Innovative Float Glass Manufacturing Process

In the realm of industrial glass production, the float glass manufacturing process stands as a testament to modern engineering prowess. With roots deeply embedded in the mid-20th century, this technique revolutionized how glass is produced, setting a benchmark for quality and consistency. The manufacturing of float glass, a process that marries technology with intricate craftsmanship, remains an exemplary case of industry advancement, assuring superior flatness and structural integrity.

The journey of float glass begins with the careful selection and proportioning of raw materials including silica sand, soda ash, limestone, and other minor additives. These elements are mixed meticulously to form a batch, ensuring the requisite chemical composition necessary for superior glass qualities. Such rigorous precision underscores the industry's commitment to expertise and guarantees a product that consistently meets high-performance standards.

Once mixed, the batch is introduced into a furnace where temperatures soar above 1700 degrees Celsius. The transformative power of heat melts the raw ingredients into a molten state, a stage critical to determining the end product's attributes. This phase showcases the authoritative control over variables, and experienced operators monitor the process, ensuring the melt is homogeneous and free from inconsistencies, highlighting their formidable expertise.

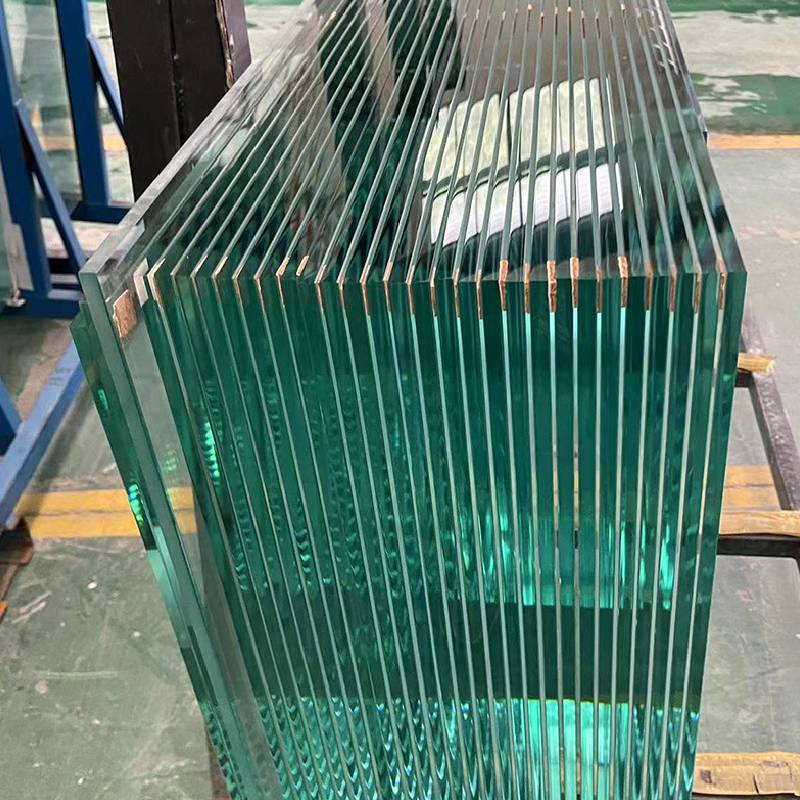

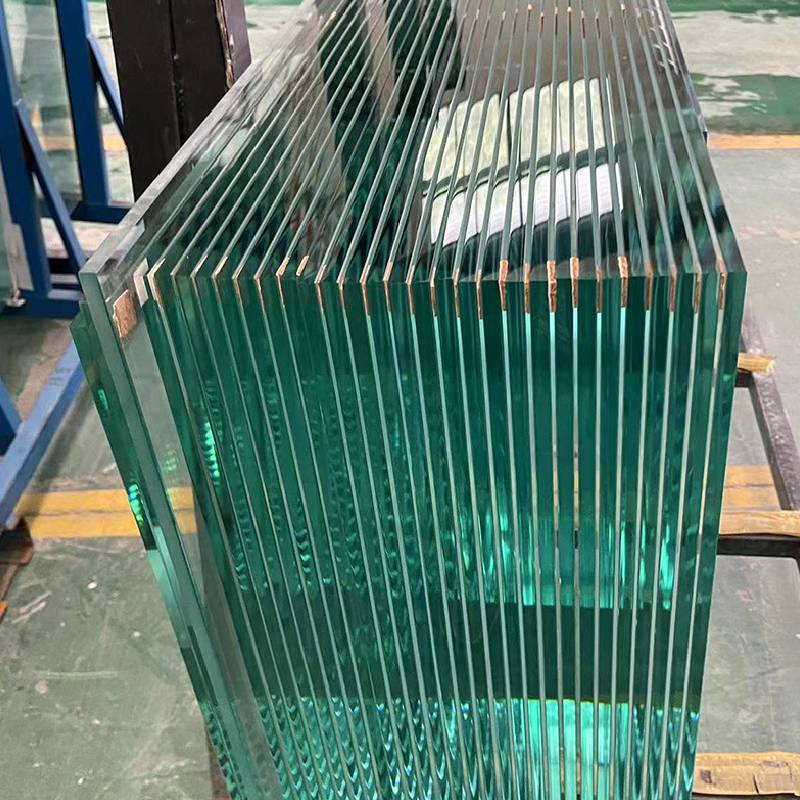

Emerging from the furnace, the molten glass descends onto a bath of molten tin — a distinctive feature of float glass production. This bath, maintained at precise temperature gradients, allows the glass to 'float' and spread uniformly. The unparalleled flatness and thickness uniformity achieved here demonstrate a mastery of technological control, a hallmark that sets high-quality float glass apart from its counterparts.

float glass making process

As the glass moves along the tin bath, it enters a controlled cooling zone known as the annealing lehr. This stage is characterized by gradual temperature reduction, an essential step to mitigate internal stresses and bolster the glass's structural reliability. The knowledge involved in managing this delicate balance further cements the process's authority and the high trustworthiness that industries place in float glass products.

Quality control is an integral aspect of the float glass manufacturing landscape. Continuous inspections ensure that each sheet meets rigorous international standards, enhancing the glass's credibility and reliability. Advanced technologies, such as automated scanning systems, identify imperfections that could compromise performance, reflecting the industry's commitment to quality and innovation.

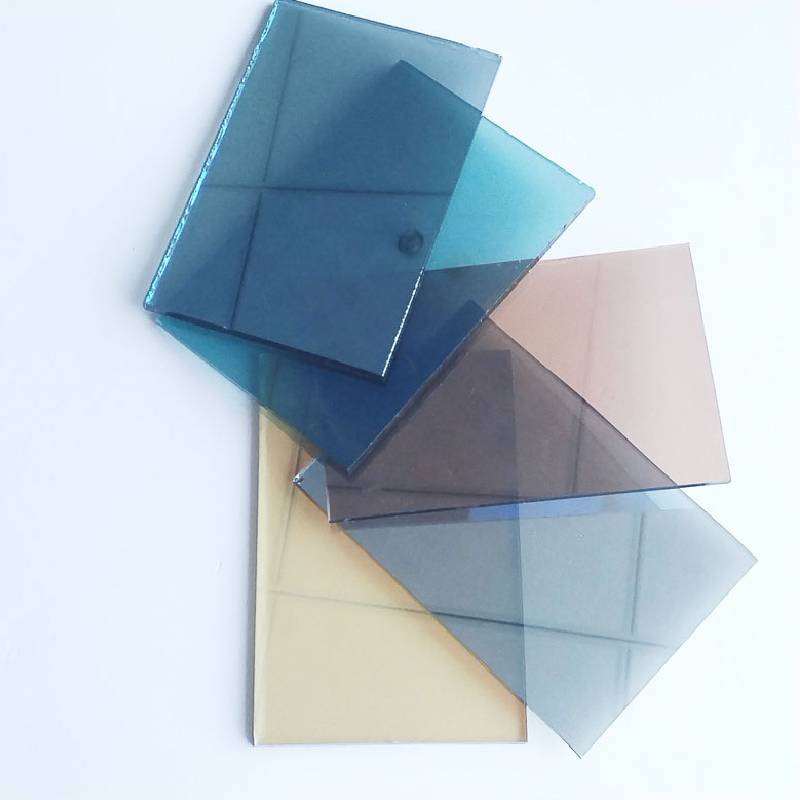

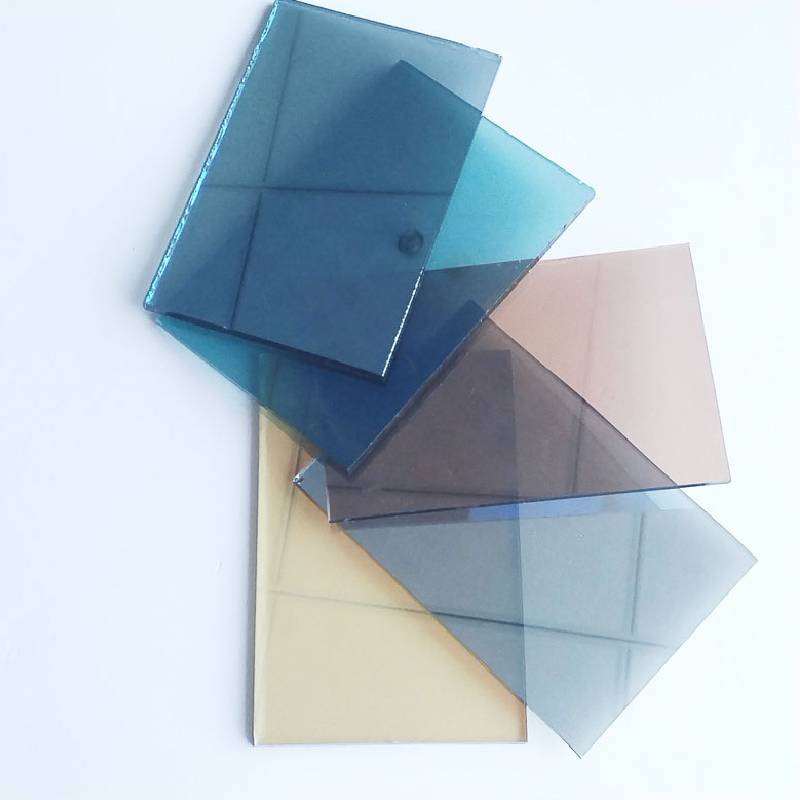

Float glass manufacturing culminates with cutting-edge techniques that prepare the glass for an array of applications. Whether destined for architectural marvels, automotive components, or high-tech displays, each piece operates under stringent guidelines to ensure unmatched clarity and durability. The adaptability of float glass across diverse sectors underscores its product superiority, exemplifying a trust in both process and material.

The evolution of the float glass process is a testament to the confluence of experience, expertise, and unwavering commitment to quality. It exemplifies how continuous innovation can redefine an industry, ensuring that float glass remains at the pinnacle of modern material science, trusted and revered across the globe.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu