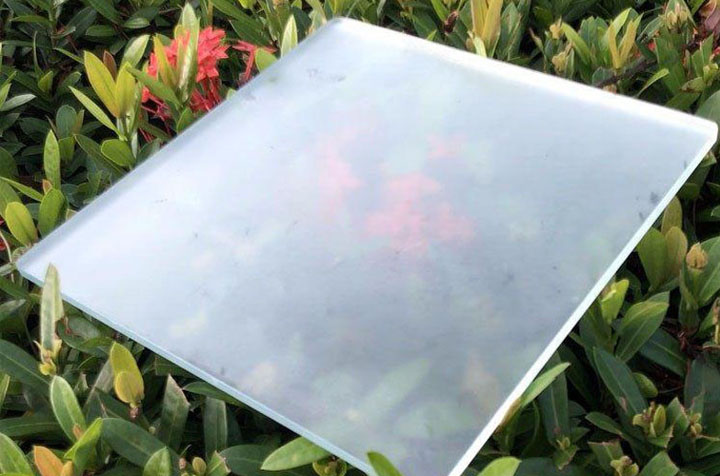

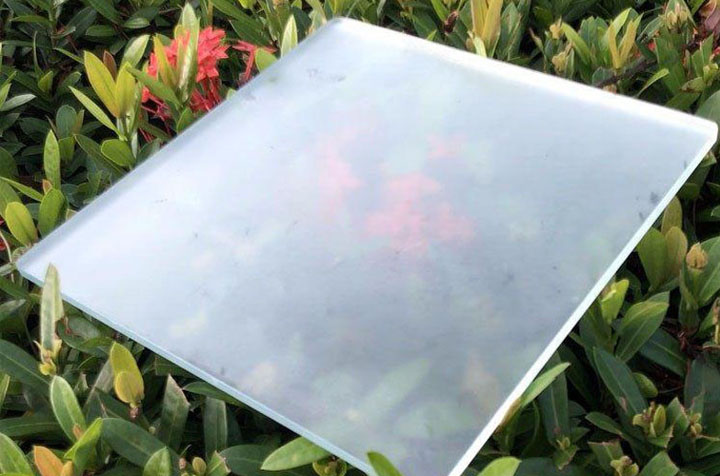

Float glass, a pivotal advancement in the glass manufacturing industry, offers a blend of functionality and aesthetic appeal. Through a sophisticated process involving floating molten glass on a bed of molten tin, float glass achieves exceptional smoothness and uniform thickness, which are crucial for diverse products ranging from architectural windows to automotive windshields.

In terms of professional expertise, understanding the technical nuances of float glass production is essential. The precision involved in controlling the temperature and atmosphere in the float bath ensures minimal defects and optimal clarity. This expertise extends to the quality control mechanisms employed, where advanced optical and laser technologies are used to detect and rectify any deviations in thickness or surface quality. This meticulous attention to detail assures that float glass meets stringent industry standards, affirming its reputation for high quality and reliability.

From an authoritative perspective, float glass sets the benchmark for modern glass applications. Its versatility is unmatched; it is often chosen for high-performance glazing systems due to its ability to be laminated, tempered, or coated to enhance thermal insulation or solar control. The authority of float glass in the market is further reinforced by compliance with various international safety and quality certifications, including ISO and EN standards, ensuring that it meets the diverse regulatory requirements for construction and automotive industries globally.

float glass

Gaining insight from real-world experiences highlights the trustworthiness of float glass as a product. Industry professionals often cite case studies where float glass installations have significantly improved energy efficiency in buildings, reduced UV exposure, and enhanced acoustic performance. Furthermore, widespread testimonials from engineers and architects underscore its durability and lifecycle value. These experiences consolidate float glass's status as a dependable choice for sustainable and functional building solutions.

When evaluating float glass from a trustworthiness standpoint, it's important to consider the environmental commitments of manufacturers. Many leading float glass producers have integrated sustainability into their production processes, reducing carbon emissions and recycling materials to minimize environmental impact. Such eco-friendly practices not only reflect a commitment to environmental stewardship but also build consumer trust in the brand's ethical standards.

In conclusion, float glass emerges as a product that encompasses a comprehensive set of attributes that meet the rigorous demands of modern applications. Its technical sophistication, industry authority, real-world effectiveness, and ethical production practices align it perfectly with the expectations of discerning consumers and professionals alike. Investing in float glass is not merely a functional choice but an affirmation of superior quality and conscientious manufacturing principles.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu