Float glass manufacturing is a fascinating process that revolutionized the production of quality glass, providing the world with crystal-clear and smooth surfaces for various applications. This expertise-rich method is rooted in the floating of molten glass on a bed of molten tin, a technique that ensures uniform thickness and flawless surfaces—a hallmark of modern engineering and design.

The journey of float glass begins with precise raw material selection. Sand, soda ash, limestone, and dolomite are meticulously chosen and combined in specific ratios to form batch compositions. The proportioning of these materials is crucial, as it impacts the chemical and physical properties of the final product. Each batch is subjected to high-temperature treatment in a glass furnace exceeding 1,700°C, transforming the raw materials into a molten glass mixture.

Expertise in controlling the furnace conditions plays a pivotal role in the manufacturing process. The molten glass flows from the furnace onto the surface of molten tin in a carefully controlled chamber. This particular setup allows for the glass to spread across the tin surface, forming a perfectly flat ribbon. The float process provides an unparalleled level of thickness control and surface quality, unmatched by previous glassmaking techniques.

Authoritativeness comes into play with precise temperature regulation within the float chamber, ranging from 1,100°C to 600°C along its length. A gradual cooling, or annealing process, ensures that the glass does not develop stress points, which would compromise its structural integrity. This step is crucial for producing glass that can withstand various environmental factors without deforming or breaking.

The float glass ribbon continuously moves along the pool of molten tin and eventually reaches the “lehr,” a system that cools the glass incrementally. The annealing process in the lehr is crucial for evenly distributing internal stresses, which prevents warping and enhances the glass's durability. As the glass exits the float chamber, it’s subjected to rigorous quality control measures. Automated systems equipped with laser technology detect and eliminate imperfections such as bubbles or inclusions, ensuring that only glass that meets stringent standards gets through.

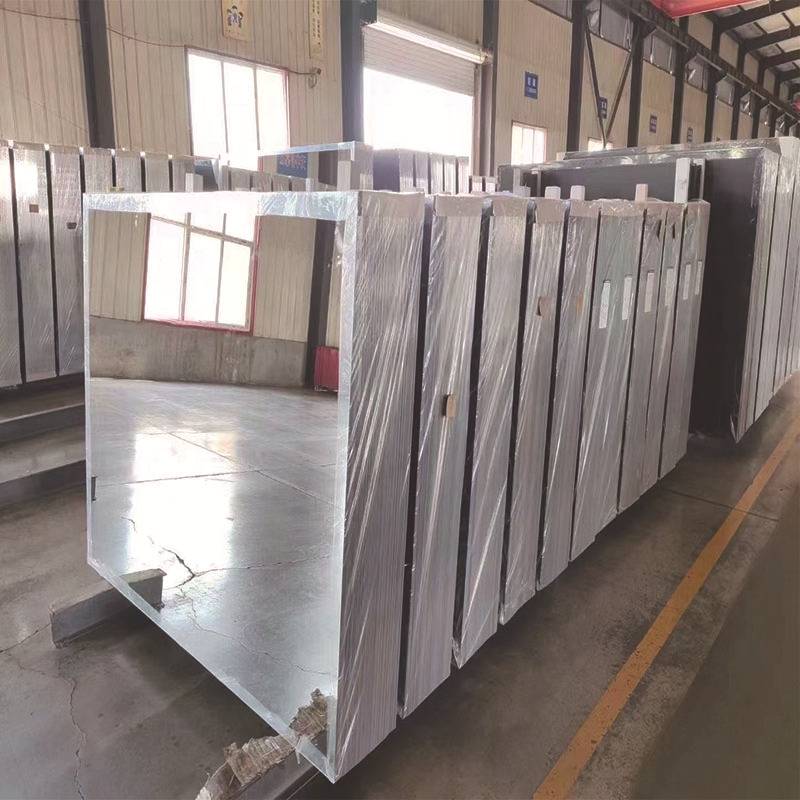

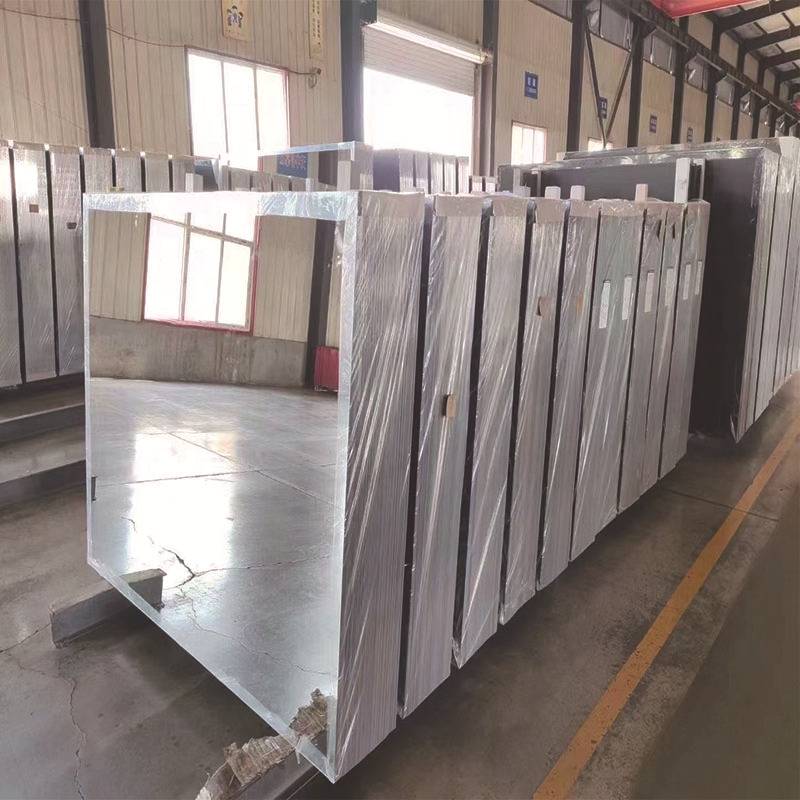

float glass manufacturing process

Trustworthiness in float glass manufacturing is bolstered by adherence to international standards and certifications. Manufacturers must conform to ISO standards, ensuring that glass produced is safe, reliable, and fit for purpose in diverse applications ranging from construction to automotive industries. These certifications build consumer confidence in products crafted from float glass, reinforcing its reputation as a premium material.

Furthermore, sustainability practices are increasingly playing a pivotal role in the float glass manufacturing process. Modern facilities incorporate recycling strategies for cullet (waste glass), which reduces the need for raw materials and energy consumption. This eco-friendly approach not only improves the cost-efficiency of glass production but also positions float glass manufacturers as responsible environmental stewards.

Combining decades of industry expertise with innovative advancements, float glass manufacturing continues to set the standard for top-quality glass products worldwide. From the architects who design skyscrapers to the engineers crafting automotive windshields, the reliability and excellence of float glass are trusted implicitly, underscoring the enduring importance of this advanced manufacturing process in our modern world.

Elevating both safety and design, float glass is more than a product—it's an embodiment of craftsmanship, precision, and technological prowess, ensuring its pivotal role in our daily lives and future endeavors.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu