Float glass, also known as flat glass, plays a pivotal role in various industries, including construction, automotive, and solar energy. The process of producing float glass is both intricate and fascinating, requiring precision and expertise. This meticulous process not only ensures high-quality glass but also involves a range of innovative techniques that underscore the blend of science and art.

The journey of float glass production begins with the careful selection of raw materials, primarily sand, soda ash, and limestone. These components are essential for forming the glass batch. The preparation of these raw materials involves rigorous quality checks to ensure the final product meets the necessary quality and strength standards. The expertise required in determining the perfect ratios demonstrates the foundational skill in this endeavor.

Once the batch is ready, it undergoes melting in a large furnace at temperatures soaring above 1700°C. This step is critical as the extreme heat transforms the raw ingredients into molten glass. The control and management of this phase demand experience, given the need to maintain consistent temperature and composition throughout the melting process, preventing any flaws or inconsistencies in the glass.

The molten glass is then carefully poured onto a bed of molten tin in a controlled environment, a marvel of engineering that characterizes the float glass process. The glass floats on the tin, spreading out to form a smooth and even surface, a testament to the precision involved in this stage. The attention to detail and the artistry in controlling the thickness and width of the glass ensure a flawless output, showcasing industry expertise.

This floating phase is followed by controlled cooling, known as annealing, which is pivotal for relieving any internal stresses within the glass. This stage demands meticulous control and authoritative understanding of thermal dynamics to ensure that the glass does not crack or warp. Professionals in this domain leverage their deep knowledge to fine-tune this phase, which directly impacts the durability and quality of the glass.

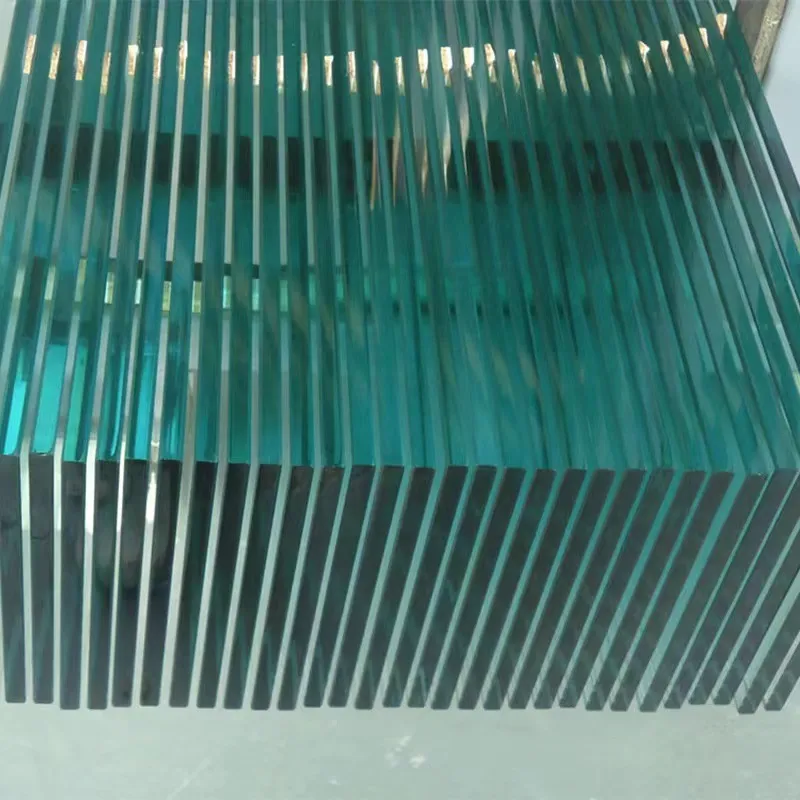

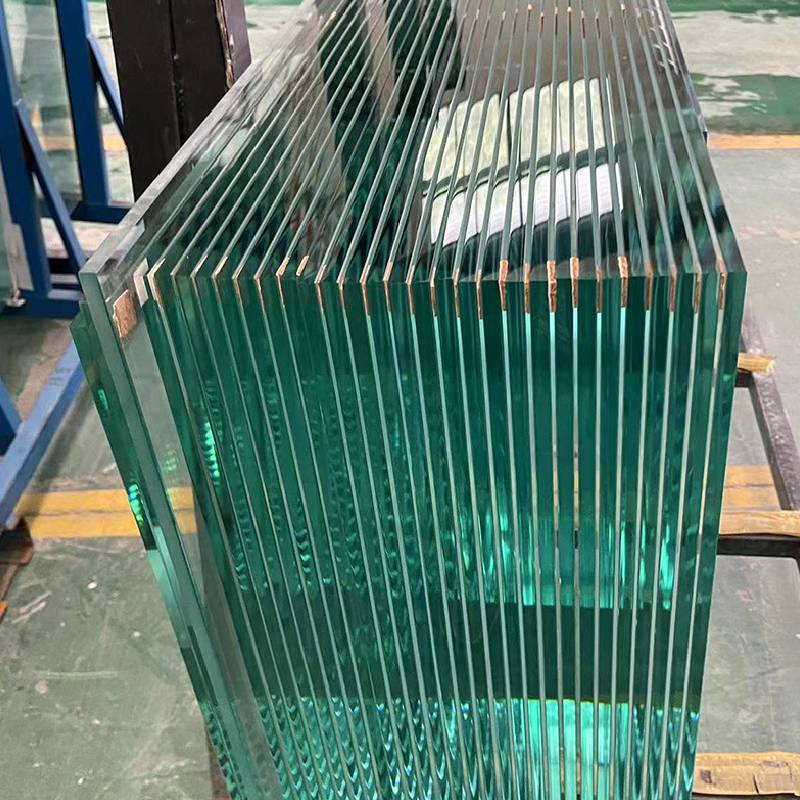

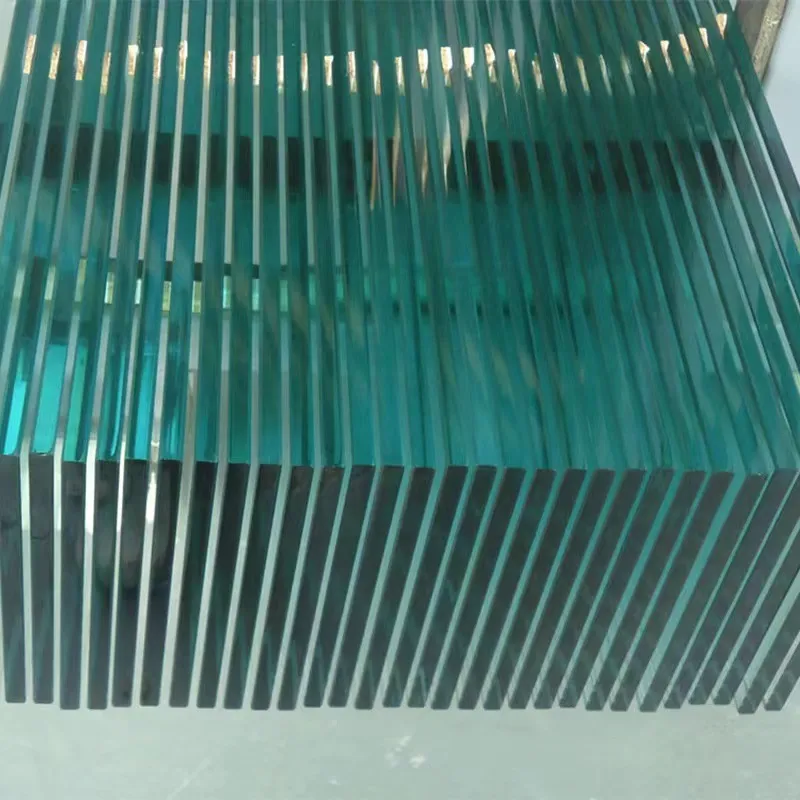

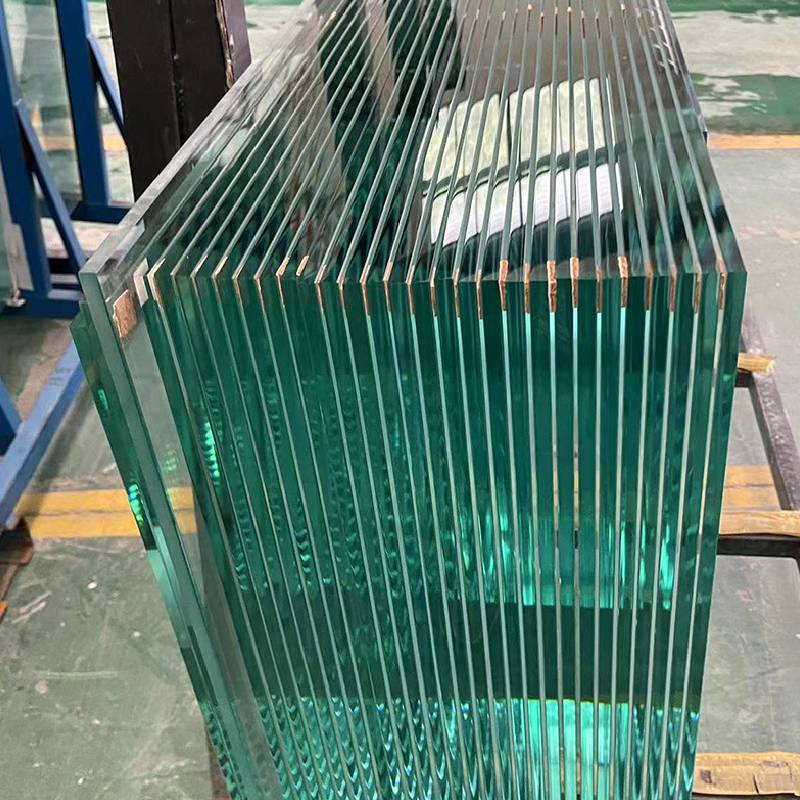

float glass production process

Safety and quality compliance are paramount throughout the float glass production process. Rigorous testing and quality assurance measures are in place to certify the glass meets industry standards. Trust is built through these protocols, emphasizing the reliability and credibility of the manufacturers involved in the process.

The expertise required in float glass production is further extended with additional processes such as cutting, coating, and tempering, depending on the specific applications of the glass. Each of these processes demands a tailored approach, highlighting the versatility and authoritative knowledge within the industry.

Finally, sustainability is becoming increasingly integral to the float glass production process. Innovations in energy efficiency and recycling of glass cullet in the manufacturing cycle not only reduce environmental impact but also demonstrate the industry’s commitment to sustainable practices. This evolution reflects an experience-driven shift towards greener production methods, aligning with global environmental goals.

In conclusion, the float glass production process is a sophisticated balance of expertise, experience, and authoritative knowledge. From raw material preparation to final product evaluation, each stage is meticulously managed to produce high-quality glass that meets diverse industrial needs. The dedication to quality, innovation, and sustainability positions the float glass manufacturing industry as both a leader and a trusted partner in modern industrial applications.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu