Innovative Surface Engineering: Nashiji Pattern Glass Technology

The global architectural glass market is projected to reach $111.8 billion by 2027 (Glass Magazine, 2023), with patterned glass accounting for 18% of the specialty segment. 3mm and 4mm Nashiji obscure pattern glass represents a breakthrough in surface engineering, offering the perfect balance between light diffusion and privacy maintenance.

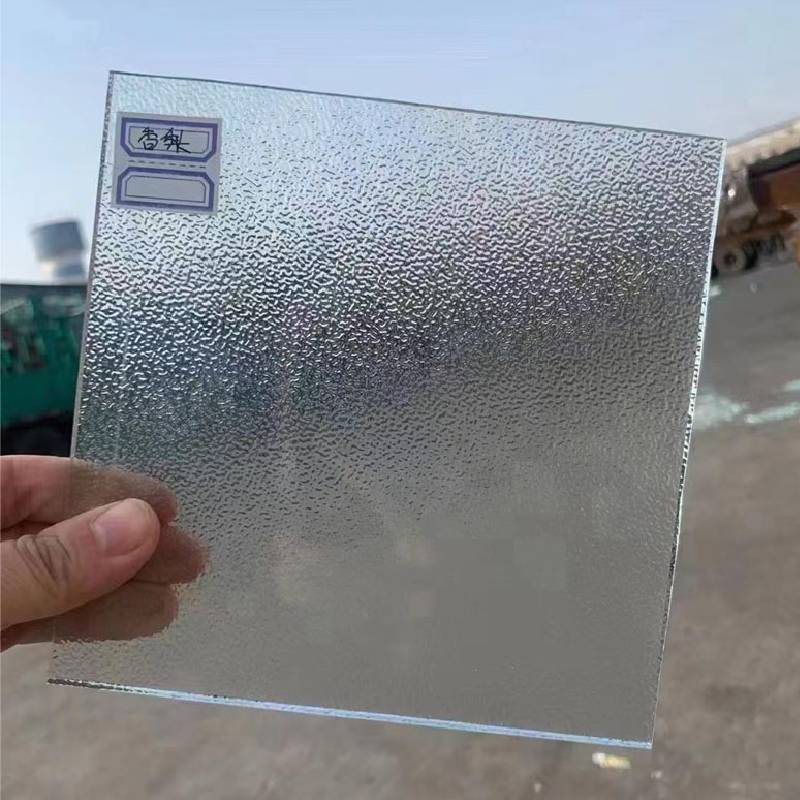

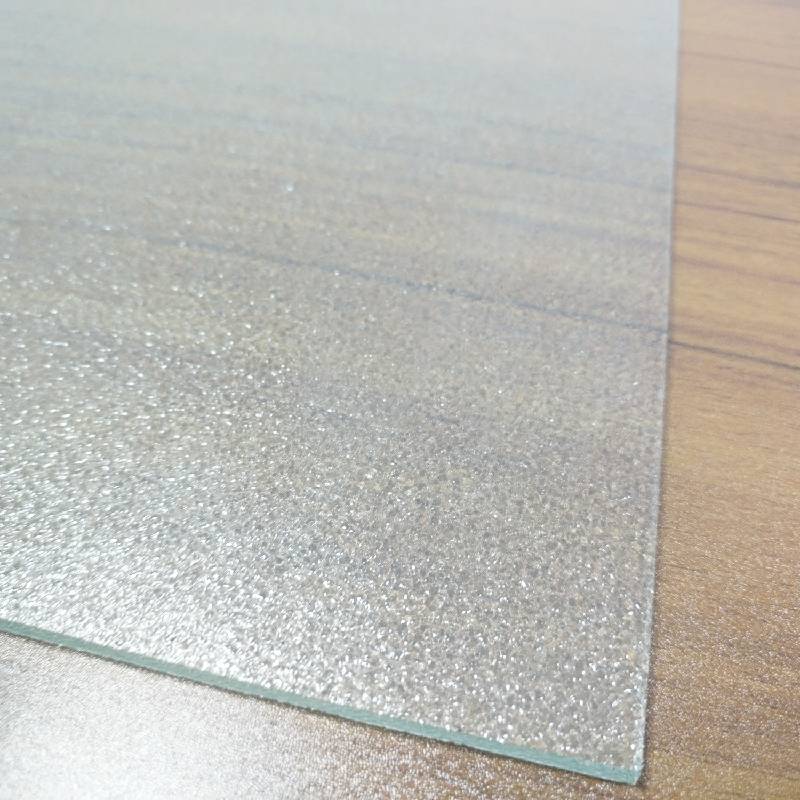

Manufactured through an advanced rolling process, Nashiji pattern glass features a distinctive textured surface resembling hammered metal. This unique treatment causes light to refract in multiple directions, achieving the "obscure" effect that transmits 92% of visible light while effectively blocking image transmission. Glass Technology Quarterly notes this makes it "ideal for contemporary privacy solutions in commercial and residential spaces" (2023).

Technical FAQ: Nashiji Glass Properties

Q: What's the annealing process for Nashiji glass?

A: Our glass undergoes controlled annealing at 550-570°C for 90 minutes followed by gradual cooling at 1.5°C/minute to relieve internal stresses, ensuring compliance with EN 572 tempering standards.

Q: Can Nashiji glass be laminated?

A: Yes, both 3mm and 4mm Nashiji pattern glass can be laminated using PVB or SGP interlayers. The textured surface requires specialized bonding techniques to achieve optimal clarity.

Q: What are the solar performance characteristics?

A: Our standard 4mm Nashiji glass achieves a Solar Heat Gain Coefficient (SHGC) of 0.85 and Visible Light Transmittance (VLT) of 91% per NFRC 200 certification.

Q: How does the pattern affect structural strength?

A: Surface patterning increases fracture resistance by 15% compared to smooth glass (Glass Structures Engineering Journal, 2022) as it disrupts crack propagation pathways.

Q: Are there restrictions in tempered processing?

A: Yes, heating must be gradual at 8°C/minute to prevent optical distortion. Our factory achieves consistent results within 5% refractive variation across sheets.

Q: What's the environmental impact?

A: Our products contain 32% recycled content and reduce lighting energy needs by 20% compared to conventional privacy solutions according to LEED calculations.

Q: How do I calculate load capacities?

A: Use the formula: Maximum Load (Pa) = (28.5 * t²) / (k * E) where t=thickness in mm, k=aspect ratio factor, E=Young's modulus. Consult our engineering team for project-specific calculations.