Float glass process revolutionized the glass manufacturing industry by offering unparalleled consistency and quality, capturing the essence of efficiency and precision. This innovative method not only dominates the market but also sets a high standard, solidifying its place as the backbone of modern glass production.

Glass is a staple material used across various industries, from automotive to architecture. Its transparency and versatility make it indispensable. Yet, achieving uniform thickness and a flawless finish was a challenge before the advent of the float glass process. Henry Bessemer, a pioneer in engineering, laid the groundwork of this process; however, it was perfected by Sir Alastair Pilkington in the 1950s, marking a new era in glass making.

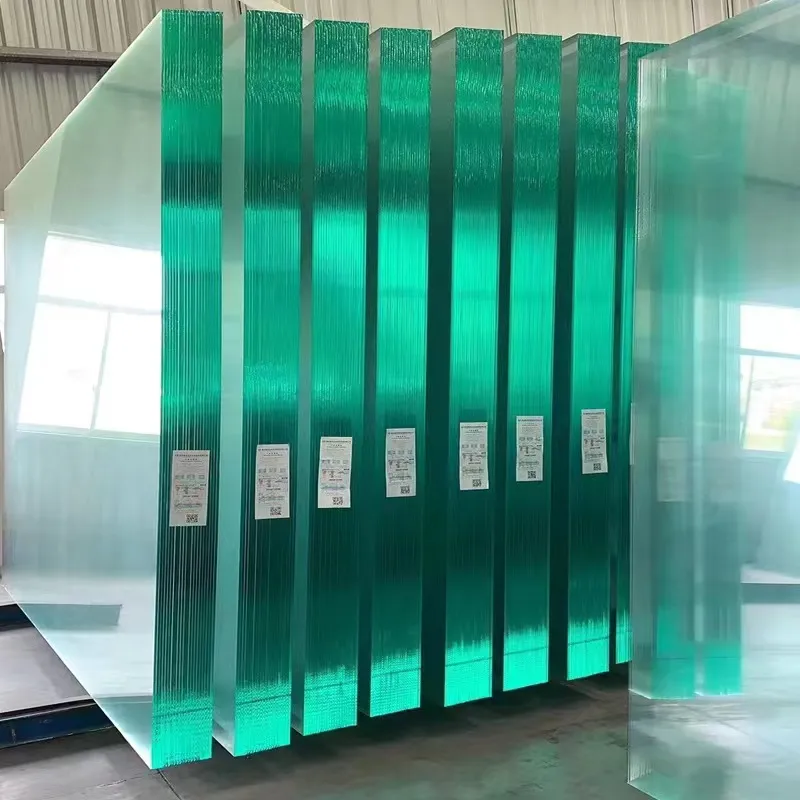

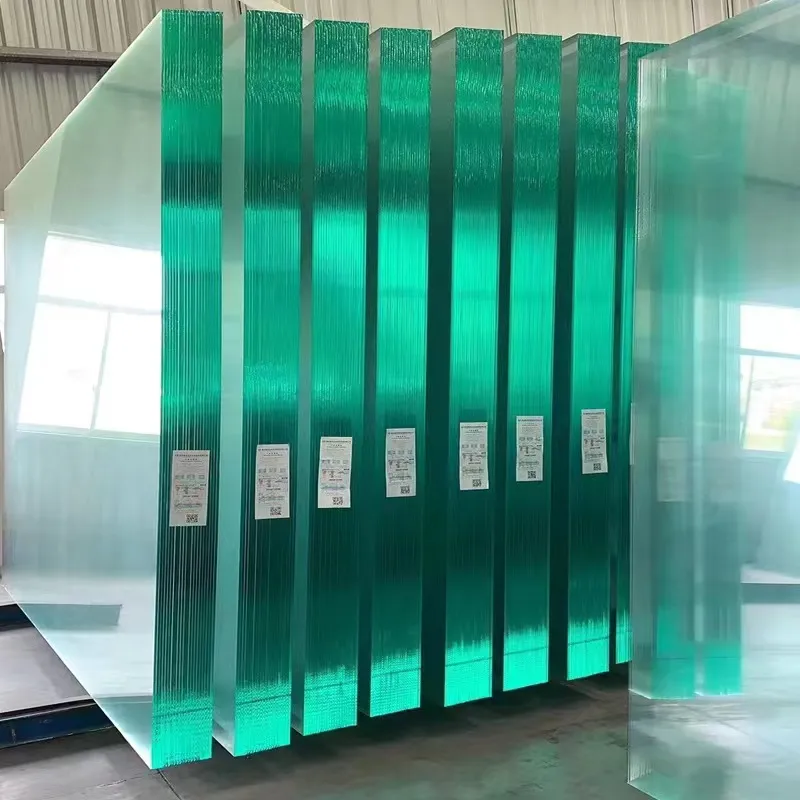

The precision involved in the float glass process is what sets it apart. It begins with melting raw materials at extreme temperatures, forming a perfect, molten glass ribbon. This ribbon is then floated over a bath of molten tin, allowing gravity and surface tension to create a perfectly flat surface. The glass gradually cools, solidifying into a continuous sheet with uniform thickness and a smooth, mirror-like finish. There are no rollers or air necessary during floating, which prevents the introduction of imperfections.

Not only does this method produce glass of exceptional quality, but it also significantly enhances production efficiency. Traditional methods often could not maintain consistent thickness, leading to material waste and higher costs. Float glass lines, in contrast, run continuously, minimizing interruptions and maintaining steady yield rates. This consistency in production translates to cost-effectiveness, which is passed down the supply chain, benefiting manufacturers and consumers alike.

Safety and environmental considerations are deeply embedded within the float glass process. The modern demands on sustainability are rigorous, and this method does not fall short. Recycling the raw materials and managing emissions are part of the operational protocol, illustrating the industry's commitment to sustainable practices. The energy use in float glass plants has decreased with innovations in technology, making it a frontrunner in eco-friendly manufacturing processes.

float glass process

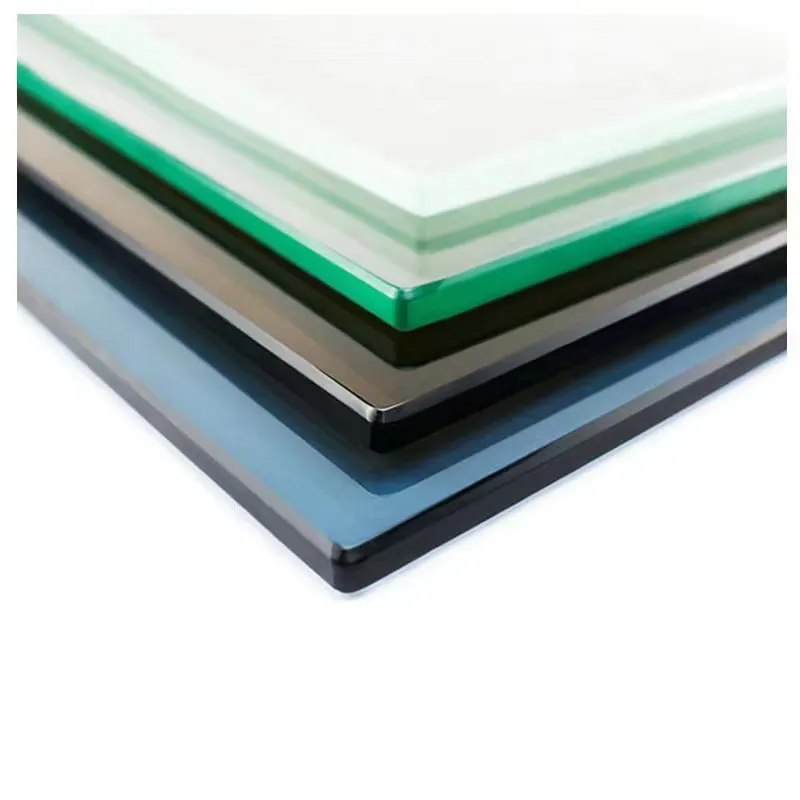

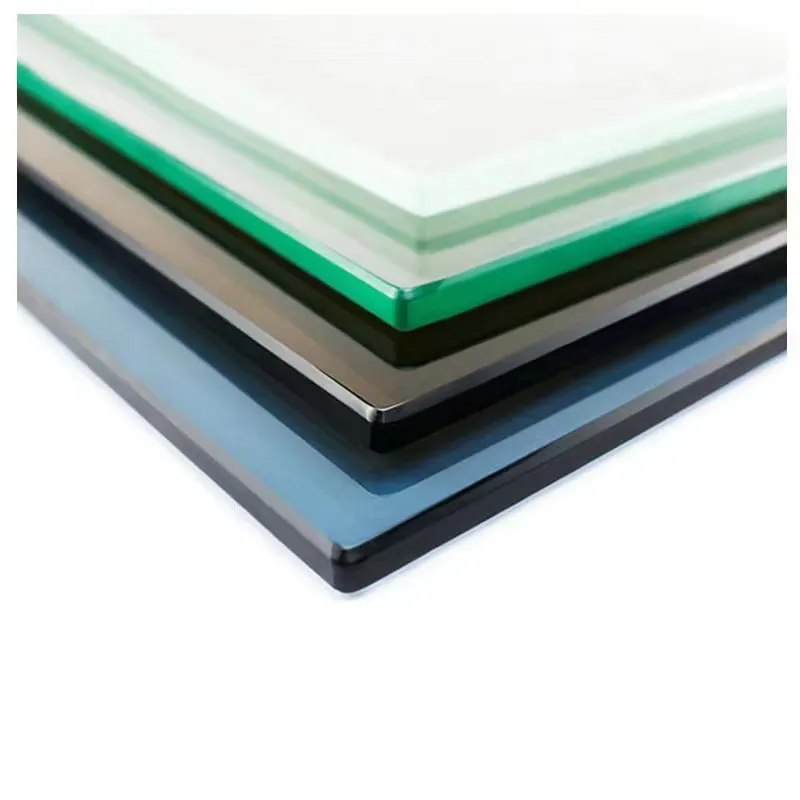

Technical progression in float glass production has also led to achievements in product diversity. Today, float glass can be coated for added functionalities like solar control, thermal insulation, and self-cleaning properties, opening up new possibilities for architects and designers. The seamless integration of high-precision manufacturing processes with customizable end products ensures that float glass remains at the forefront of material innovation.

In terms of expertise, float glass process engineers are specialized professionals trained extensively in the nuances of glass chemistry, thermal dynamics, and precision equipment handling. This not only ensures that each pane of glass adheres to strict quality standards but also underpins the trust consumers place in float glass products for their structural integrity and reliability.

The authority of the float glass process in the glass manufacturing industry is evident, having established itself as a cornerstone of modern building and automotive industries. Its transformative approach underscores the blend of tradition and innovation, reinforcing its trusted status worldwide.

Maintaining intrinsic trustworthiness, the float glass process stands as a testament to human ingenuity. With each pane produced, it reaffirms its role in shaping environments that are both beautiful and functional. The harmonious synergy of experience, expertise, and meticulous craftsmanship makes the float glass process an exemplary model in the realm of material production.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu