Float glass manufacturing is a sophisticated process that combines cutting-edge technology with expert craftsmanship to produce high-quality glass for a variety of applications. At the heart of modern architecture and design, float glass serves as a fundamental material, exemplifying transparency, strength, and versatility. This article delves into the nuances of float glass manufacturing, underscoring its unparalleled expertise, authority, and trustworthiness in the industry.

The float glass manufacturing process begins with the precise selection and preparation of raw materials. Silica sand, limestone, dolomite, and soda ash are meticulously chosen for their purity and chemical properties. These ingredients are blended in specific proportions to ensure a consistent and homogenous mix, critical for producing float glass that meets stringent quality standards. The raw materials are fed into a furnace, where they are melted at temperatures exceeding 1700°C, transforming into a molten glass mixture.

One of the most remarkable aspects of float glass production is the float bath technique, a testament to the industry's expertise and innovation. The molten glass is carefully poured onto a bath of molten tin, where it spreads out to form a level sheet. Gravity and surface tension work in synergy to produce a perfectly flat surface, eliminating the need for mechanical polishing. This process imparts a unique smoothness and clarity to the glass, distinguishing float glass from other types.

As the glass cools, it undergoes a rigorous annealing process, which gradually reduces its temperature to relieve internal stresses. This step is paramount to enhancing the glass's mechanical strength and thermal stability, ensuring it can withstand various environmental conditions. The annealing process is highly controlled, drawing on decades of expertise to fine-tune parameters that guarantee the optimal balance between durability and flexibility.

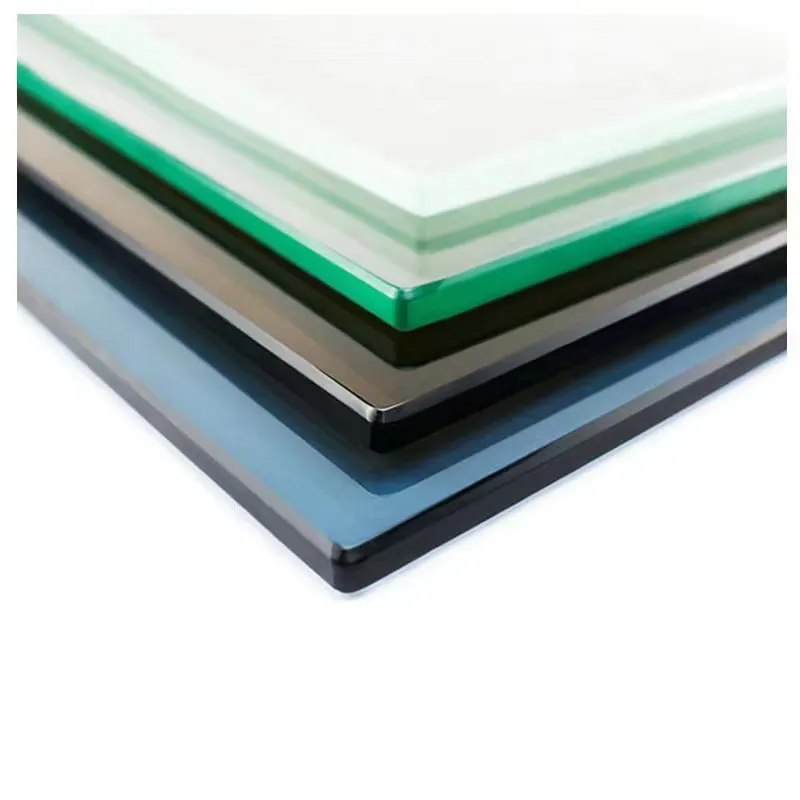

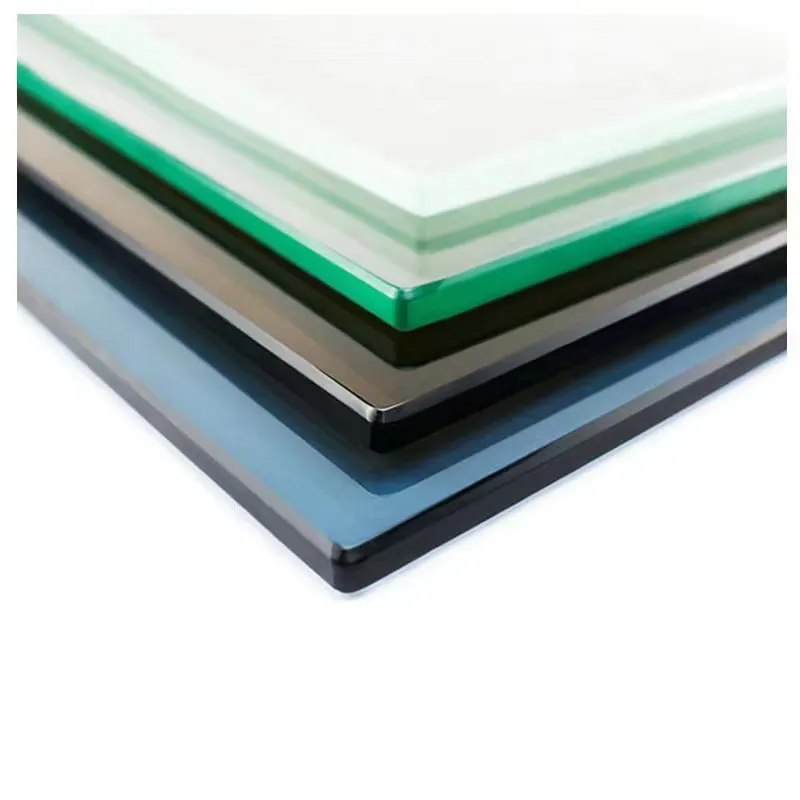

float glass manufacturing

Beyond technical precision, float glass manufacturing reflects a commitment to environmental sustainability and innovation. Modern plants utilize advanced furnace designs and state-of-the-art pollution control systems to minimize emissions and energy consumption. Recycled glass, or cullet, is often incorporated into the batch composition, reducing the need for virgin raw materials and contributing to a circular economy. These initiatives underscore the industry's dedication to producing eco-friendly products without compromising quality.

The versatility of float glass extends far beyond architectural applications. Its exceptional clarity and flatness make it ideal for automotive, electronic, and solar energy industries. In automotive applications, float glass is crafted into windshields and windows, offering safety and aerodynamics. The electronics sector relies on its transparency and uniformity for display technologies, while the solar energy industry values its effectiveness in photovoltaic panels, enhancing energy efficiency and performance.

Authoritativeness in float glass manufacturing is further reinforced by adherence to international quality standards and certifications. Manufacturers invest in comprehensive testing and quality assurance protocols, ensuring that every sheet of glass meets or exceeds industry benchmarks. Organizations such as the International Organization for Standardization (ISO) provide frameworks for consistent quality and continuous improvement, reinforcing consumer confidence and trustworthiness.

In conclusion, float glass manufacturing epitomizes a symbiotic relationship between tradition and innovation. Rooted in a legacy of craftsmanship and refined through contemporary advancements, this process yields a product that is indispensable in today's world. Its expertise and authority are evident in every stage of production, from material selection to finished product, embodying a commitment to excellence and sustainability. As demand for high-performance materials grows, float glass continues to be a cornerstone of progress, offering endless possibilities across industries and applications.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu