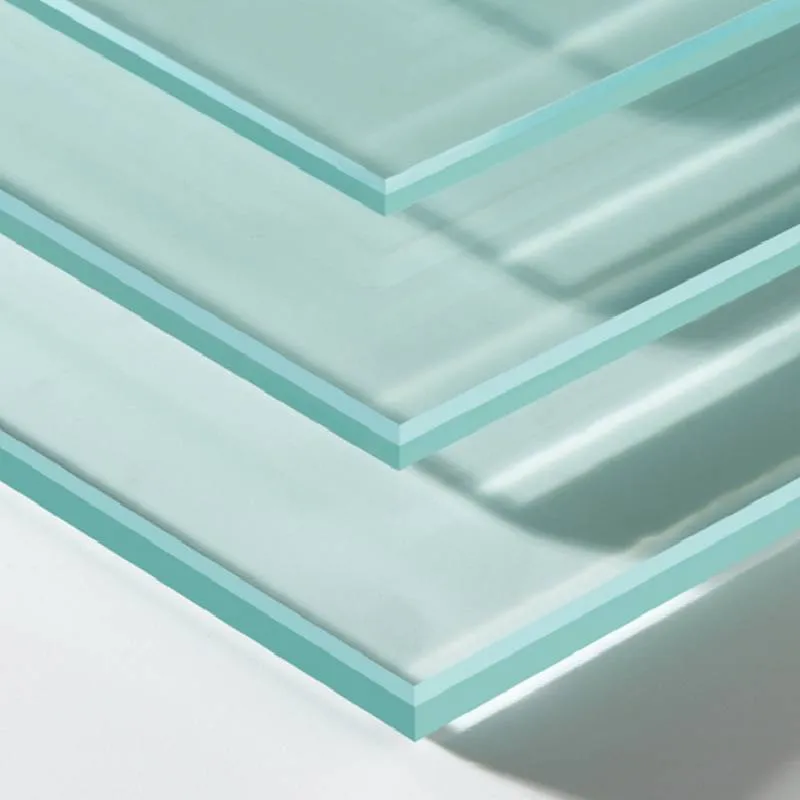

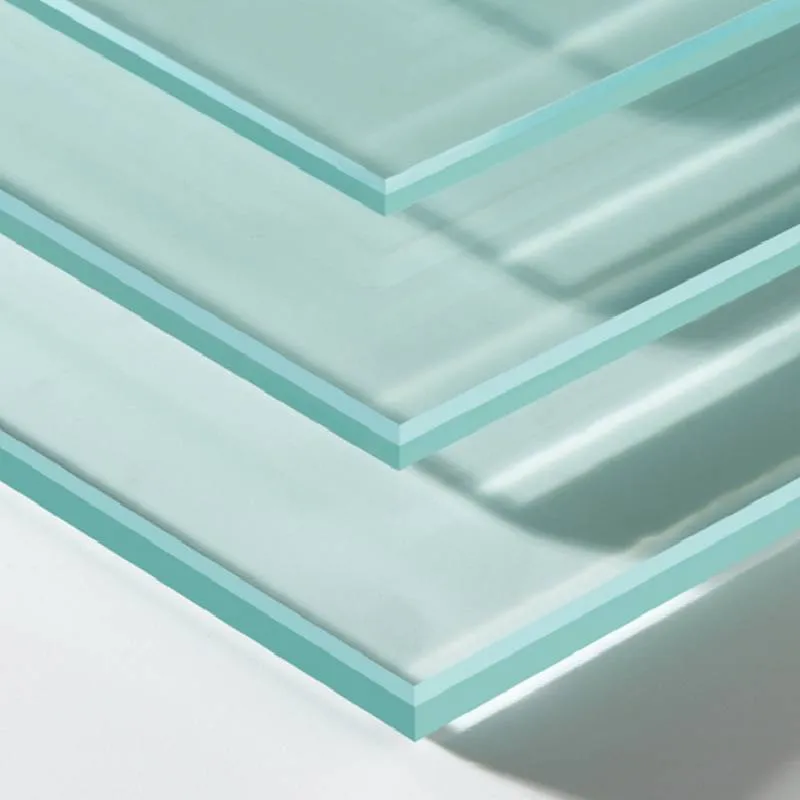

The glass toughening process is an intricate operation that involves converting ordinary glass into a more robust, safer, and vastly more versatile material. This methodology has gained prominence across various industries due to its efficacy in enhancing the durability and safety of glass products. As a seasoned expert in the field, I will delve into the nuances of this process, laying bare its intricacies and its paramount importance in today's glass manufacturing landscape.

Toughened glass, also known as tempered glass, is produced through a process of extreme heating followed by rapid cooling. This treatment imparts strength to the glass, making it several times stronger than untreated glass. Through systematic heating, the surface layers of the glass reach high temperatures before being cooled quickly, leading to compression stress on the surface and tension stress inside. These opposing stresses contribute to the glass's increased strength, ensuring that it is not only durable but also safer in case of shattering.

This process is indispensable for its safety features. If broken, toughened glass fractures into small, blunt pieces, minimizing the risk of injury. This feature makes it particularly appealing in environments where safety is paramount, such as in automotive manufacturing, construction, and even in household items. The automotive industry, for instance, relies heavily on toughened glass for vehicle windows, where the unique properties of the material can protect passengers in the event of an accident.

Moreover, toughened glass's robustness extends its applications to architectural designs, wall facades, and even in home appliances. Its ability to withstand significant temperature changes without compromising structural integrity is invaluable in industries where durability and reliability are critical.

glass toughened process

The technological sophistication behind the toughening process is underpinned by scientific rigor. The precision in achieving the right temperature and cooling rate is crucial, necessitating meticulous control over the parameters in industrial settings. Technicians and engineers engage in continuous research to refine these processes, ensuring that the glass produced meets stringent standards of performance and safety. Industry certifications and standards, such as those from the American National Standards Institute (ANSI) or the British Standards (BS), underscore the importance of compliance and the credibility of manufacturers.

From an authoritative standpoint, toughened glass represents a crucial advancement in material science, specifically tailored to address both functional and safety needs. Collaboration among scientists, engineers, and industry experts has propelled the development of innovative solutions that cater to evolving demands across sectors. Given the constant advancement in technology, the methodologies employed in the glass toughening process are continuously optimized for efficiency and efficacy.

Trustworthiness in the production of toughened glass is fundamental. Consumers and industry stakeholders alike must be assured of the quality and safety of the glass they utilize. Manufacturers achieve this by adhering to regulated testing protocols and providing transparent information regarding the characteristics of toughened glass. By doing so, they demonstrate a commitment to delivering a product that is both reliable and secure.

In conclusion, the glass toughening process is a testament to the intersection of engineering excellence, safety imperatives, and scientific innovation. It stands as an exemplar of how ingenuity and meticulous engineering can transform a fundamental material into one that meets the ever-changing needs of modern society. Its development continues to be rooted in a blend of experience, expertise, and an unwavering commitment to quality and safety, warranting its critical role across multiple applications and industries.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu