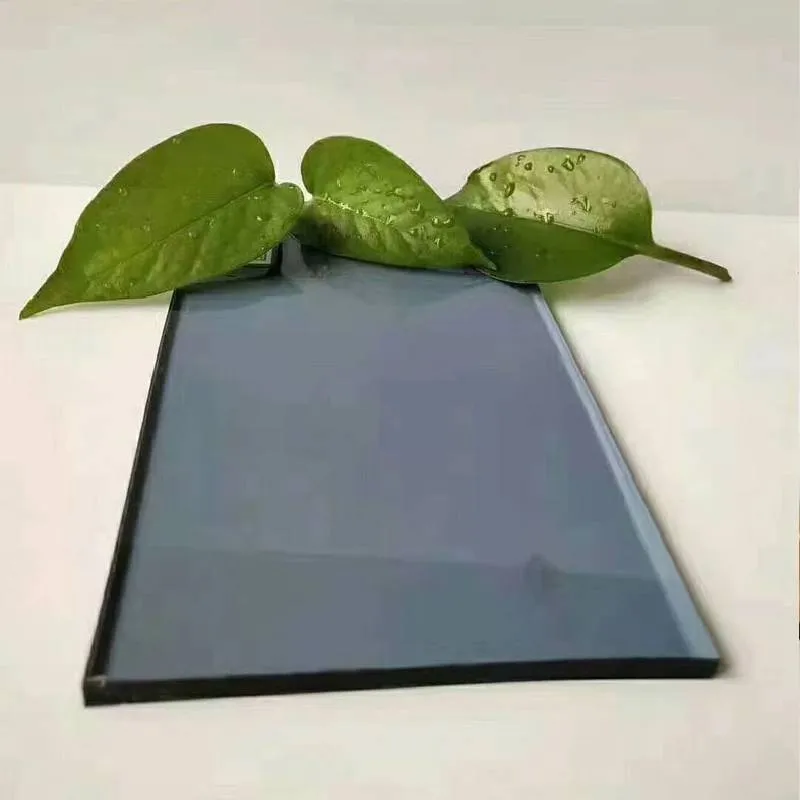

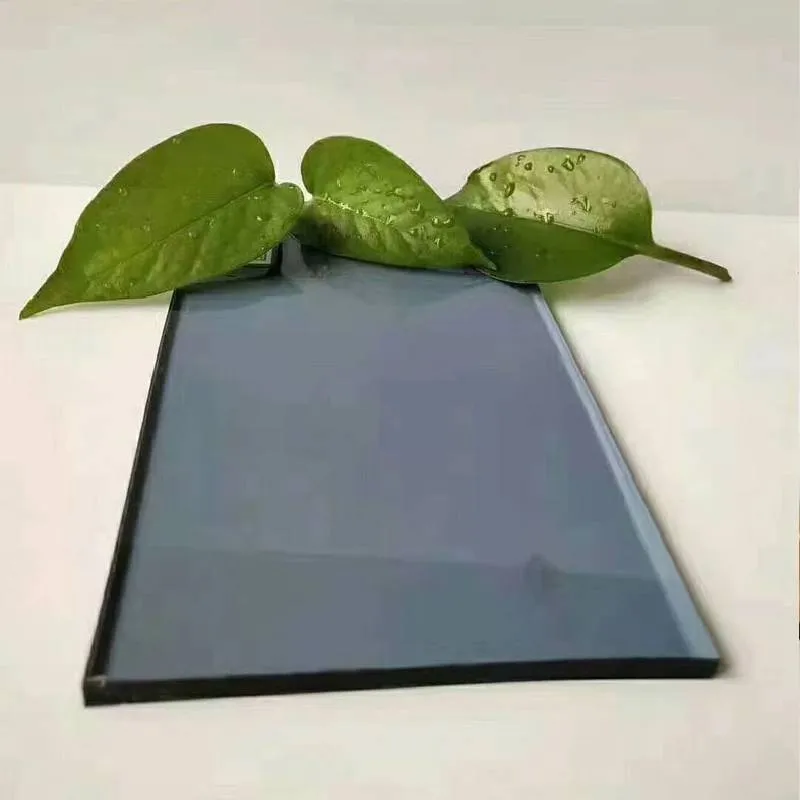

The float glass process, often unseen but profoundly influential, has revolutionized the production of flat glass. This method guarantees uniformly flat, high-quality glass suitable for a myriad of applications, from architectural projects to key components in solar panels and electronics. Rooted deeply in technical expertise and driven by constant innovation, the float glass process stands as a remarkable evolution in industrial manufacturing.

The inception of the float glass process in the 1950s marked a significant turning point. Developed by Sir Alastair Pilkington, this method addressed previous challenges in producing smooth, distortion-free glass sheets. It involves floating molten glass atop molten tin, utilizing the tin's higher density to ensure a perfectly even surface. This process not only streamlined production but also enhanced the quality significantly, eliminating the need for extensive polishing and grinding.

Deeply intertwined with the spheres of engineering and material science, the float glass process is a robust testament to human ingenuity. Experts note that maintaining the appropriate temperature throughout the process is crucial. The molten glass must be kept at approximately 1000 degrees Celsius initially, gradually decreasing to about 600 degrees as it solidifies. Achieving the ideal conditions demands a sophisticated understanding of thermal dynamics and materials engineering, underscoring the expertise required to optimize this process.

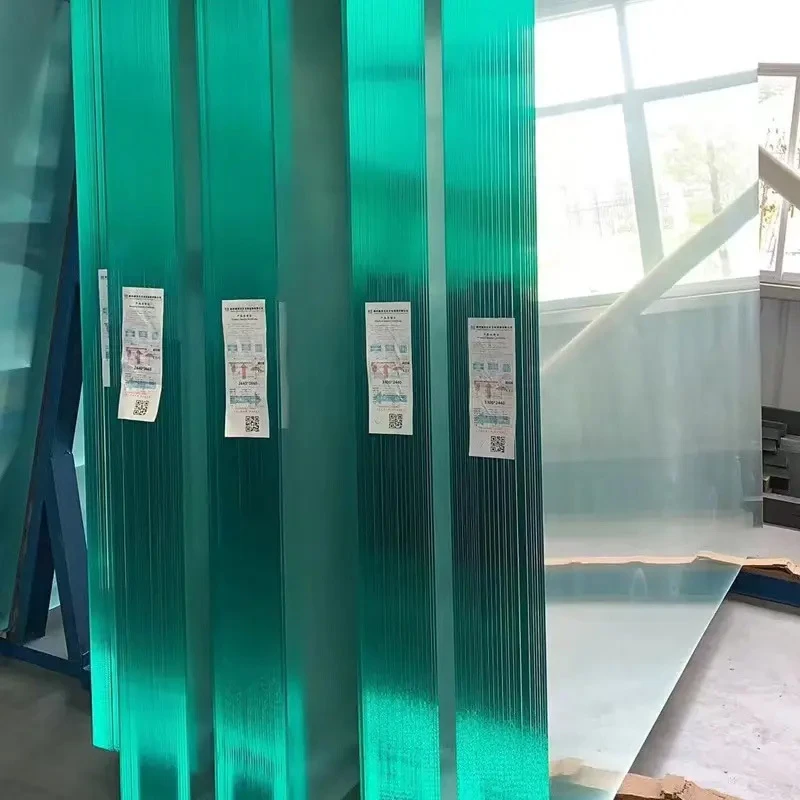

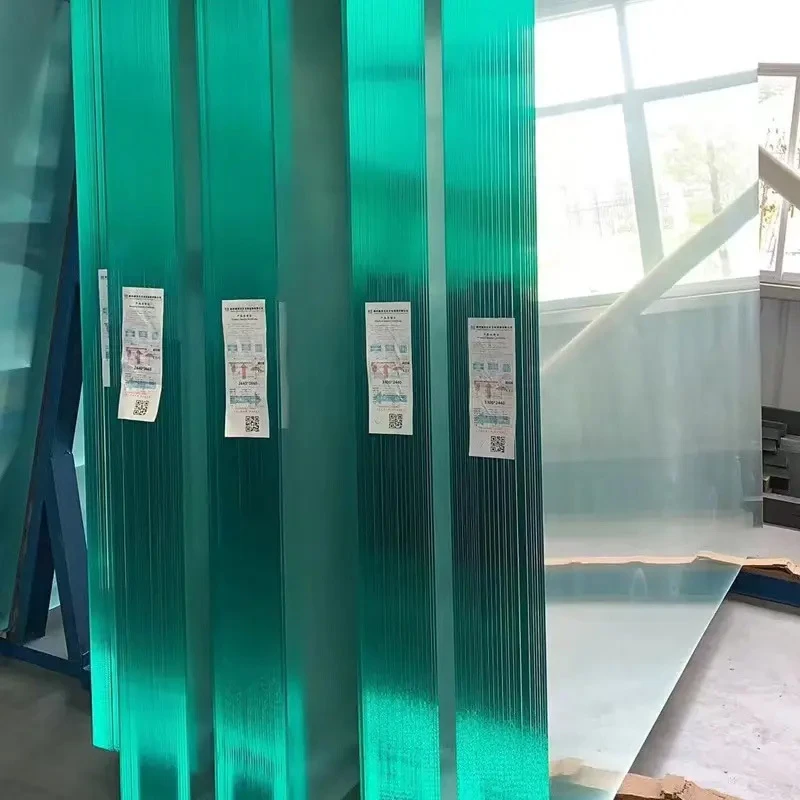

The technological advancements enveloping the float glass production are noteworthy for their precision and efficiency. State-of-the-art control systems monitor myriad variables such as temperature, glass thickness, and speed, ensuring products meet stringent quality standards. These advancements have cemented the process's authority in manufacturing circles, earning the trust of industries dependent on high-quality glass outputs.

float glass process

Authorities in the realm of glass production vouch for the float glass process as the predominant method due to its sustainability and efficiency. Tin, the core component in this process, is noted for its recyclability, and the method itself minimizes energy consumption when compared to older manufacturing technologies. The reduced need for post-production treatments lessens the overall environmental impact, aligning well with modern eco-conscious manufacturing standards.

Emphasizing trustworthiness, product consistency achieved through the float glass process has become foundational. Renowned construction companies and vehicle manufacturers rely on this process for glass that guarantees clarity and structural integrity. The dependability of float glass products strengthens trust across sectors, driving down operational risks and bolstering end-user satisfaction in various applications.

As float glass continues to touch everyday life—whether through the windows of skyscrapers or the intricate screens of personal devices—understanding its manufacturing foundation enriches the appreciation of its ubiquitous role. The journey of glass from a raw material to a refined product via the float glass process depicts a seamless blend of experience, expertise, and reliability. It sets a standard that influences future innovations in the manufacturing domain, standing as a pillar of quality and environmental consciousness in the modern era.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu