The float glass manufacturing process is a cornerstone of the modern glass industry, blending art with precision engineering to produce the flat glass sheets essential to numerous products and architectural designs. As a subject of expertise, understanding this complex yet fascinating procedure not only boosts industry knowledge but can also improve product innovation and quality assessment. Offering deep insights into this process, we explore both its technical accuracy and the tangible experiences of industry experts, ensuring comprehension and appreciation of its pivotal role.

Initially developed in the mid-20th century, the float glass method revolutionized glass production by providing a continuous and uniform thickness to glass sheets, qualities previously unattainable with older techniques. This innovation arose from the creative minds dedicated to problem-solving, leveraging a perfect synchronization between natural elements and engineering creativity.

At the heart of the float glass process lies a molten tin bath — a key component that defines its uniqueness. The process begins with raw materials such as silica sand, soda ash, and dolomite being carefully weighted and mixed before being melted together in a furnace reaching temperatures above 1,500 degrees Celsius (about 2,732 degrees Fahrenheit). This molten glass is then fed onto a bath of molten tin, where it floats like a liquid carpet, achieving unparalleled levels of smoothness and uniformity.

Our industry's experts comment that one of the most important aspects of controlling this step is maintaining the temperature balance. Shifts in atmospheric or material conditions can lead to variations affecting the thickness and quality, thereby necessitating constant precision in monitoring and adjustments. Automated systems often coupled with human oversight ensure the glass spreads to the correct thickness, ranging typically from 0.4 mm to over 25 mm, depending on the intended application.

Once the desired thickness and smoothness are achieved, the glass moves through the annealing lehr — a controlled cooling process crucial to reducing internal stresses. Annealing grants the glass the necessary strength, thus extending its durability and lifespan, an aspect our professionals stress as critical in quality control.

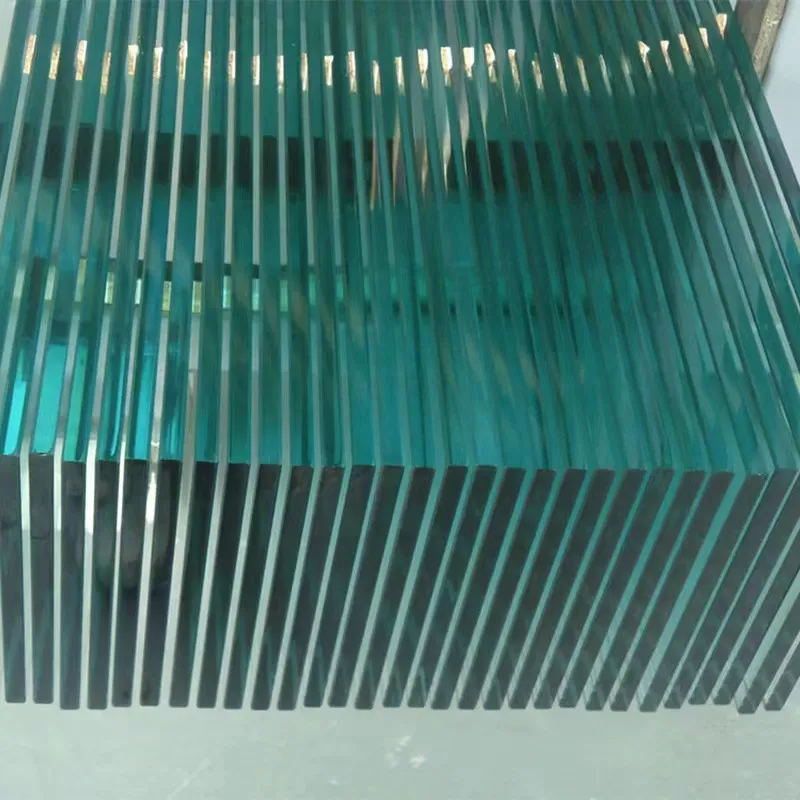

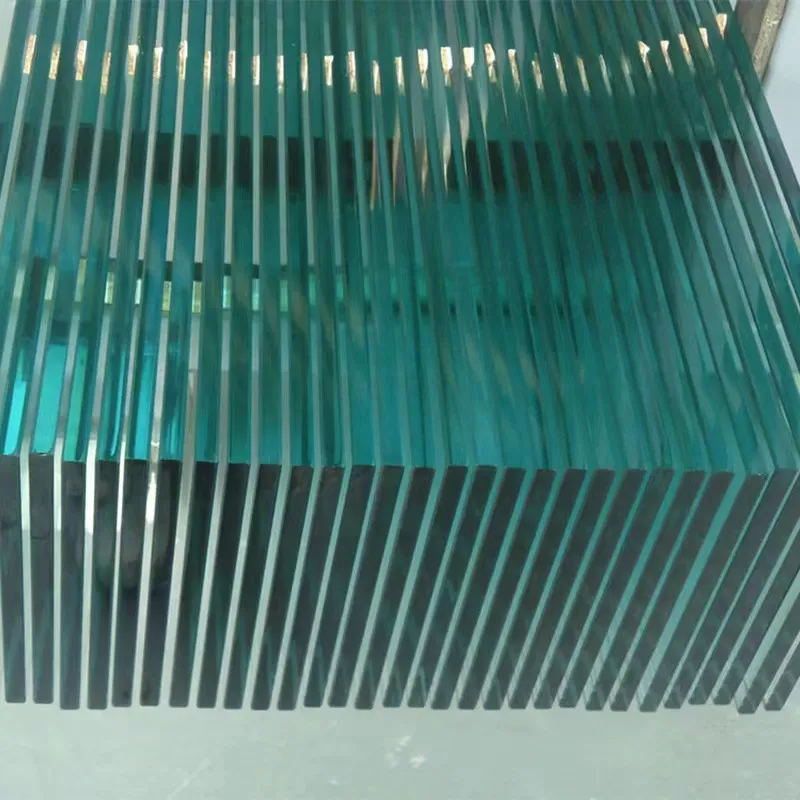

float glass manufacturing process

Industry veterans often underscore the importance of meticulous quality assessment post-productions, such as optical inspections, stress tests, and thermal endurance analyses. These steps confirm that each sheet of glass meets rigorous standards before it advances to cutting and further treatment phases like coating or lamination for specific aesthetic or functional requirements.

The sustainable impact of the float glass method cannot be understated. Today, advancements continue to evolve within the manufacturing landscape, as companies integrate eco-conscious practices. Using recyclable materials and investing in energy-efficient technologies, the float glass process aligns with global sustainability goals — reflecting a commitment not just to industrial advancement but to environmental responsibility as well.

Trust in the quality and consistency of float glass stems from the expert understanding and continual evolution of the manufacturing process. For those in related industries, mastering this process translates to enhanced product offerings—from everyday windows to sophisticated architectural features. The expertise accumulated over decades not only inspires future innovations but also assures that each piece of glass produced is not only fit-for-purpose but exemplary in quality, offering an authoritative standard by which all future productions can be measured.

The blend of science and artistry within the float glass manufacturing process represents a triumph of human ingenuity, its sophisticated elegance acknowledged by all who appreciate both its functionality and form. As industry necessities and consumer demands evolve, so too does this essential process, guided by experts who remain at the forefront of technological advancements, continually re-defining possibilities in glass craftsmanship.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu