The float glass process stands as a remarkable transformation in the manufacturing domain, seamlessly blending art and science to produce high-quality glass. This innovative technique has profoundly influenced multiple industries, highlighting its indispensable role across various applications, and ensuring it remains a cornerstone in contemporary glass production.

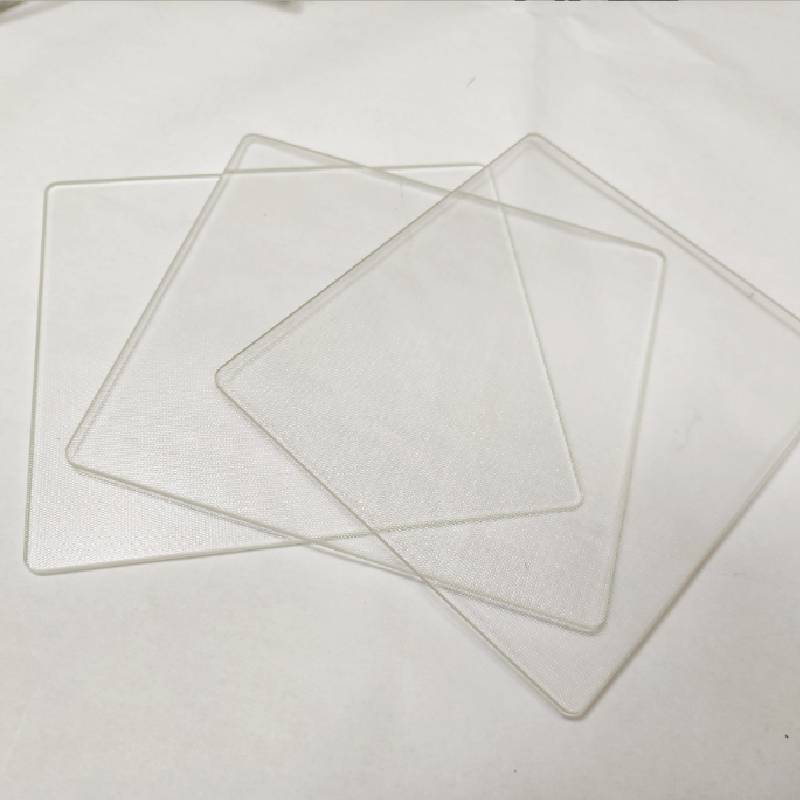

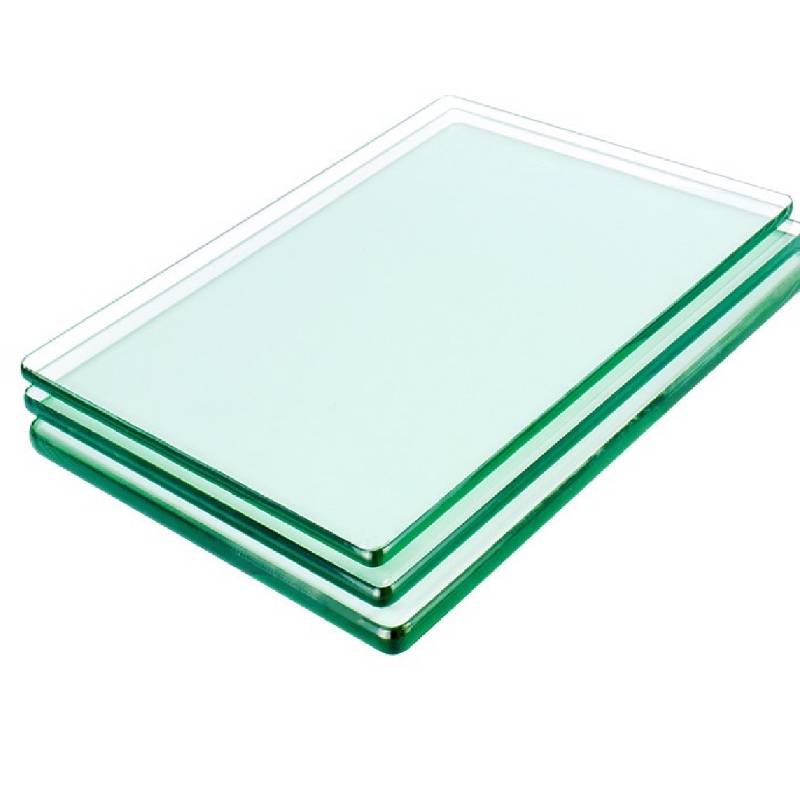

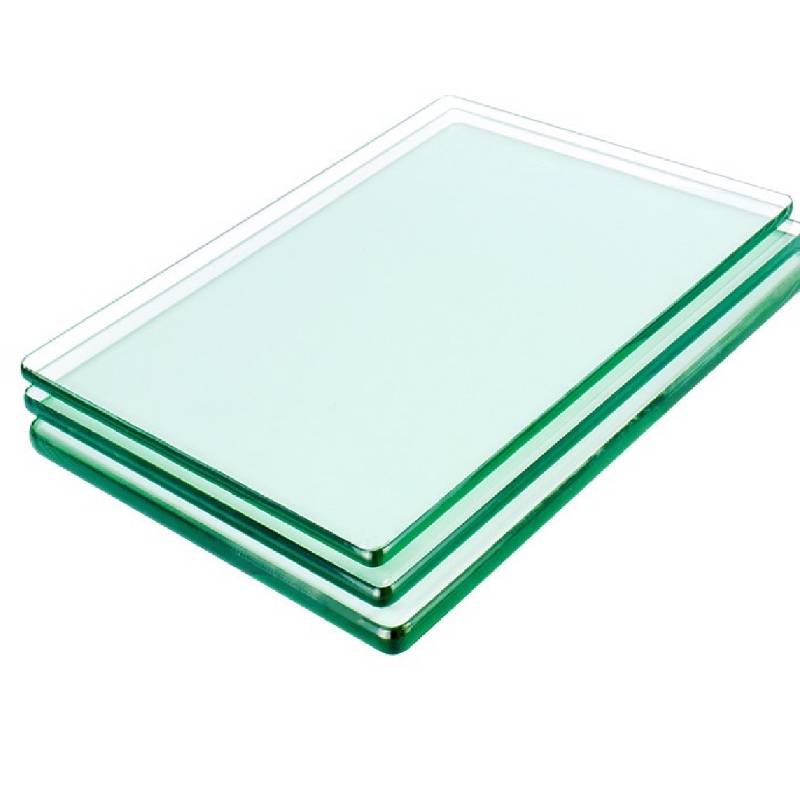

Originating in the mid-20th century, the float glass process was developed to revolutionize the glass industry by enabling the mass production of uniform, high-quality sheets of glass. The process involves floating molten glass on a bed of molten tin, allowing gravity and surface tension to work together to create a perfectly flat, smooth sheet. The method is economically advantageous, as it minimizes wastage and labor intensity compared to previous techniques, while maximizing the optical clarity and quality of the glass produced.

This technique's ascendancy is largely attributed to its ability to cater to the burgeoning demand for energy-efficient, aesthetically pleasing, and versatile glass products in both architectural and automotive sectors. The resultant glass is not just transparent; it can be further processed, tempered, and coated to enhance functionalities such as insulation, UV protection, and even self-cleaning capabilities. In commercial and residential buildings, float glass is pivotal in constructing windows, facades, and balustrades, where transparency meets strength and safety requirements. The automotive industry, too, relies heavily on float glass for windshields, side windows, and sunroofs, ensuring clarity and durability while adhering to stringent safety standards.

From an expertise standpoint, the float glass process exemplifies advanced thermal and mechanical engineering. Precision control is imperative in maintaining temperatures and environmental conditions within the float bath, demanding a symbiotic relationship between cutting-edge technology and skilled craftsmanship. Continuous innovations are found in refining the compositional elements of the glass, or improving the float bath’s infrastructure to withstand higher production speeds and capacities.

float glass process

The authority and trust in the float glass methodology are grounded in its consistent track record of delivering product excellence. By contributing to significant reductions in greenhouse gas emissions through the development of energy-efficient glass products, the float glass process showcases its alignment with global sustainability goals. Furthermore, renowned float glass manufacturers continuously set benchmarks within the industry, emphasizing not only the quality but also the ecological impact of glass production.

Real-world experiences corroborate the superior functional performance of float glass products. Architects and designers consistently laud the process for providing a competitive edge in aesthetics and performance. Retrospective data reveal that structures utilizing float glass inherently enjoy prolonged life spans and reduced maintenance costs, reinforcing its reputation as a resilient and cost-effective material choice.

As digitalization and automation continue to interlace with traditional manufacturing practices, the float glass process displays remarkable adaptability, integrating state-of-the-art controls and monitoring systems. This evolution ensures not only the enhancement of the glass's physical properties but also increased efficiency and scalability of production lines.

In conclusion, the float glass process is a testament to industrial progress, intertwining meticulous engineering with scalable production to cater to diverse market needs. Its role is not constrained to merely producing functional glass; it continues to pave the way for advancements in smart glass technologies and sustainable architecture. The ongoing enhancement in process technology and material science affirms the float glass process's position as an indispensable pillar in modern manufacturing and a keystone in the quest for sustainable development.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu