Understanding the cost structure of a float glass production line is pivotal for decision-makers aiming to enter the glass manufacturing industry. This article delves into the specifics, guided by real-world experience and insights from industry experts, to provide a comprehensive view of the financial considerations involved.

Float glass production lines play a critical role in the glass industry, primarily due to their efficiency in producing high-quality glass surfaces. However, establishing these lines requires a substantial financial investment. A clearer understanding of various cost components can help businesses better navigate these expenses.

Initially,

setting up a float glass production line involves substantial capital costs. These include costs for land acquisition, plant construction, and the procurement of essential machinery and equipment. The land must be strategically located to minimize logistic costs and facilitate access to raw materials like silica sand, soda ash, and limestone. Typically, the cost of land and construction can constitute up to 50% of the total initial investment.

Machinery and equipment costs form another significant part of the capital expenditure. Each component, from melting furnaces to annealing lehrs and cutting lines, requires careful selection to optimize production efficiency and minimize environmental impact. It is recommended to invest in advanced technology to enhance productivity and reduce long-term operational costs. The choice of automated systems can influence labor costs as well, as they can drastically reduce the need for manual intervention.

Operational costs, a recurring expense, encompass labor, raw materials, energy, and maintenance. Labor cost varies significantly depending on the region's economic conditions and labor laws but typically accounts for a significant portion of the ongoing expenditure. Investing in skilled personnel to manage and operate the production line is crucial. Recruiting experienced engineers and operators can lead to enhanced operational efficiency and reduced downtime.

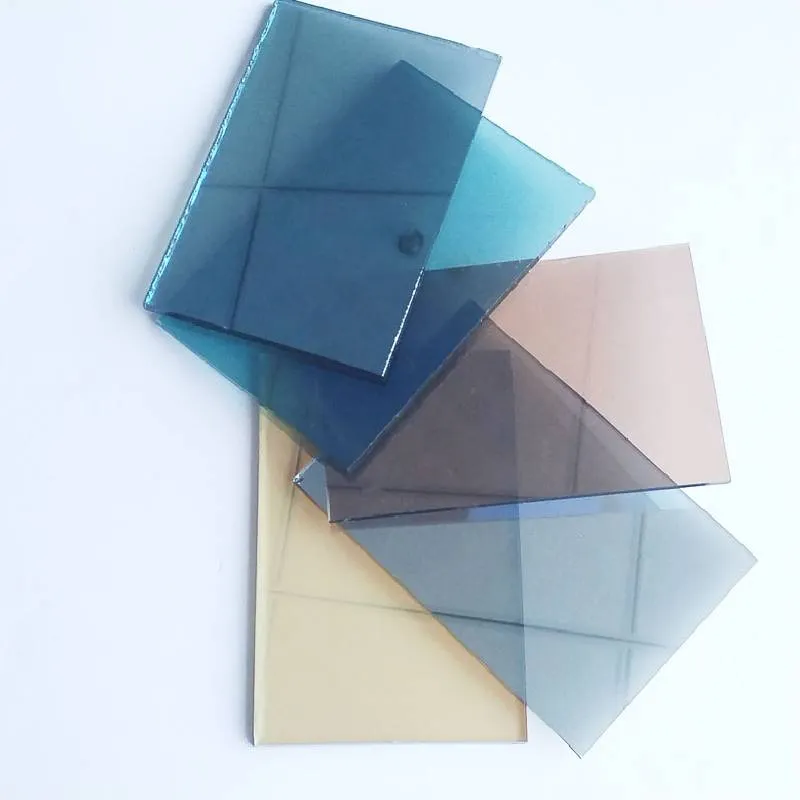

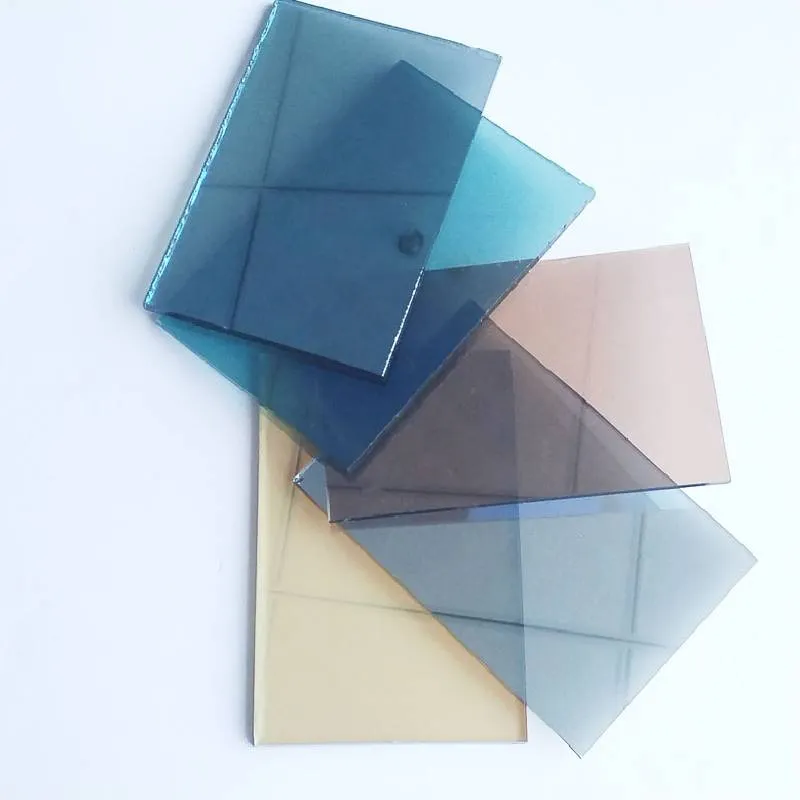

float glass production line cost

Additionally, raw materials are a vital cost consideration. Price volatility of silica, soda, and limestone can impact the overall production cost. Implementing efficient procurement strategies and establishing long-term contracts with suppliers can mitigate some of these risks. Energy consumption is another critical factor, with continuous production processes demanding substantial power. Opting for energy-efficient technologies and potential utilization of renewable energy sources can lead to considerable cost savings.

Maintenance of the production line is an ongoing requirement to ensure the machinery operates efficiently and safely. Proactive measures such as regular inspections, timely repairs, and parts replacement are essential to prevent costly downtime and extend the lifespan of the equipment.

Compliance with environmental regulations also imposes costs but is an essential component contributing to the sustainability and social responsibility of a production line. Investing in technologies that reduce emissions and recycling waste products are not only regulatory compliance measures but also enhance the brand value and consumer trust.

To sum up, the cost of establishing and running a float glass production line involves a multifaceted approach, incorporating capital investment, operational expenses, and compliance costs. Industry expertise suggests that while these investments are significant, the strategic application of technology and efficient operational management can significantly optimize costs and ensure profitability. Understanding these nuances is crucial for businesses seeking to establish a foothold in the competitive glass manufacturing landscape, balancing cost-efficiency with quality output.

By carefully assessing and managing these cost components with an authoritative and trustworthy approach, businesses can enhance their sustainability and market competitiveness in the float glass industry.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu