The realm of float glass is a fascinating domain within the broader glass manufacturing industry. Known for its exceptional quality and clarity, float glass has become an integral component in numerous applications, from architectural structures to automotive parts. As someone deeply embedded in the exploration of materials that constitute the backbone of modern construction and design, gaining a comprehensive understanding of float glass can be both enlightening and beneficial.

Float glass is produced through a method that involves floating molten glass on a bed of molten tin. This innovative process, developed in the 1950s, revolutionized the way we perceive glass due to its ability to create glass sheets of uniform thickness and superior smoothness. The process begins with raw materials such as silica sand, soda ash, dolomite, limestone, and other additives, which are combined and heated to an extremely high temperature to form molten glass. This molten glass is then fed into a float bath where it spreads and floats on the surface of molten tin. The unique aspect of this technique is the natural flatness and evenness achieved, allowing for distortion-free glass.

Encompassing the fields of architecture and automobile manufacturing, float glass is prized for its optical clarity and versatility. Architects appreciate its role in modern design; skyscrapers with large glass facades are made possible primarily through the use of high-strength float glass. Moreover, in residential settings, float glass stands as a staple in windows, glass doors, and interior design elements, offering a clean and unobtrusive look that enhances natural light transmission and energy efficiency.

From an automotive perspective, float glass is essential in the production of windshields and windows. The consistent thickness and structural integrity provided by float glass ensure safety and performance in vehicles. Automakers continually rely on the properties of this material to improve aerodynamics, reduce weight, and enhance the aesthetic appeal of modern cars.

float glass meaning

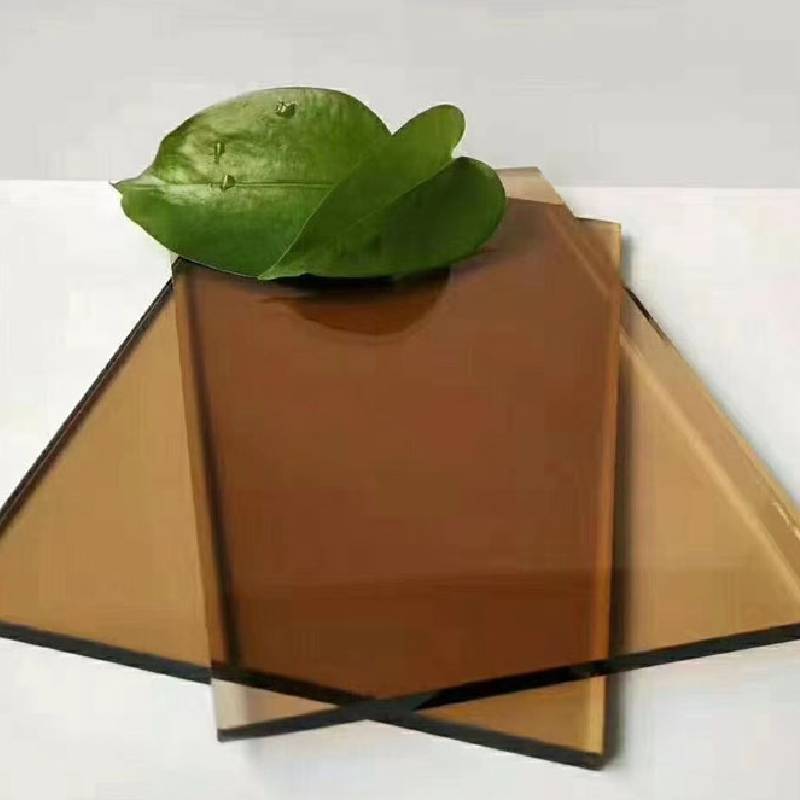

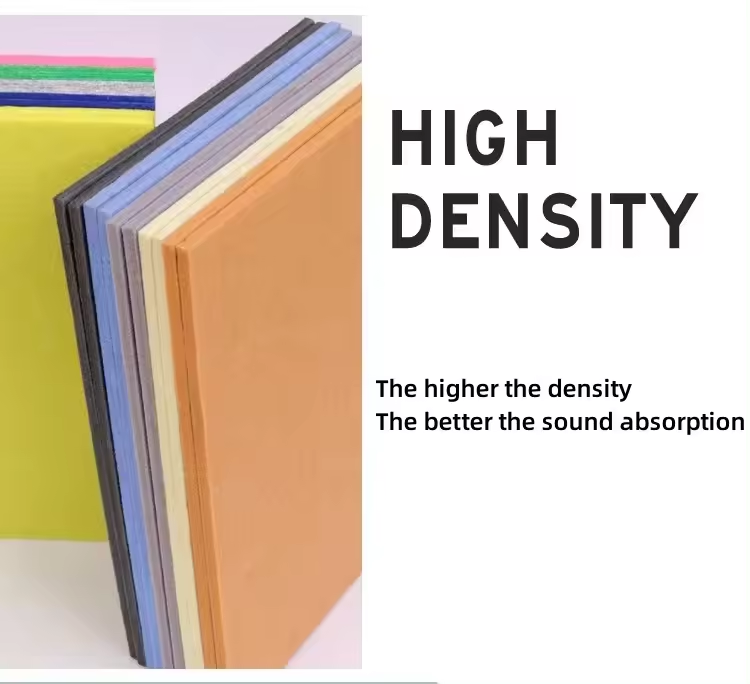

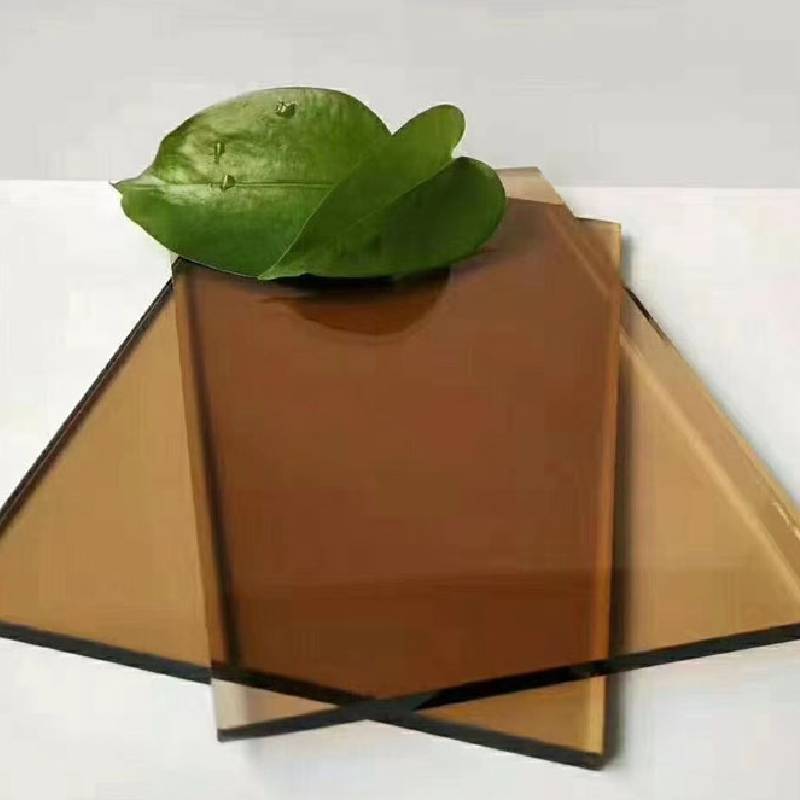

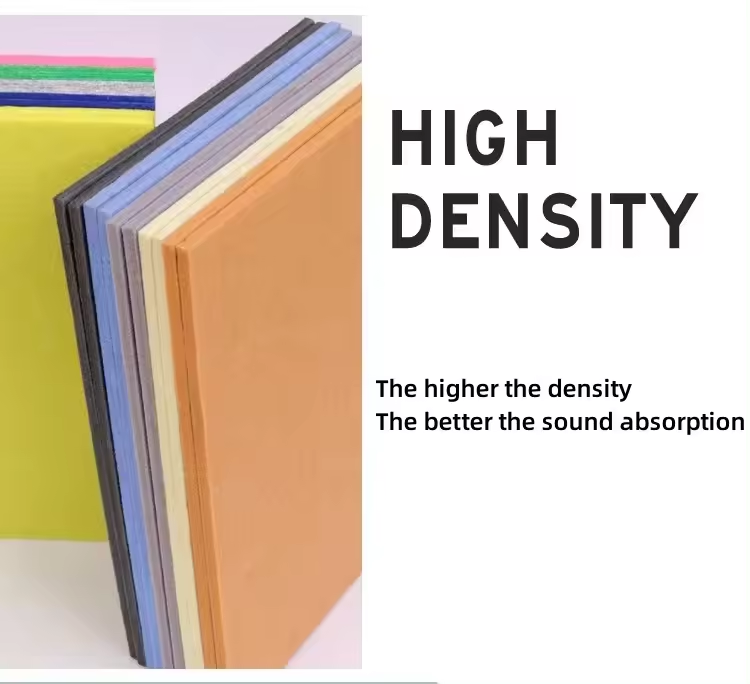

Moreover, float glass is often subjected to further processing to enhance its properties, such as tempering, lamination, or coating. These additional treatments confer increased strength, added safety features, and improved thermal or acoustic insulation. Tempered glass, for example, undergoes a rapid heating and cooling process that increases its strength and safety, making it ideal for use in situations where human impact might occur.

In terms of sustainability, float glass production has made strides towards minimizing environmental impact. Technological advancements have allowed manufacturers to reduce energy consumption and emissions during the glass production process. Additionally, glass itself is a recyclable material, and initiatives towards recycling waste glass from float glass production into new products are becoming more prevalent. This aligns with the growing demand for sustainable building materials and eco-friendly manufacturing practices.

For businesses in the glass industry, understanding and harnessing the potential of float glass is critical. This means keeping abreast of technological advancements in production techniques, as well as trends in design and consumer preferences. There is also a responsibility to maintain high standards of quality control and to ensure safety and durability across all applications.

In conclusion, float glass represents a pinnacle of innovation within the glass manufacturing industry — it combines simplicity in its production with complexity in its application. Whether it is enhancing the aesthetic of modern architectural marvels, ensuring safety and clarity in automotive applications, or adapting to sustainability demands, float glass continues to establish itself as a vital component across multiple sectors. As the industry continues to push the boundaries of what can be achieved with this remarkable material, the significance of float glass will only continue to grow.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu