Float glass manufacturing stands as a monumental advancement in the glass industry, offering unparalleled quality and versatility for diverse applications. With decades of proven expertise, float glass technology has become synonymous with strength, clarity, and precision, meeting the rigorous demands of modern architecture, automotive industries, and even high-tech devices.

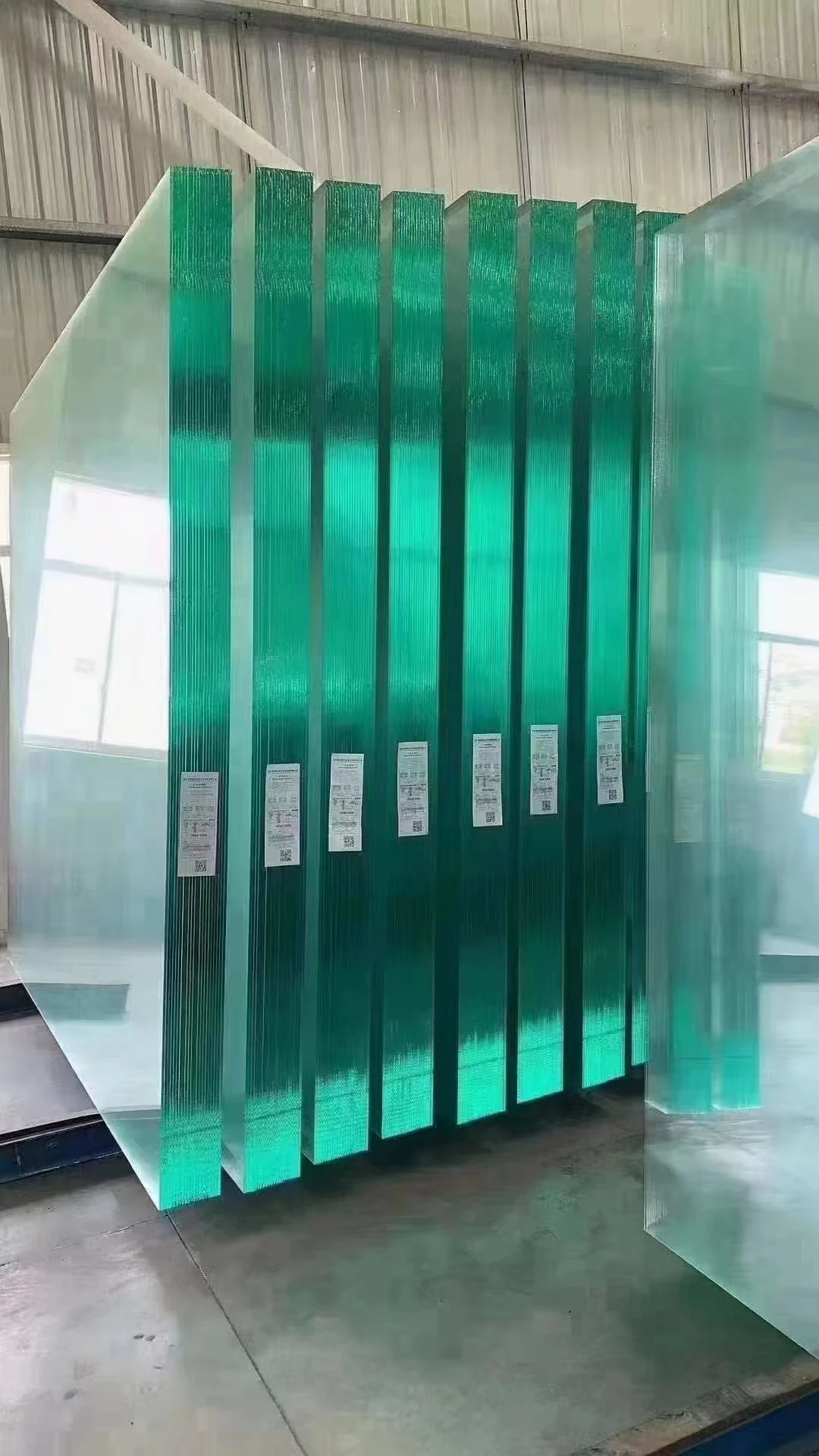

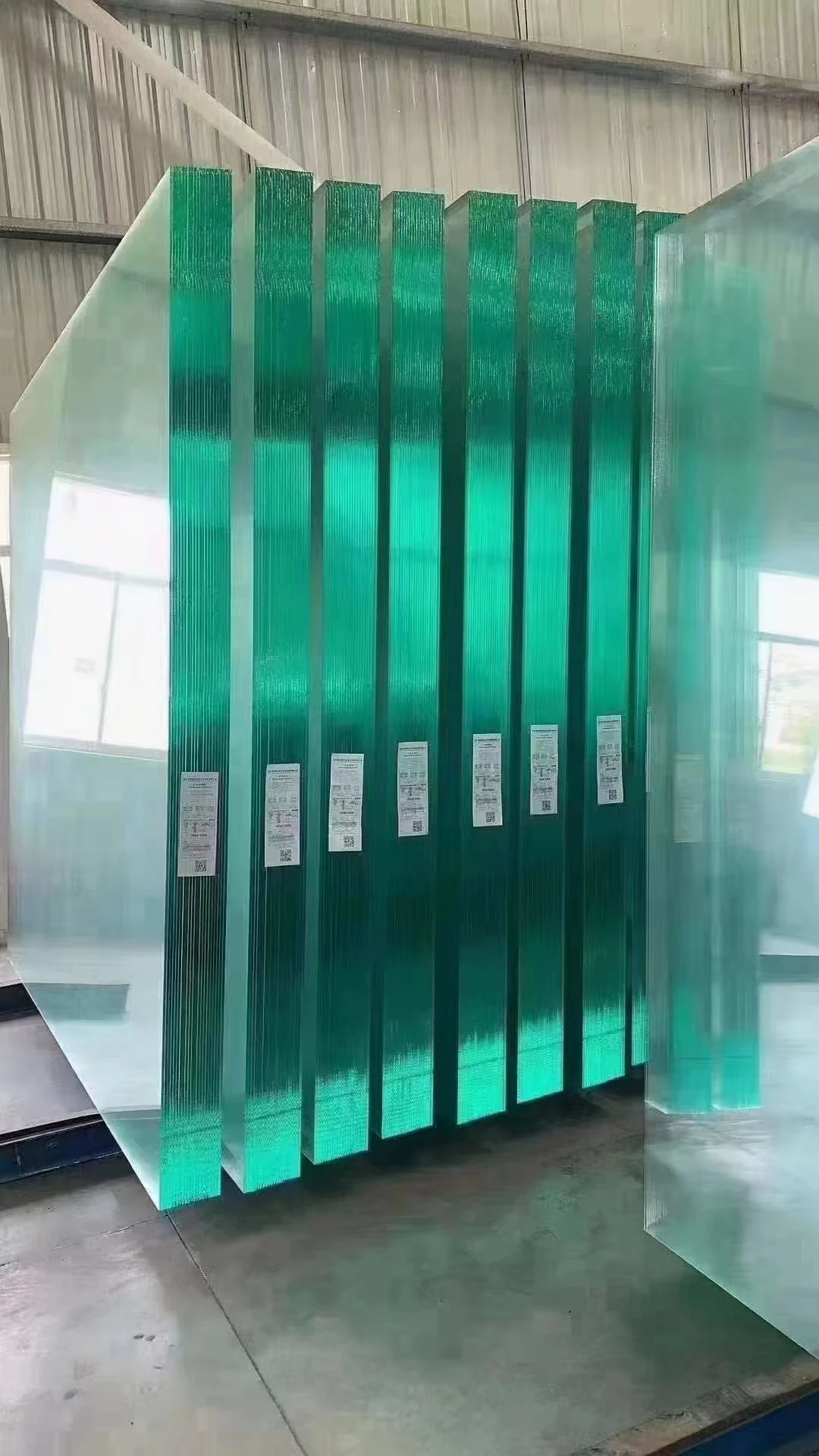

At the foundation of float glass manufacturing is the innovative float process, first commercialized by Sir Alastair Pilkington in the 1950s. This method revolutionized glass production, ushering in a new era of affordability and accessibility. The process starts with a carefully formulated mix of raw materials – mainly silica sand, soda ash, and limestone – which are melted in a furnace at temperatures exceeding 1700°C. The molten glass is then carefully floated onto a bath of molten tin under controlled atmospheric conditions. This unique feature of the float process ensures that both sides of the glass sheet remain flat and parallel, with a brilliantly smooth surface.

The strategic control of temperature and chemistry during this stage is critical, requiring in-depth expertise and experience from skilled operators. It involves understanding minute details such as the viscosity of the molten glass and the tin bath's cleanliness, achieving a consistent product free from distortions and imperfections.

Serving as a testament to its versatility, float glass finds use across an array of products. Architects value it for its transparency and structural integrity, ideal for modern minimalist designs involving large windows and glass facades. The automotive industry relies on its durability and optical clarity, ensuring safety without compromising visibility. Even technological innovations, like touchscreens and solar panels, benefit immensely from the robustness and precision of float glass.

float glass manufacturing

The authority of float glass manufacturers is further reinforced by compliance with international standards and regulations. Leading companies invest in research and development to push the boundaries of innovation, focusing on areas like energy efficiency and environmental sustainability. Newer technologies are exploring the integration of self-cleaning, low-emissivity, and tinted glass options, aligning with global trends toward eco-friendly buildings and energy conservation.

Trust in float glass products is built on a foundation of rigorous testing and certification. Top manufacturers conduct comprehensive quality control measures, such as stress tests and optical assessments, to ensure products meet high safety standards. They maintain transparency through detailed product documentation and certifications that verify performance metrics, bolstering client confidence in their products' safety and reliability.

In summation, float glass manufacturing represents a blend of history, innovation, and expertise. Its sophistication lies not only in the technicalities of the production process but also in the visionary applications it supports across industries. This industry continues to inspire trust and awe, promising a future brimming with possibilities. Whether for crafting the skyline-defining skyscrapers or the technology-driven gadgets of tomorrow, float glass remains an indispensable resource.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu