Float glass, a predominant material in the construction and automotive industries, forms the basis of numerous applications due to its unique properties and manufacturing process. Known for its flat and smooth surface, float glass is created through a method invented by Sir Alastair Pilkington in the 1950s. This process involves floating molten glass on a bed of molten tin, allowing gravity and surface tension to craft a uniform thickness and an immaculate finish. This method revolutionized glass production, making float glass a cornerstone in various sectors.

With its versatility, float glass finds its usage ranging from architectural marquis features to the delicate precision required in high-end electronics. One of the defining characteristics of float glass is its clarity and devoid of distortions, an element essential for constructing edifices that encompass large glass windows and facades. These attributes not only enhance aesthetic appeal but also play a critical role in energy efficiency. When strategically installed, float glass can optimize natural light ingress, significantly reducing reliance on artificial lighting and aiding in heat regulation, contributing to a building's energy efficiency.

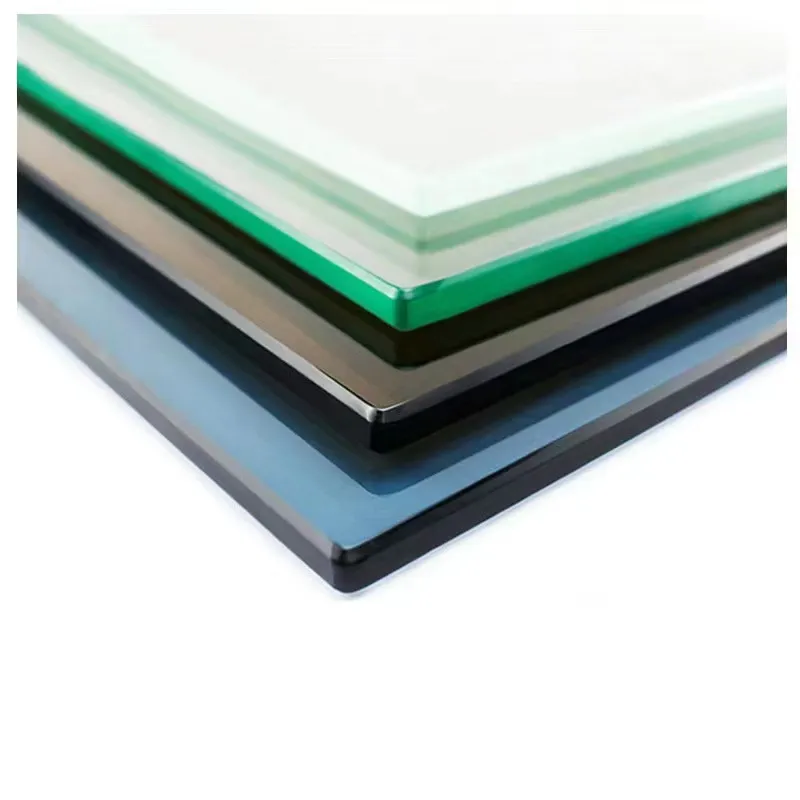

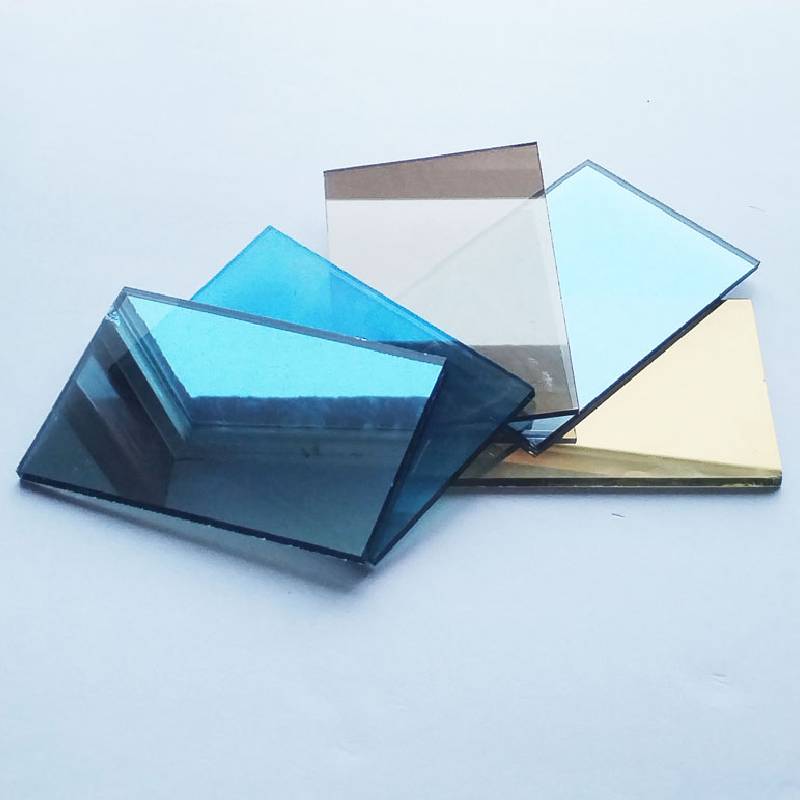

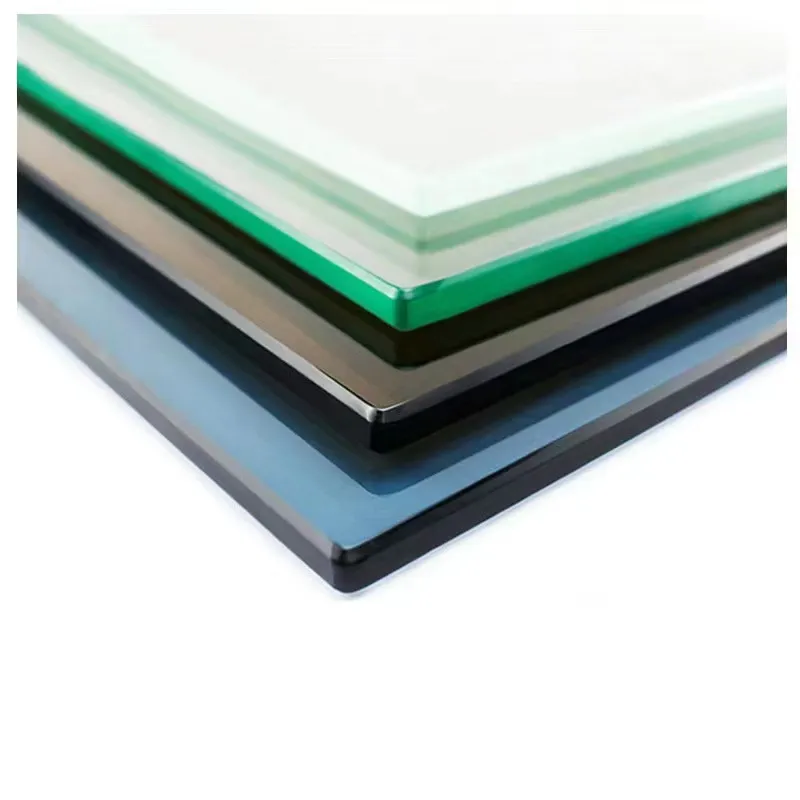

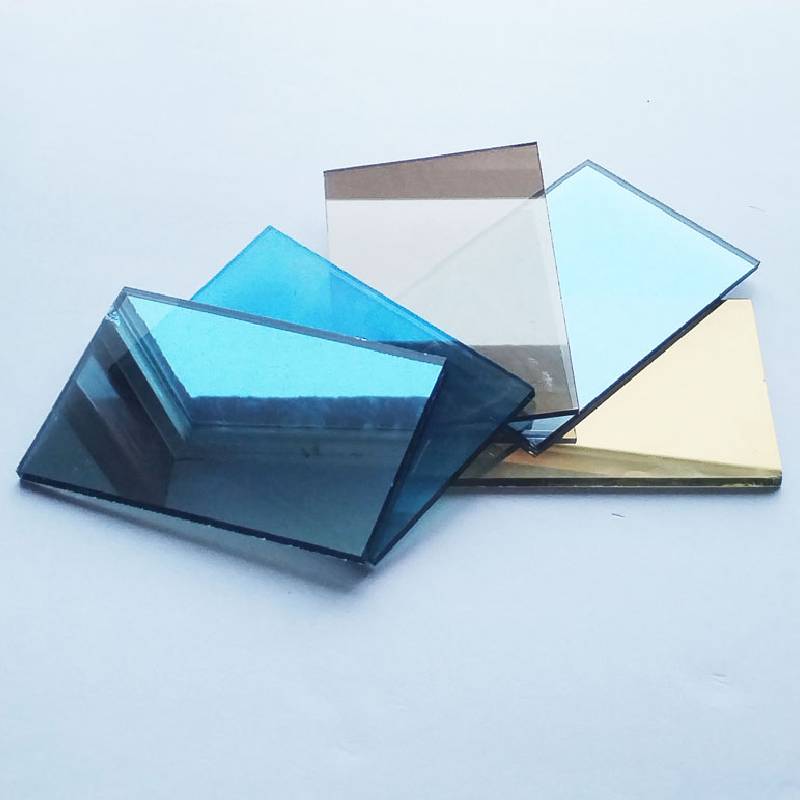

From a professional perspective, float glass offers distinctive expertise in customization to meet specific project requirements. It can be easily tempered, laminated, coated, or tinted, providing architects and designers with limitless possibilities. This flexibility ensures that buildings are not only visually appealing but also meet the highest safety and environmental standards. For instance, when float glass undergoes tempering, its strength is amplified, making it suitable for areas prone to high stress or extreme weather conditions, thus offering an added layer of security and durability.

In terms of authoritativeness, the consistent quality and performance of float glass have established it as a material of choice among industry leaders and construction professionals. Renowned companies around the globe continue to invest in advancements within the float glass sector, further enhancing its capabilities. These improvements include the development of low-emissivity coatings that improve insulation properties, effectively lowering heating and cooling costs, and ultra-clear glass that offers unparalleled transparency.

float glass meaning

The trustworthiness of float glass is backed by decades of rigorous testing and continuous innovation. For safety-conscious consumers, it assures compliance with stringent building codes and environmental regulations. Furthermore,

float glass plays a pivotal role in modern automotive design. Its ability to be molded into different shapes and sizes while maintaining optical clarity makes it indispensable in manufacturing windshields and other vital automobile components.

As sustainability becomes an ever-increasing priority, the recyclability of float glass supports ecological and economic objectives. The glass can be recycled indefinitely without losing quality, reducing carbon footprint and conserving raw materials. Companies are exploring ways to further enhance the efficiency of the recycling process, contributing to a circular economy within the glass industry.

In conclusion, float glass exemplifies a perfect blend of innovation and utility, meeting diverse demands across sectors through its adaptability and superior quality. Its contribution to the construction and automotive industries underscores its significance as an eco-friendly and robust material. Stakeholders, from architects and engineers to environmental advocates, recognize float glass as an integral component crafting the future of sustainable living and design, providing a symbiotic balance between tradition and modernity.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu