Float glass manufacturing is a fascinating convergence of precision engineering and innovative materials science, resulting in a product that is integral to modern architecture and numerous industrial applications. This meticulous process involves a complex interplay of heat, chemistry, and physics, and demands a high level of expertise to ensure quality and efficiency.

At its core, float glass manufacturing is renowned for producing perfectly flat and uniform glass sheets. This is achieved by floating molten glass on a bed of molten tin, leveraging the natural tendency of liquids to find their own level. The process begins with raw materials like silica sand, soda ash, and limestone, which are carefully measured and mixed. These ingredients are then fed into a furnace that operates at temperatures exceeding 1,600 degrees Celsius. It is here that the raw components meld into a molten glass mixture.

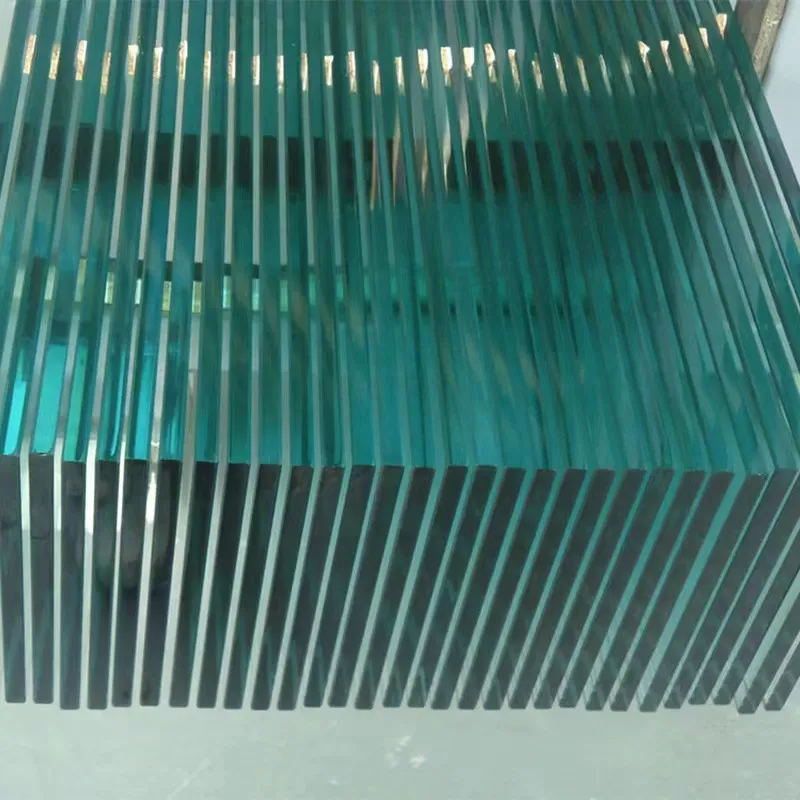

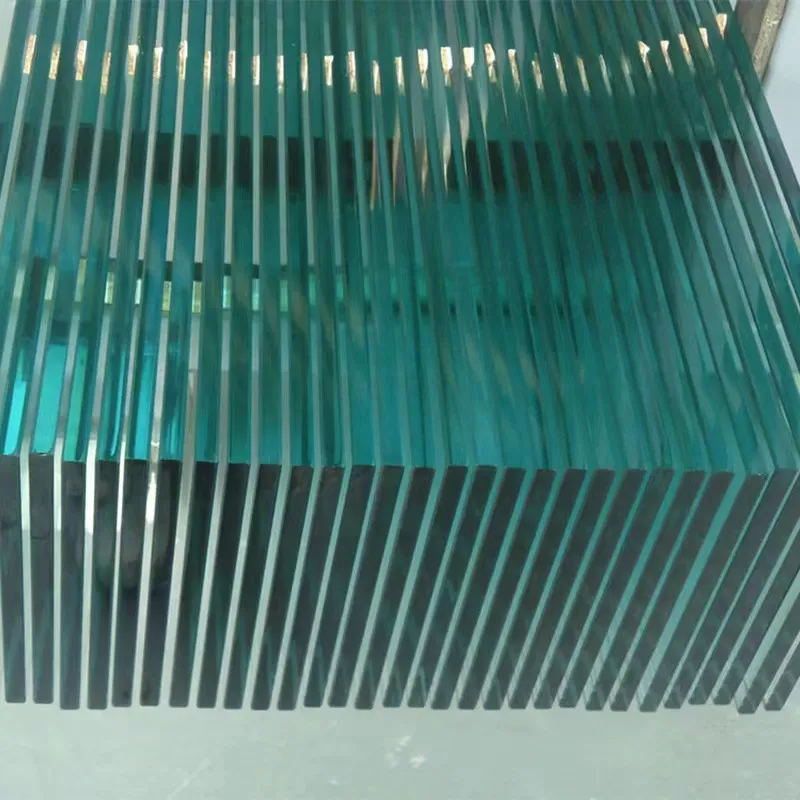

The next stage sees this molten glass pouring onto a bath of molten tin. Here, the glass spreads out in a uniform layer due to gravity and surface tension, resulting in unparalleled smoothness and uniform thickness. This precision is crucial, particularly for applications requiring flawless transparency and strength, such as in automotive, construction, and high-tech industries.

A key aspect of successful float glass production is the control of the furnace environment. Manufacturers must maintain exact temperatures and precise chemical balances to prevent imperfections like bubbles or inclusions, which could compromise the glass’s optical qualities. Advanced computer systems and skilled technicians constantly monitor these conditions, employing expertise and experience to adapt swiftly to any variables.

Beyond technical prowess, the sustainability of the float glass process is gaining attention. Modern innovations strive to reduce energy consumption and emissions, aligning with global environmental standards. For instance, recycling cullet (waste glass) back into the production process not only lessens raw material usage but also reduces the energy required for melting. Companies adopting such green practices enhance their authority and build trust with environmentally-conscious consumers.

float glass manufacturing

Safety and reliability are non-negotiable in float glass manufacturing. Compliance with international quality standards such as ISO 9001 ensures processes meet stringent quality and management requirements. This commitment to excellence builds trust with consumers and partners, reinforcing the manufacturer’s reputation as a dependable provider of high-grade glass products.

Customization is another significant trend in the float glass industry. Beyond standard sheets, manufacturers offer bespoke solutions tailored to specific client needs, such as incorporating coatings that enhance thermal insulation or UV resistance. This adaptability highlights a deep understanding and expertise in material science, further positioning these companies as authoritative figures in the glass manufacturing sector.

As the demand for innovative glass solutions continues to grow, the role of experienced and knowledgeable professionals in the float glass industry becomes even more critical. Their ability to blend traditional methods with cutting-edge technology ensures that the industry not only meets current market needs but also anticipates future trends and challenges.

In summary, float glass manufacturing is a sophisticated and nuanced process, requiring a blend of expert knowledge, cutting-edge technology, and a commitment to quality and sustainability. This dedication not only ensures the production of high-standard glass but also solidifies the position of manufacturers as leaders in a competitive, ever-evolving industry.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu