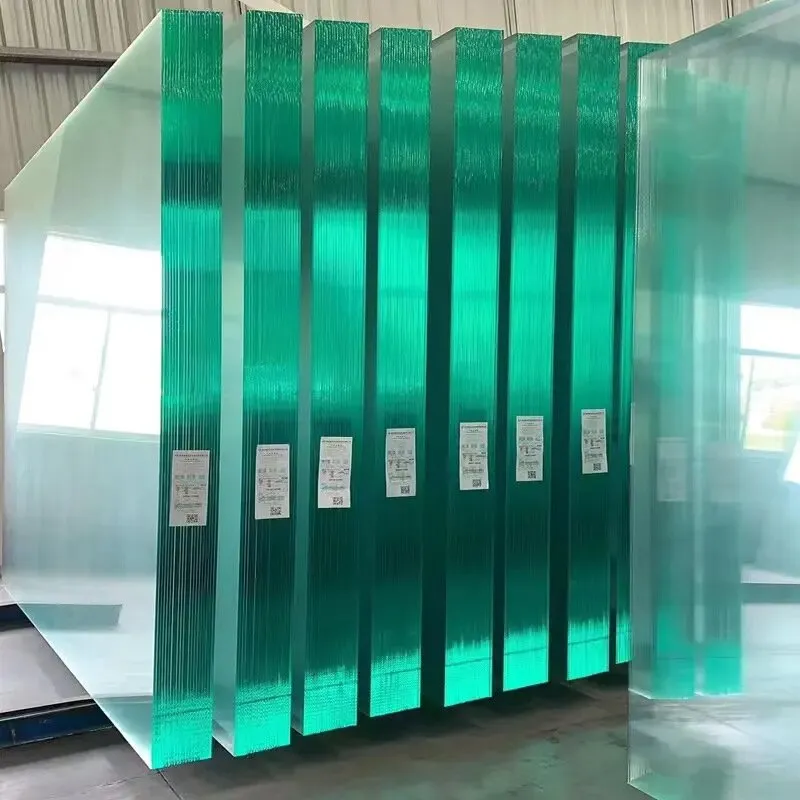

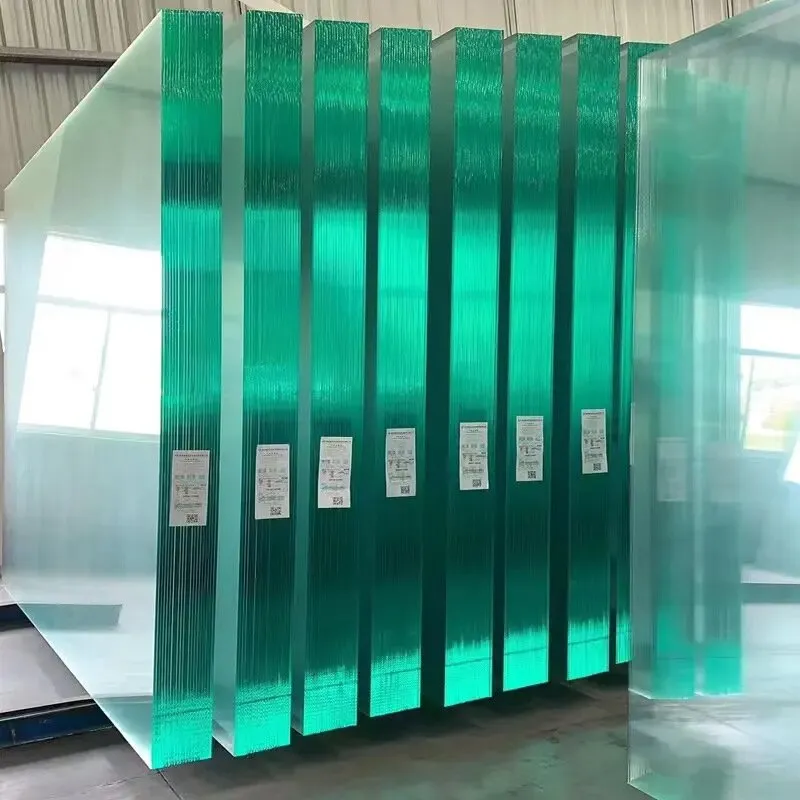

Tempered glass, a critical component in various industries, is renowned for its strength, safety, and durability. This hardened glass is manufactured through a specialized process that enhances its properties, making it an essential material in sectors ranging from automotive to architecture. The manufacturing process of tempered glass is a sophisticated procedure that demands expertise and precision to meet stringent industry standards.

The journey of tempered glass begins with the selection of high-quality raw glass. This base glass is inspected rigorously to ensure it is devoid of impurities, blemishes, or inconsistencies that could compromise the final product's integrity. Typically, the glass selected for tempering is annealed glass, which is initially more prone to thermal stress.

Once the raw glass is verified for quality, it undergoes a cutting process. Precision cutting tools are employed to achieve the exact dimensions required for its intended application. It is within this stage that the glass edges are polished or seamed to remove any nicks or sharp edges, ensuring the glass does not shatter during the subsequent heating process.

The core of the tempering process lies in the heating phase. The glass sheets are loaded onto a conveyor belt that transports them into a tempering furnace. This furnace, equipped with advanced convection and radiation systems, heats the glass uniformly to temperatures exceeding 600 degrees Celsius. This precise heating method is crucial as it redistributes internal stressors, which in turn, affects the glass's tensile strength and resilience against impacts.

Following the heating, the glass undergoes rapid cooling, or quenching, in a controlled manner. Jet streams of cool air are blasted onto the glass surfaces, a pivotal step that causes the external layers of the glass to cool more swiftly than the inner layers. This differential cooling induces compressive stress on the exterior while keeping the core in tension, a characteristic that awards tempered glass its formidable strength.

manufacturing process of tempered glass

Each phase of tempered glass manufacturing is meticulously monitored to maintain the integrity of the process. Computerized systems track temperature, conveyor speed, and quenching intensity, ensuring that the glass meets the industry's exact standards. The end result is a sheet of glass that is not only up to five times stronger than untreated glass but also safer. Should it break, tempered glass shatters into small, harmless pieces rather than sharp shards.

Given the complexities of the tempered glass manufacturing process, only seasoned professionals with profound expertise in glass technology and material science are suited to oversee production. Their expertise ensures adherence to both safety protocols and quality standards, providing assurance to clients and end-users alike over the product's reliability and performance.

Moreover,

manufacturers often subject tempered glass batches to rigorous testing. This includes impact resistance tests where samples are exposed to force or stress to observe failure points. Optical inspections are conducted as well to detect any irregularities or distortions that could affect usability, particularly for automotive or architectural applications where clarity and precision are paramount.

The intricate artistry behind tempered glass manufacturing highlights its significance in today’s diverse industrial applications. Manufacturers who succeed in producing high-quality tempered glass not only demonstrate technical prowess but also instill trust and build authority within the market. Clients and consumers alike benefit from a material distinguished by its enhanced safety features, reliability, and overall robustness, making tempered glass a stalwart choice in ensuring quality and safety across numerous products and structures.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu