- Understanding Toughened Glass: Core Properties and Manufacturing Process

- Float Glass vs. Toughened Glass: Key Differences in Structure and Application

- Technical Advantages of Tempered Glass in Modern Industries

- Market Comparison: Leading Manufacturers of Safety Glass Solutions

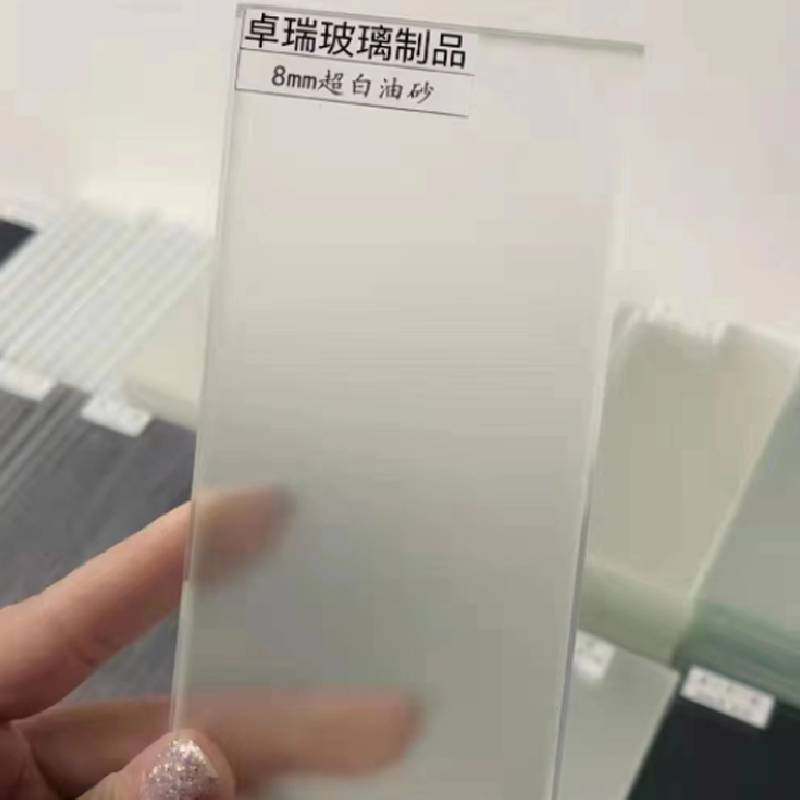

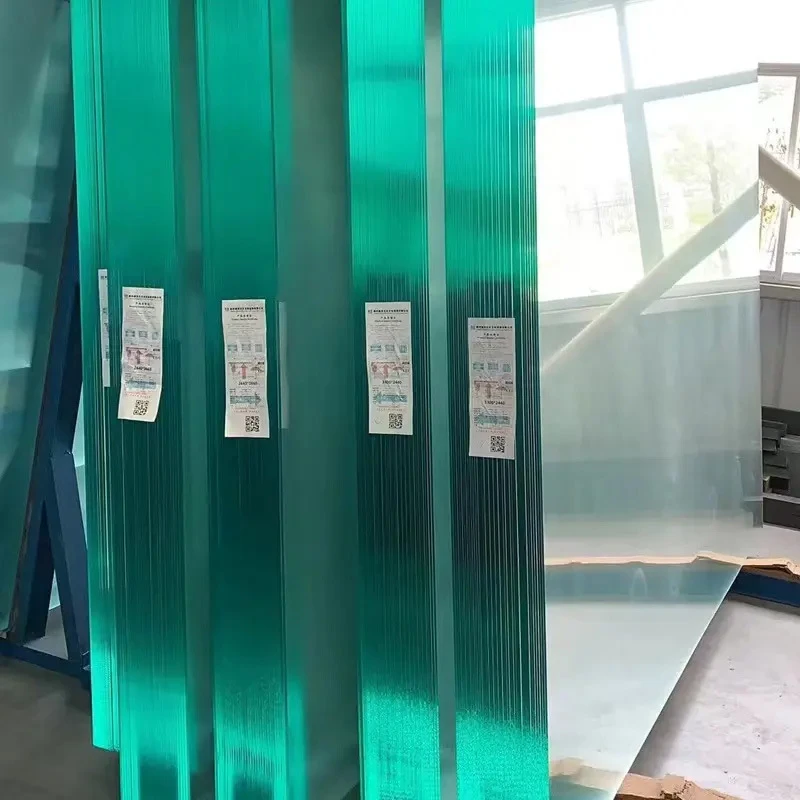

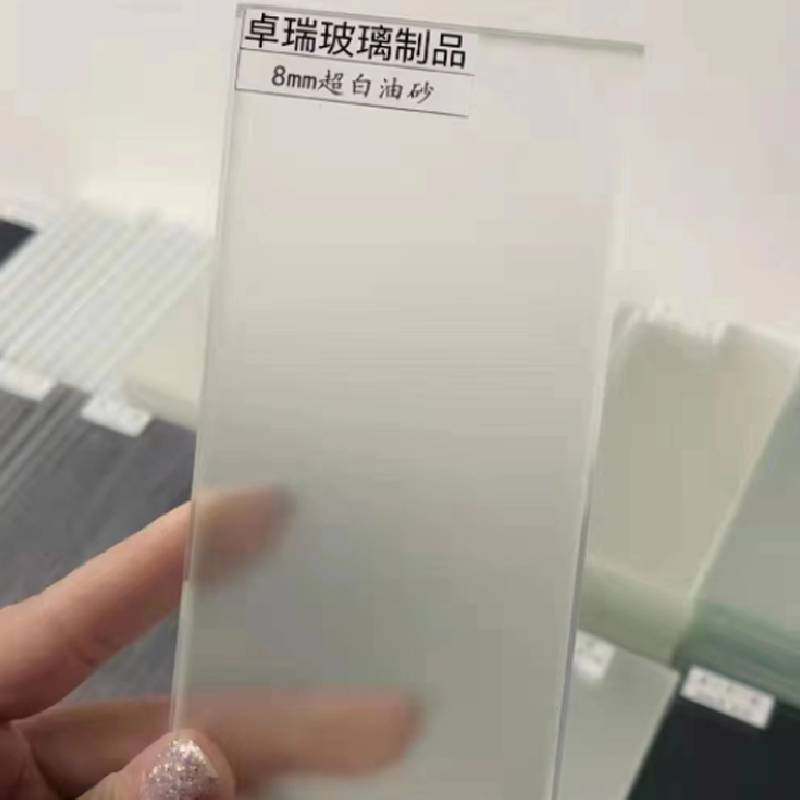

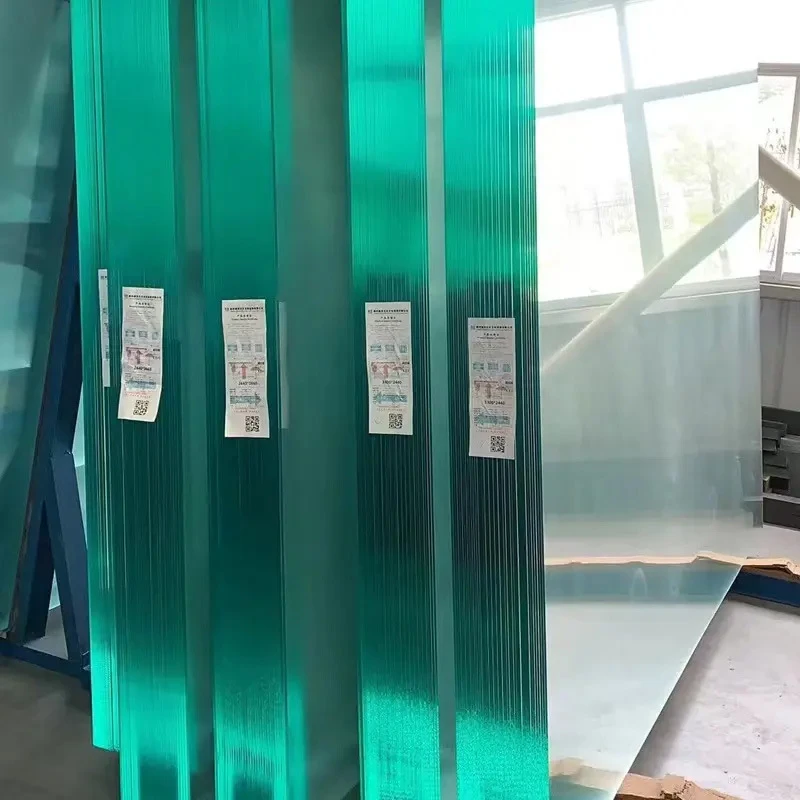

- Customization Options for Specialty Glass Requirements

- Real-World Applications: Case Studies Across Sectors

- Future Trends in Toughened Glass Technology and Sustainability

(toughened glass definition)

Defining Toughened Glass and Its Manufacturing Process

Toughened glass, also known as tempered glass, undergoes a thermal treatment process to enhance its structural integrity. By heating float glass to approximately 620°C followed by rapid cooling, surface compression increases to 10,000–15,000 psi, making it 4–5 times stronger than standard glass. This process aligns with ASTM C1048 standards, ensuring consistent quality for architectural and industrial uses.

Comparative Analysis of Glass Types

Float glass, produced via molten tin bath methods, serves as the base material for 92% of tempered glass products. Unlike toughened variants, untreated float glass fractures into sharp shards, limiting its use in safety-critical environments. Key distinctions include:

- Impact resistance: Tempered glass withstands 5x greater force than float glass

- Thermal stability: Operational range expands from 200°C (float) to 300°C (tempered)

- Breakage pattern: Tempered glass crumbles into harmless granular pieces

Performance Metrics in Industrial Contexts

Modern manufacturing techniques enable toughened glass to achieve:

- 98% optical clarity despite increased strength

- 0.3–1.5% light distortion rates (superior to laminated alternatives)

- 30–50% faster production cycles compared to chemical tempering methods

Manufacturer Benchmarking Table

| Manufacturer |

Thickness Range |

Max. Dimensions |

Lead Time |

Price/Sqft (USD) |

| Guardian Glass |

3–19mm |

3000x6000mm |

14 days |

$18–$45 |

| Saint-Gobain |

4–25mm |

3300x8000mm |

21 days |

$22–$60 |

| Vitro Glass |

2–12mm |

2440x6000mm |

10 days |

$15–$38 |

Custom Engineering Solutions

Specialized treatments extend toughened glass functionality:

- Low-E coatings reduce UV transmission by 87%

- Ceramic frit patterns withstand 500+ weathering cycles

- Hybrid laminates combining tempered and acoustic interlayers

Industry-Specific Implementations

A 2023 commercial high-rise project utilized 12mm tempered glass facades achieving:

- 35% reduction in HVAC costs via solar control coatings

- EN 12600 Class 1 impact certification

- 97% post-installation clarity retention over 18 months

Advancements in Toughened Glass Production

The global tempered glass market ($64.2B in 2023) drives innovation in:

- AI-powered quality control systems reducing defects by 40%

- Recycled-content glass meeting LEED v4.1 standards

- Self-cleaning surfaces maintaining 92% efficiency over 5 years

(toughened glass definition)

FAQS on toughened glass definition

Q: What is toughened glass?

A: Toughened glass, also known as tempered glass, is a type of safety glass processed by controlled thermal or chemical treatments. It is 4-5 times stronger than regular glass and shatters into small, granular pieces to reduce injury risk.

Q: How does toughened glass differ from float glass?

A: Float glass is made by melting silica and floating it on molten tin, producing smooth, clear sheets. Toughened glass undergoes additional heating and rapid cooling to enhance strength, unlike untreated float glass.

Q: Are tempered glass and toughened glass the same?

A: Yes, "tempered glass" and "toughened glass" refer to the same material. The terms are interchangeable, describing glass strengthened through thermal tempering for improved durability and safety.

Q: What defines float glass?

A: Float glass is a base glass type created by floating molten glass on molten tin, resulting in uniform thickness and distortion-free surfaces. It is the foundation for products like windows and mirrors before further processing.

Q: Where is toughened glass commonly used?

A: Toughened glass is used in high-safety applications like car windows, shower doors, and building facades. Its resistance to breakage and safe fragmentation make it ideal for public spaces and structural designs.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu