The float glass process, a sophisticated and innovative method, revolutionized the glass manufacturing industry. This technique, developed in the mid-20th century, stands as a testament to the power of engineering and ingenuity, creating a ripple effect that continues to influence today’s production techniques. Delving into its intricacies reveals why its mastery is not just beneficial but essential for modern glass production.

Central to the float glass process is the careful manipulation of raw materials—primarily silica sand, soda ash, and limestone. These elements are heated to their melting point in a furnace, creating a molten glass mixture. The furnace's design is crucial, maintaining temperatures around 1700 degrees Celsius and sustaining a uniform heat distribution to prevent imperfections within the glass.

Expertise in managing this molten state is vital. Once the desired melt is achieved, it is transferred onto a bath of molten tin within a controlled atmosphere. Herein lies the genius of the float glass method the liquid glass spreads onto the tin, forming a perfect sheet due to the latter’s smooth surface and lack of reactivity with glass. It is critical to maintain an incredibly precise control of the environment; the absence of oxygen mitigates oxidation of the tin, ensuring the glass remains pristine.

The production line features meticulous attention to detail, overseen by skilled engineers who monitor each stage. The glass's thickness is governed by adjusting the speed at which it moves over the tin. Adjustments, although seemingly minor, require profound technical proficiency and experience, as variations impact both the glass's physical characteristics and its refractive properties, tailoring it for specific applications.

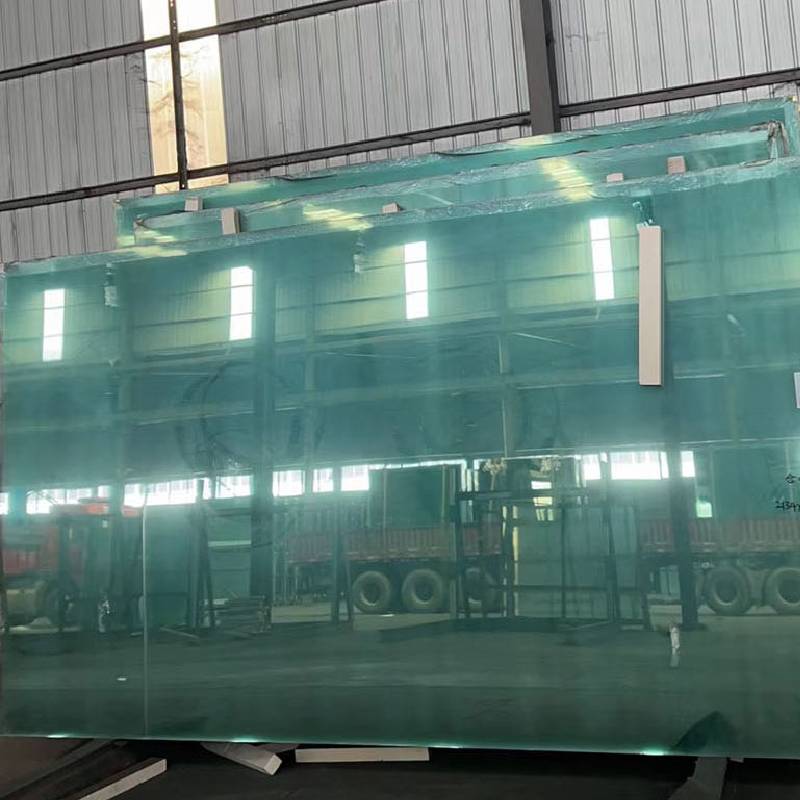

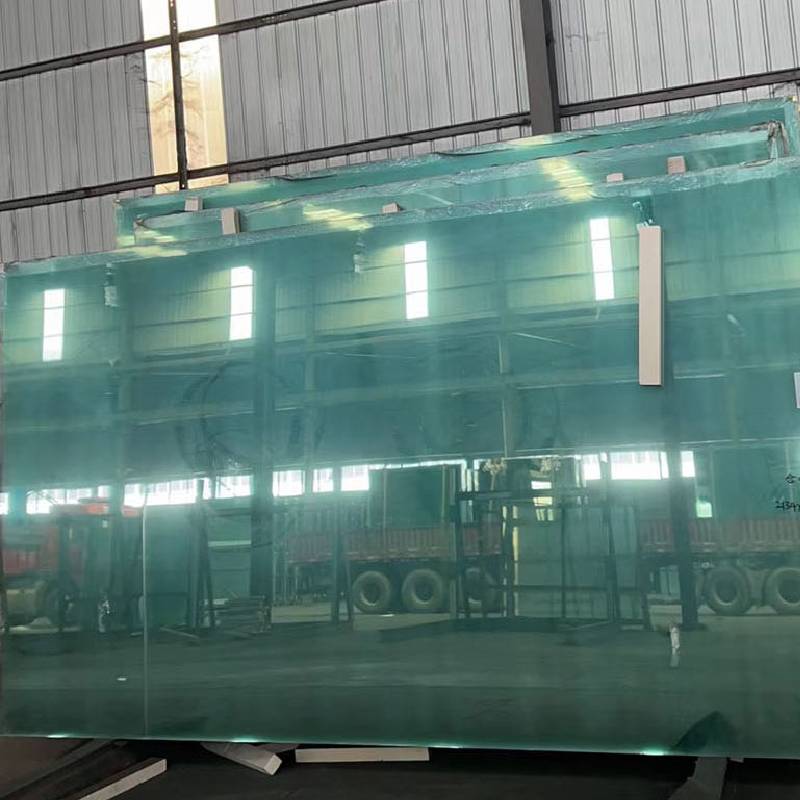

float glass process

As the glass cools, it gradually transitions from its liquid form into a solid state, a process that demands precision. The gradual cooling, or annealing, occurs within a lehr—a specialized kiln that alleviates internal stresses. This culminates in a product that exhibits superior structural integrity and optical clarity, characteristics that are non-negotiable in applications ranging from architectural installations to automotive windows.

The authority held by manufacturers in this domain is leveraged through continuous innovation and adherence to stringent quality control measures. From laboratory analysis to real-time monitoring with advanced sensor technologies, every step is documented and optimized. These efforts ensure the float glass meets and often exceeds international standards, such as ISO and ASTM, bolstering consumer confidence and reinforcing the trustworthiness of the product.

The sustainability of the float glass process adds another dimension to its allure. Modern adaptations have incorporated energy-efficient technologies, minimizing the environmental footprint. Utilizing recycled glass, or cullet, reduces the need for new raw materials, lowering energy consumption by 25% and demonstrating an industry-wide shift towards eco-conscious production practices.

In essence, mastering the float glass process encapsulates more than technical prowess; it involves an unwavering commitment to quality, innovation, and sustainability. This method remains unrivaled in producing glass that meets the ever-evolving demands of global markets—a testament to its enduring relevance and the continued need for expertise in its application. The companies that have honed and embraced these skills not only lead the market but also dictate the future of glass manufacturing.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu