothness, and transparency. This article delves into the intricacies of float glass manufacturing, outlining its key stages, the technology involved, and the significance of quality control.

At the heart of float glass production is the float process, which was invented in the 1950s by Sir Alastair Pilkington. This innovative technique revolutionized glass manufacturing by producing a glass surface that is remarkably flat and free of distortions. The process begins with the careful selection of raw materials, including silica sand, soda ash, and limestone. These components are mixed in precise proportions to create a batch that can be transformed into glass.

Once the raw materials are prepared, they are subjected to intense heat in a furnace that reaches temperatures around 1,700 degrees Celsius (3,092 degrees Fahrenheit). Here, a chemical reaction occurs, melting the materials into molten glass. The quality of the glass at this stage is crucial, as any impurities can affect the final product. After the glass is melted, it flows onto a bath of molten tin. This is where the magic of the float process happens the glass spreads out and forms a uniform layer, thanks to the buoyancy of the tin. This method ensures that both surfaces of the glass are perfectly flat, resulting in the high clarity that float glass is known for.

As the glass sheet moves along the tin bath, it gradually cools and solidifies. Once it reaches the end of the bath, the newly formed glass is called “float glass.” It is then cut into manageable sheets for further processing. The thickness of the float glass can be adjusted during production, allowing manufacturers to cater to various applications, from thin glass for windows to thicker plates for structural uses.

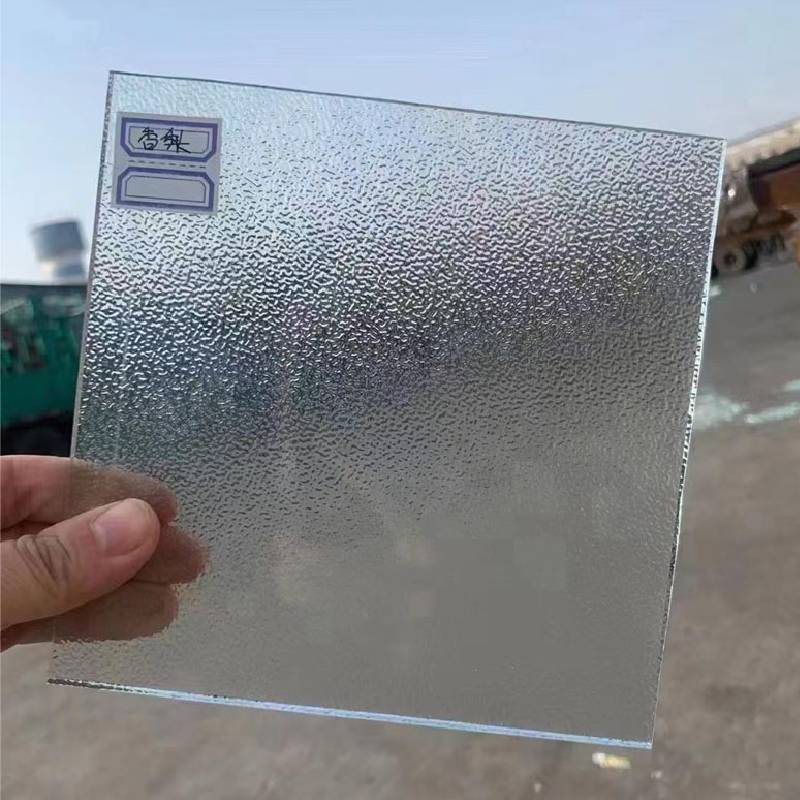

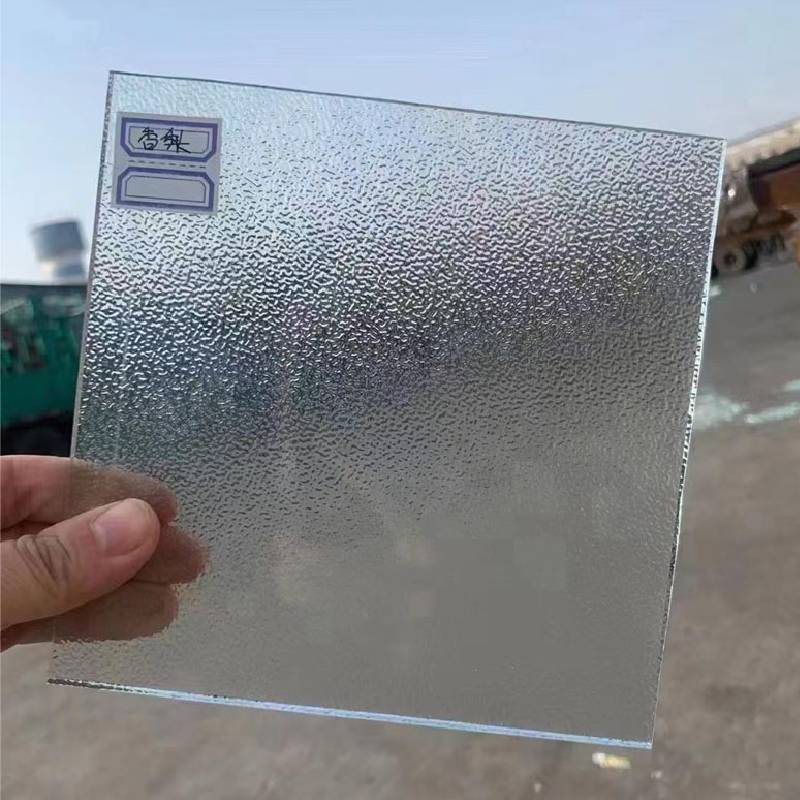

float glass manufacturing plant

The next crucial step in float glass manufacturing is annealing. After cutting, the glass sheets pass through an annealing lehr, a controlled heating and cooling chamber. This process is essential for relieving internal stresses within the glass that could lead to breakage. As the glass cools slowly, it also ensures a consistent thickness and enhances overall durability. Following annealing, the glass sheets are carefully inspected to identify any defects, such as bubbles or scratches.

Quality control is a continuous aspect of float glass manufacturing. Advanced technology is often employed, including automated inspection systems that use cameras and sensors to detect imperfections in real-time. This attention to detail ensures that only the highest quality glass reaches the market and meets safety standards.

In addition to traditional float glass, manufacturers can also produce specialized variants, such as low-emissivity (low-E) glass, which reflects heat, enhancing energy efficiency in buildings. Laminated and tempered glasses add to the versatility of float glass, offering safety features and aesthetic options for consumers.

The environmental impact of float glass manufacturing is also an important consideration. Modern plants increasingly focus on sustainability, employing strategies to reduce energy consumption and manage waste effectively. Techniques like recycling cullet (recycled glass) not only minimize raw material usage but also lower the melting temperature needed, leading to reduced energy costs.

In conclusion, the float glass manufacturing process is a complex yet fascinating blend of art and science. From the careful selection of raw materials to the advanced technology used in quality control, each step plays a critical role in producing the high-quality glass that is so widely utilized today. As the demand for glass continues to grow, innovations in manufacturing practices will likely enhance efficiency and sustainability, ensuring that float glass remains a vital component in modern society.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu