When selecting materials for construction and renovation, laminated glass and tempered glass stand out as two pivotal choices. Understanding their respective strengths and applications is essential for making an informed decision.

Laminated glass, often hailed for its safety and sound insulation properties, consists of two or more layers of glass bonded together with one or more layers of polyvinyl butyral (PVB) interlayer. This composition provides an extraordinary advantage when broken, laminated glass tends to hold together, minimizing injury risks. This key feature makes it an ideal choice for windows, skylights, and curtain walls in architecture, particularly in regions prone to natural disasters such as hurricanes or earthquakes. Its ability to block up to 99% of ultraviolet rays also helps in protecting interiors from fading and damage, enhancing the longevity of furniture and other fittings.

On the other hand, tempered glass is known for its exceptional strength and thermal resistance. During its manufacturing process, tempered glass is heated to over 600 degrees Celsius and then rapidly cooled. This process results in a product that is up to five times stronger than standard glass. One of the most significant advantages of tempered glass is its behavior upon breaking it shatters into small, granular chunks instead of jagged shards, reducing the risk of serious injury. This makes it a popular choice for applications where human safety is a concern, such as in shower doors, glass doors, and office partitions. Its resistance to thermal stress makes it suitable for environments with significant temperature variations.

Both laminated and tempered glass exhibit expertise and authoritativeness in their respective domains. For instance, automotive manufacturers commonly opt for laminated glass for windshields due to its sound-dampening properties and ability to remain intact, providing a safety barrier for passengers. Conversely, tempered glass is widely used in the side and rear windows of vehicles owing to its strength and safe fragmentation pattern upon impact.

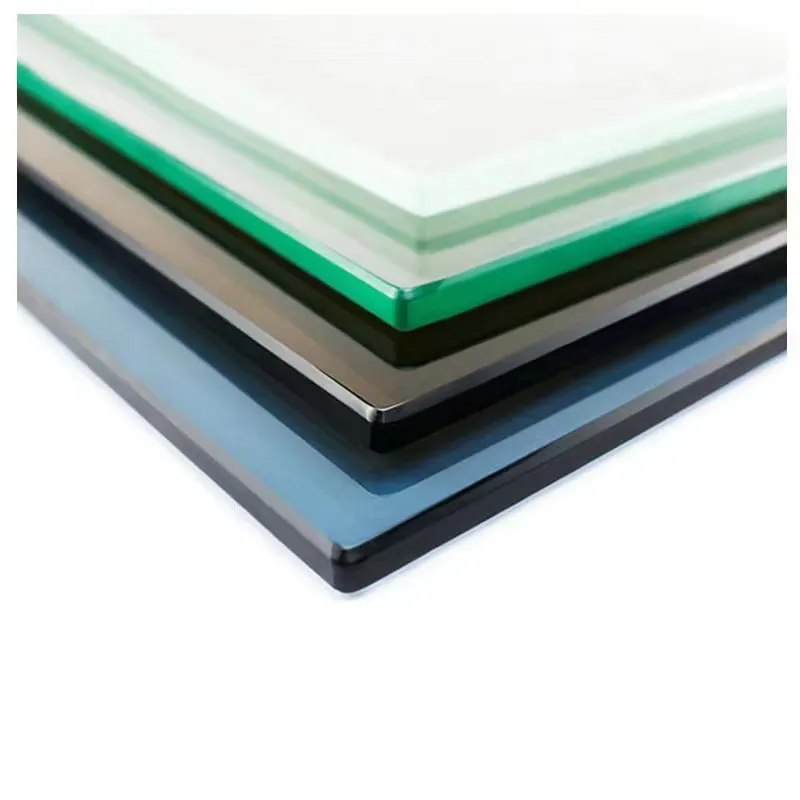

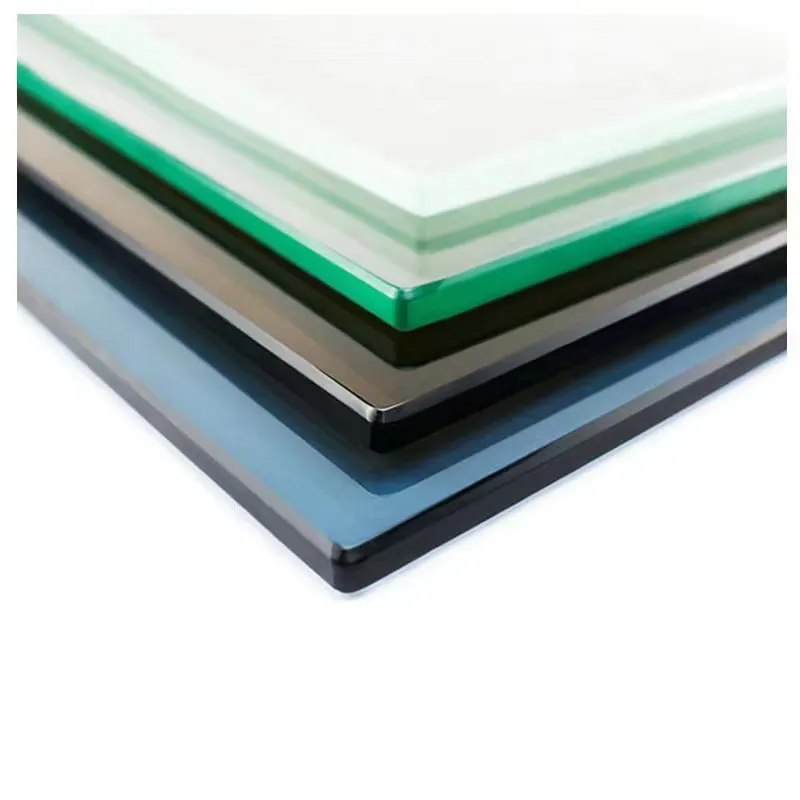

laminated glass tempered glass

From an expert perspective, the selection between laminated and tempered glass hinges on the intended application and specific requirements of a project. While laminated glass is preferable for applications necessitating sound insulation, UV protection, and impact resistance, tempered glass is more suited to areas demanding high strength and thermal shock resistance.

Authoritative research and experience indicate that, while both types of glass meet fundamental safety and durability needs, their unique features cater to different preferences and functional purposes. Therefore, the architectural and design industries prioritize understanding the nuances of these materials to ensure the highest standards of building safety and comfort.

In the realm of trustworthiness, both laminated and tempered glass have undergone rigorous testing to meet international safety and quality standards. Their widespread use and endorsement by industry professionals testify to their credibility and reliability. By selecting the appropriate type of glass, consumers can enhance the structural integrity and aesthetic appeal of their projects while ensuring the safety and well-being of occupants.

Ultimately, choosing between laminated glass and tempered glass involves a balance of safety considerations, structural requirements, and aesthetic preferences. With both options offering distinct advantages, the decision should be based on specific project needs, ensuring optimal performance and satisfaction. The expertise embedded in these materials promises not only enhanced safety but also a superior quality of life within the constructed environment.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu