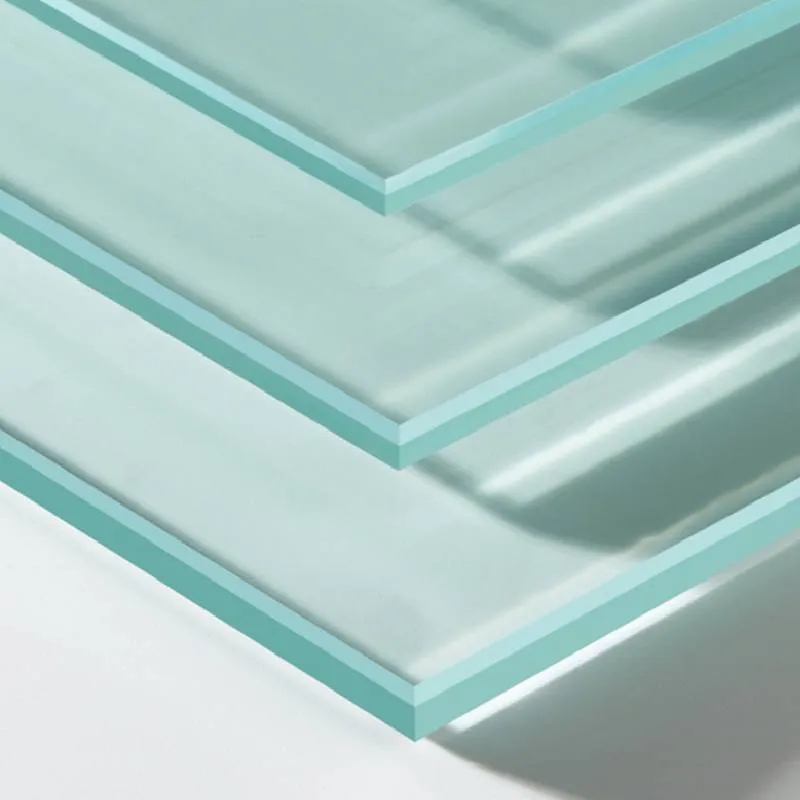

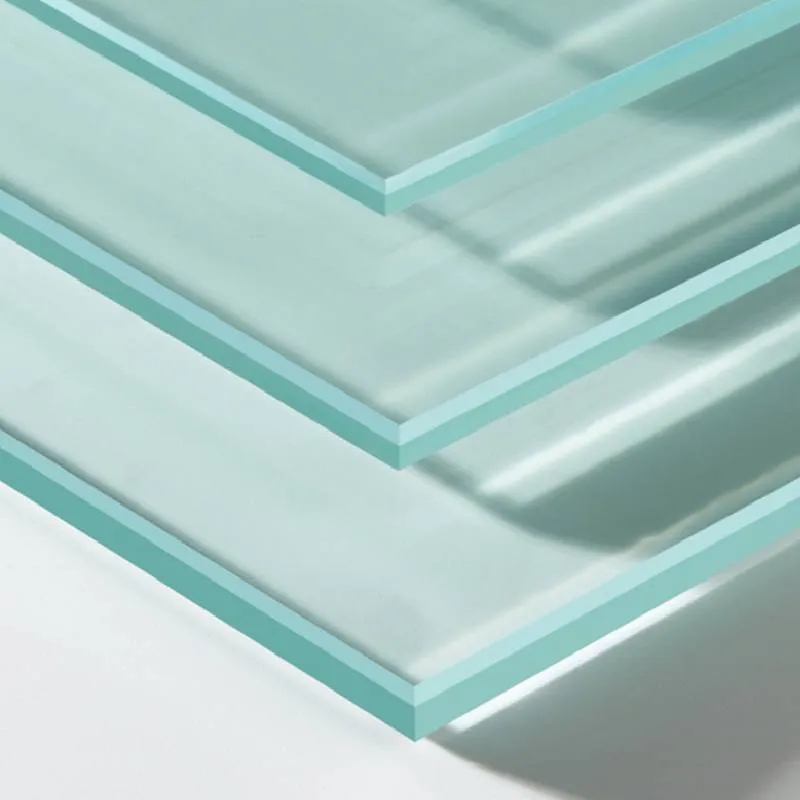

Float glass process is a revolutionary technique in the manufacture of high-quality, flat glass with a consistent thickness, offering exceptional clarity. An innovation traced back to the 1950s, this process has become the industry standard, essential for producing everything from windows to high-tech screens.

In practice, the float glass process begins with carefully selected raw materials sand, soda ash, limestone, and other minor additions. These components are melted at high temperatures in a furnace, forming a molten glass mixture. This mixture is then fed onto a bath of molten tin, which is perfectly smooth. Due to its higher density, the glass floats on the tin, forming a perfect,

flat surface.

One significant advantage of this method is the uniformity it ensures. The glass surface remains perfectly flat due to the natural leveling effect of the molten tin. The glass is then gradually cooled in an annealing lehr to prevent any internal stresses, thus ensuring durability. This precise temperature control confirms the reliability of the glass when subjected to external forces or environmental changes.

From an expertise perspective, the float glass process is remarkable not only for its efficiency but also for its versatility. It allows the production of glass at various thicknesses and can easily be adapted for additional treatments, such as coloring or coating, to enhance its functional properties, such as UV protection or shatter resistance. This flexibility in customization supports a wide range of industries, bolstering consumer products with enhanced features aligned with contemporary needs.

float glass process

Float glass demonstrates clear authoritativeness due to its widespread adoption in architectural and automotive applications. Notably, its role in the construction industry is unparalleled, providing the vital transparency needed in modern eco-friendly building designs, which focus on maximizing natural light to reduce energy consumption. The automotive industry also values float glass for its strength and optical clarity, which are critical for safety and design aesthetics.

Trustworthiness in the float glass process is ensured through rigorous quality control measures at each production stage. State-of-the-art diagnostic tools and strict adherence to international standards solidify the reliability of the final product. This commitment to quality is recognized by myriad certifications conferred upon production facilities globally. The trust placed in float glass by architects, engineers, and consumers attests to its significant role in today's infrastructure.

Considering the float glass process's experience, expertise, authoritativeness, and trustworthiness, its essential impact on product development and industry standards is evident. It is not only a testament to past innovation but continues to fuel advancements in glass technology, producing superior glass products that meet the demanding specifications of modern architecture and technology.

Thus, the float glass process remains at the forefront of the glass manufacturing industry, thanks to its combination of high efficiency, adaptability for innovation, and unwavering consistency in quality. It is an exemplary model of industrial ingenuity, with its foundational principles continuing to support and inspire future advancements in glassmaking.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu