The float glass manufacturing process is an innovative and precise production method that holds a significant place in modern industry due to its efficiency and high-quality outputs. This advanced process involves several crucial steps, each contributing to the production of flawless sheets of glass which are essential in various applications ranging from architecture to automotive and beyond.

At the onset of the float glass manufacturing, raw materials such as silica sand, soda ash, limestone, and dolomite are meticulously weighed and mixed in precise proportions. These materials are fundamental as they form the glass's chemical structure and impart necessary properties. The mixture is then fed into a furnace that operates at an astonishing temperature, often exceeding 1700°C. This high temperature ensures that the raw materials melt thoroughly, creating a homogenous, molten glass mixture free of imperfections.

Once the melt attains the desired consistency, it is gently poured onto a bath of molten tin. Herein lies the ingenuity of the float glass process; the tin bath provides a perfectly flat and level surface due to its high density compared to molten glass.

As the glass floats on this liquid tin, it naturally spreads out and forms a uniform thickness. This floating process is critical, as it eliminates the need for mechanical rollers which might otherwise impart imperfections or irregularities on the glass surface.

The glass then undergoes a controlled cooling phase known as annealing, facilitated in a structure called a lehr. This step is paramount as it removes internal stresses within the glass, avoiding future breakage or warping when subjected to temperature changes or mechanical stress. The annealed glass emerges from the lehr with enhanced strength and durability, marking it ready for further processing or direct distribution.

float glass manufacturing process

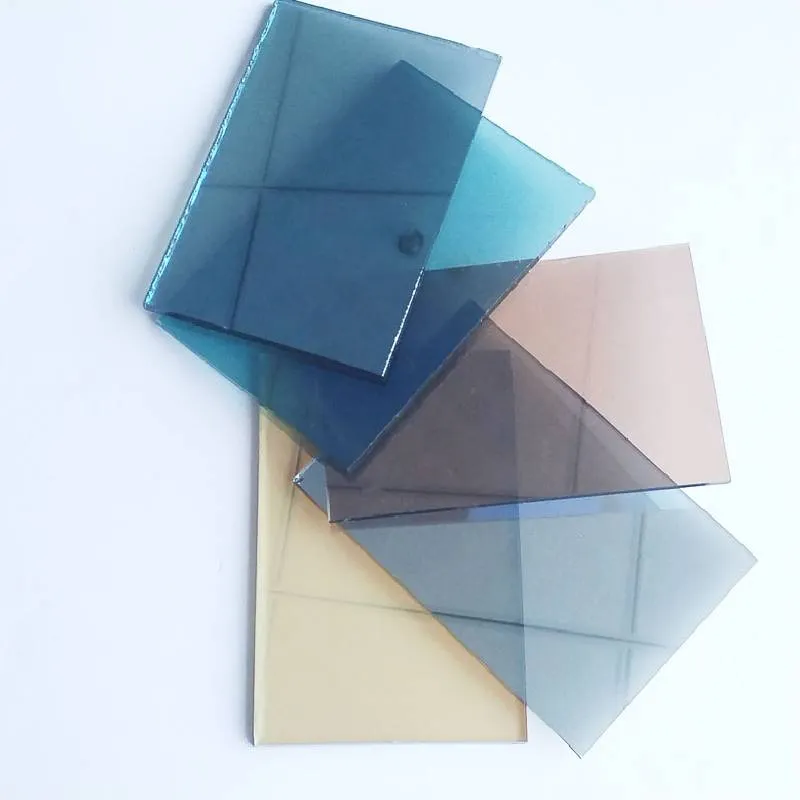

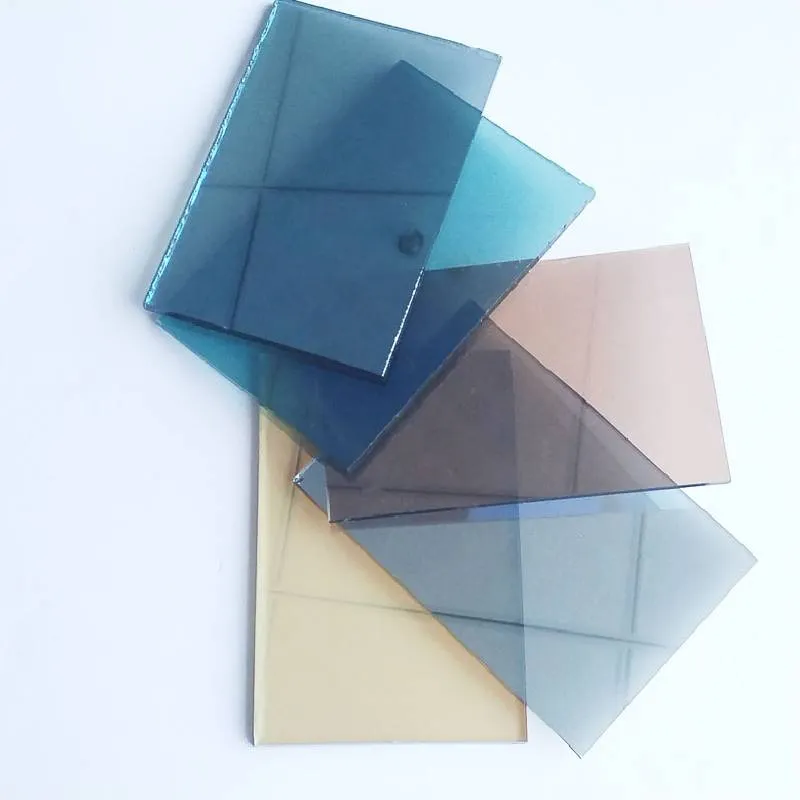

One remarkable aspect of float glass is its versatility. Once the basic glass sheet is produced, it can be customized in numerous ways to meet specific industry requirements. Techniques such as lamination, coating, or tempering can be applied, each delivering unique properties suitable for different applications. For example, tempered glass, which is cooled rapidly, is used where safety is paramount due to its tendency to shatter into small grains rather than sharp shards when broken.

The expertise involved in the float glass process does not only lie in the chemistry and mechanics of its production but also in the sustainability measures implemented. Modern manufacturing plants are equipped with technologies designed to minimize emissions and recycle materials. This reflects a commitment not only to quality and expertise but also to environmental stewardship.

In conclusion, the float glass manufacturing process exemplifies a blend of scientific precision and industrial innovation. It stands as a testament to human ingenuity, delivering a product that is both versatile and essential across a multitude of sectors. This process is not only about producing a material but doing so with a commitment to expertise, quality, and environmental responsibility, ensuring trustworthiness in every sheet of glass produced.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu