Tempered glass is made through a process called tempering, which involves heating annealed (regular) glass to a high temperature and then rapidly cooling it.

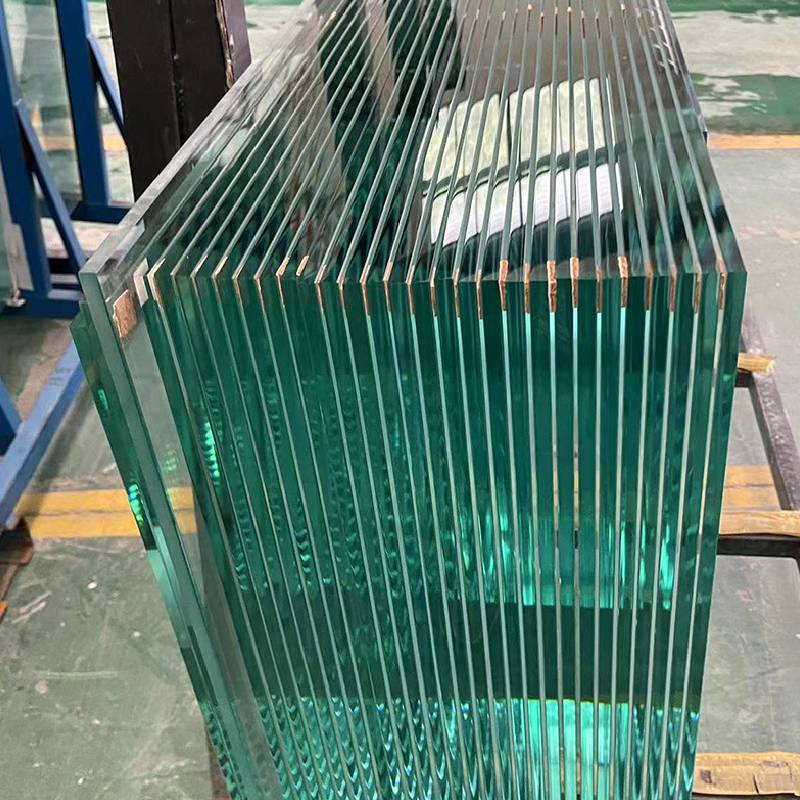

Cutting: The first step in the process is to cut the glass to the desired size and shape.

Cleaning: Once the glass is cut, it is thoroughly cleaned to remove any dirt, dust, or contaminants from the surface.

Heating: The cleaned glass is then placed into a tempering oven, which heats it to a temperature of around 620-680 degrees Celsius (1150-1250 degrees Fahrenheit).

Quenching: After the glass reaches the desired temperature, it is quickly cooled by blasting it with jets of cold air or by immersing it in a bath of cold water or oil.

Annealing: Once the glass is tempered, it undergoes a process called annealing to relieve the internal stress and strengthen the glass further. This involves heating the glass to a lower temperature and then slowly cooling it in a controlled manner. Annealing helps to ensure the stability and durability of the tempered glass.

Strength: Tempered glass is significantly stronger than regular glass of the same thickness. It can withstand higher impact forces and is less likely to break upon impact. This makes it an ideal choice for applications where safety is a concern, such as in windows, doors , shower enclosures, and automotive windows.

Safety: When tempered glass does break, it shatters into small, blunt pieces rather than sharp shards. This reduces the risk of injury from sharp edges, making tempered glass safer for use in environments where breakage is a possibility.

Heat Resistance: Tempered glass has higher thermal resistance compared to regular glass. It can withstand sudden changes in temperature, such as exposure to hot or cold liquids, without shattering. This property makes it suitable for use in oven doors, cookware, and fireplace screens .

Manufacturing Process: Tempered glass is produced by heating annealed (regular) glass to a high temperature and then rapidly cooling it using air jets or quenching it in a bath of cold water or oil. This process creates internal stress within the glass, giving it its characteristic strength and safety features.

Tempered glass is used in a wide range of applications, including residential and commercial windows, glass doors, glass partitions, shower enclosures, tabletops, and automotive windows. Its strength and safety properties make it a popular choice in construction, automotive, and consumer electronics industries.

Overall, tempered glass offers enhanced strength, safety, and heat resistance compared to regular glass, making it a versatile and widely used material in various industries and applications.

The inspection standards for tempered glass mainly include the following aspects:

Fragmentation status: Different types of tempered glass have different requirements for their fragmentation status. For example, when the thickness of Class I tempered glass is 4mm, take 5 samples for testing, and the mass of the largest fragment among all 5 samples shall not exceed 15g. When the thickness is greater than or equal to 5mm, the number of fragments in each sample within the 50mm*50mm area must exceed 40.

Mechanical strength: The mechanical strength of tempered glass includes compression resistance, bending resistance and impact resistance. There are three inspection methods: tensile test, bending test and impact test.

Thermal stability: The thermal stability of tempered glass refers to its tolerance and deformation ability in high temperature environments. Inspection methods include differential thermal analysis, thermal expansion test, etc.

Size and deviation: The size of tempered glass is agreed upon by both the supplier and the buyer, and the allowable deviation of its side length should meet certain standards.

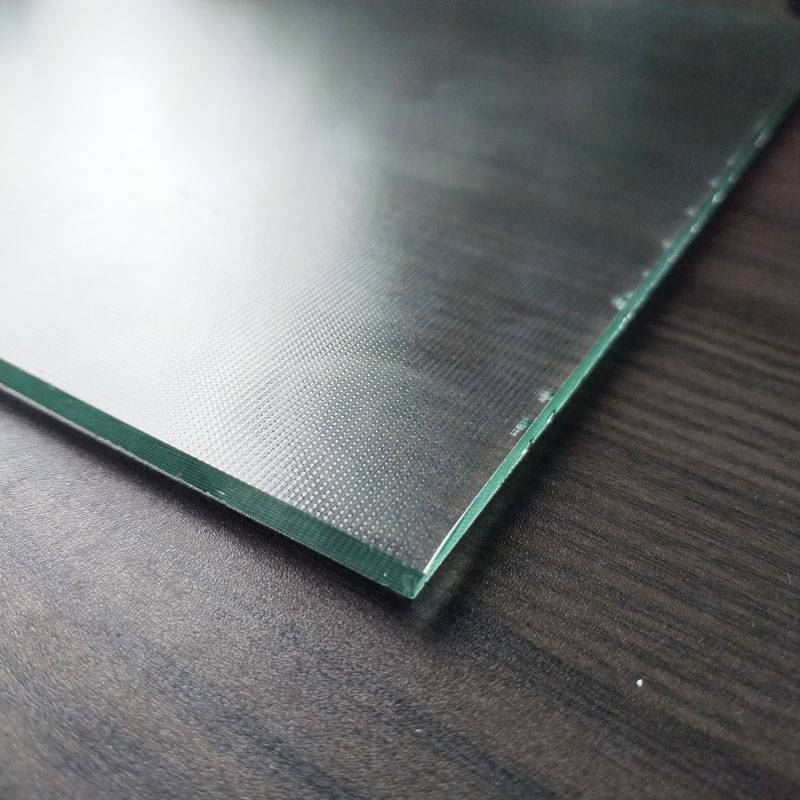

Appearance quality: The appearance quality of tempered glass must comply with certain regulations, including but not limited to hole diameter, hole position allowable deviation, etc.

Recommended national standards and industry standards for tempered glass testing include:

GB15763.2-2005 Safety glass for construction Part 2: Tempered glass: This standard specifies the basic requirements, test methods and inspection rules for safety glass for construction.

GB15763.4-2009 Safety glass for construction Part 4: Homogeneous tempered glass: This standard specifies the basic requirements, test methods and inspection rules for homogeneous tempered glass for construction.

JC/T1006-2018 Glazed tempered and glazed semi-tempered glass: This standard specifies the technical requirements, test methods and inspection rules for glazed tempered and glazed semi-tempered glass.

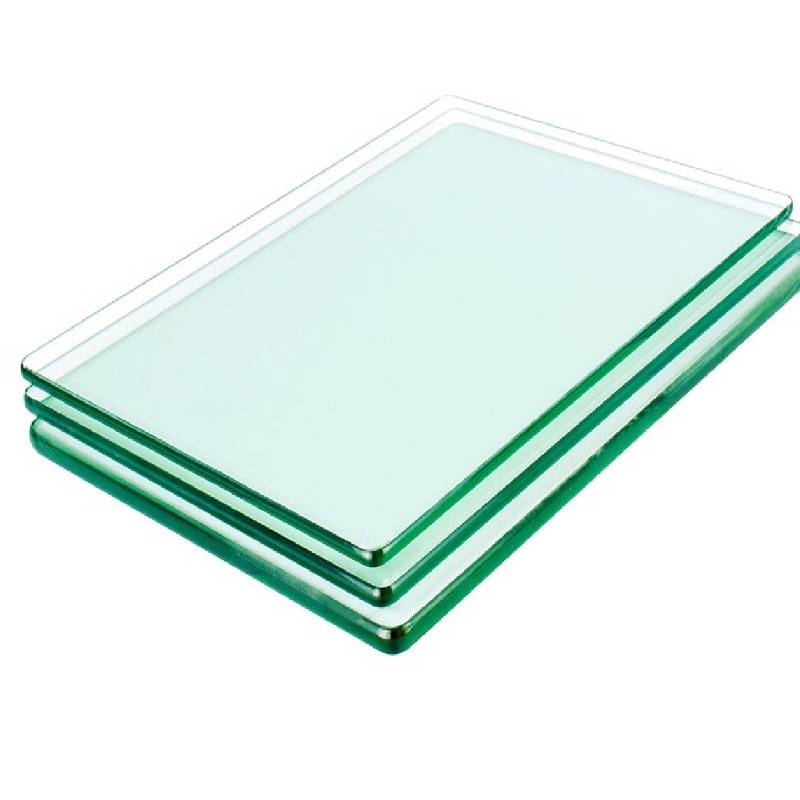

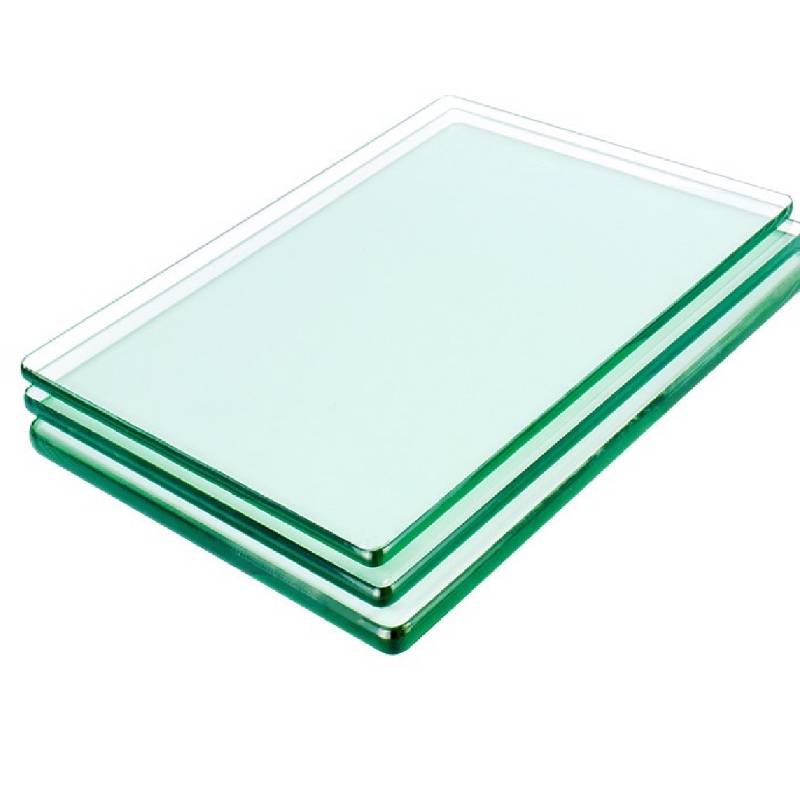

Thickness: 3.2mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm

Size: customized according to customer requirements.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu