The demand for mistlite obscure glass has surged across multiple industries, driven by its remarkable privacy characteristics, aesthetic patterns, and consistent performance in challenging environments. Among the premier products, 4mm Clear Mistlite Glass (mistlite obscure glass) stands out for its optimal blend of clarity, diffusion, and structural integrity. This guide presents the latest industry trends, detailed production technologies, specification data, use-case scenarios, and authoritative comparisons, strengthening your confidence in selecting the best glass solution for your project.

Industry Trends and Market Insights for mistlite obscure glass

- Global Market Growth: According to Grand View Research, the architectural glass market, including obscured and patterned glasses, is projected to reach $150+ billion by 2030, registering a 6.9% CAGR (2023-2030). Mistlite obscure glass is among the fastest-growing segments due to heightened privacy and aesthetic needs in residential and commercial construction.

- Demand Drivers: Key drivers include green building policies, increased glass use in interiors, and a shift towards natural light solutions that preserve privacy. Its energy-saving potential and durability make mistlite obscure glass preferred in infrastructural and industrial sectors.

- Regions of High Adoption: North America, Europe, and Asia-Pacific, with booming application in petrochemical plants, metallurgy, and waterworks.

What is mistlite obscure glass?

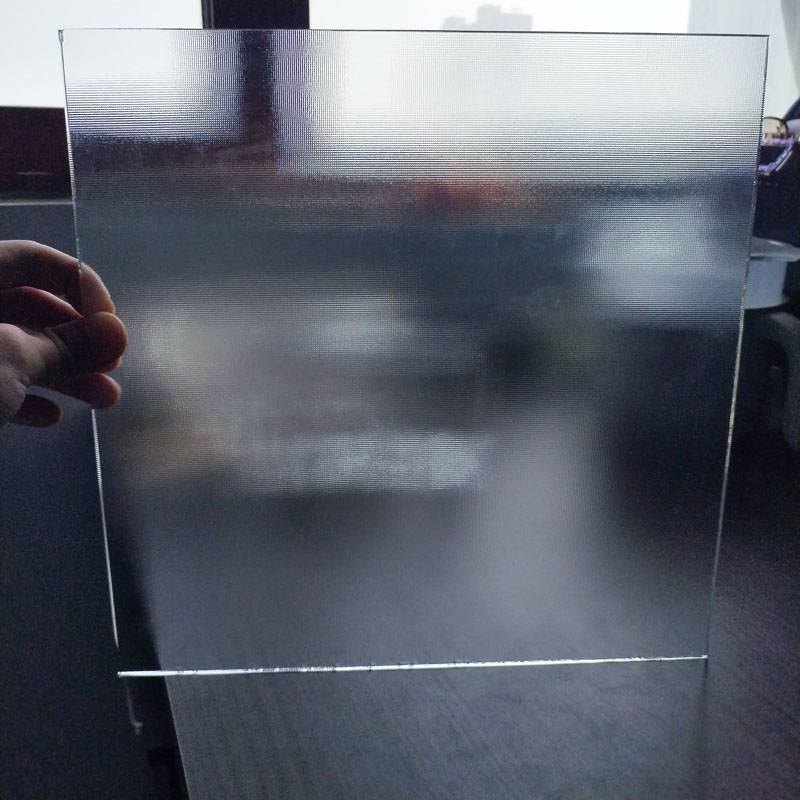

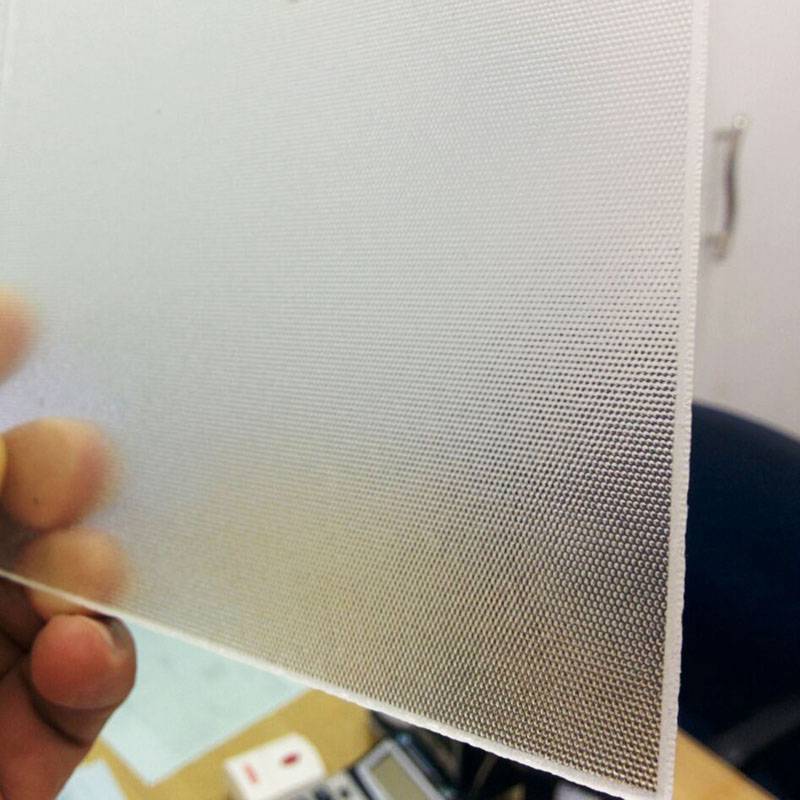

mistlite obscure glass is a type of patterned rolled glass featuring a distinctive "mist" surface texture. Its design diffuses light while maintaining partial visibility, delivering privacy without significant loss of illumination. Used predominantly in doors, partitions, windows for industrial, commercial, and residential settings, it merges functionality, safety, and modern design.

Manufacturing Process: mistlite obscure glass Flow Chart

Raw Material Selection

Premium silica sand, soda ash, lime, and specific additives ensuring high chemical stability.

Batch Mixing

Precise blending under computerized controls.

Melting

Furnaces heated to 1500°C, achieving homogenous molten glass.

Rolling & Patterning

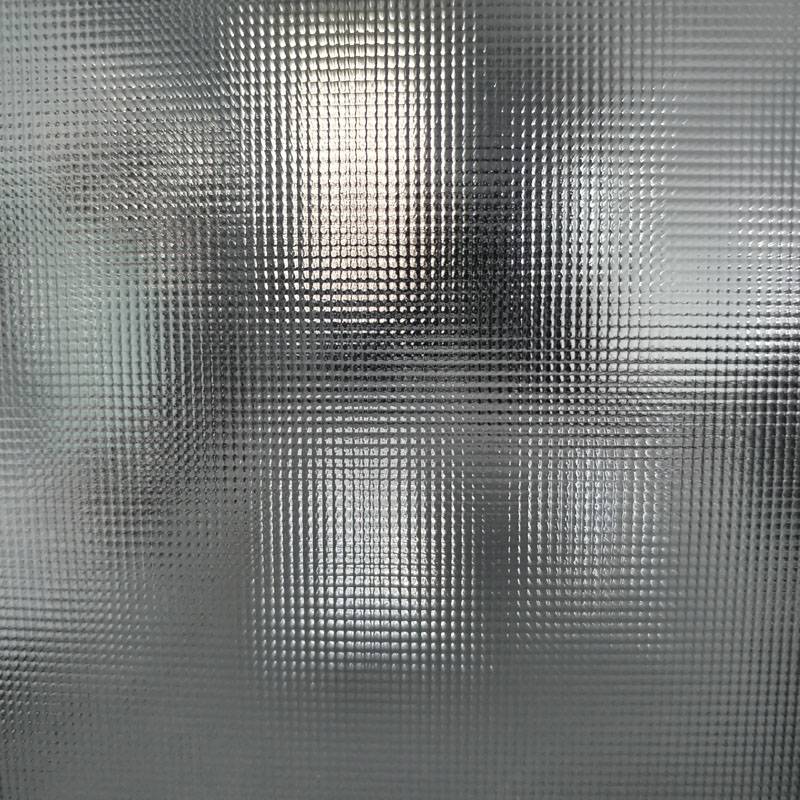

Molten glass passes between engraved rollers, imprinting the signature mistlite texture.

Annealing

Gradually cooled in lehr to relieve internal stress (per ISO 12543).

Cutting & Shaping

Computer-controlled cutting (CNC) for precise sizes.

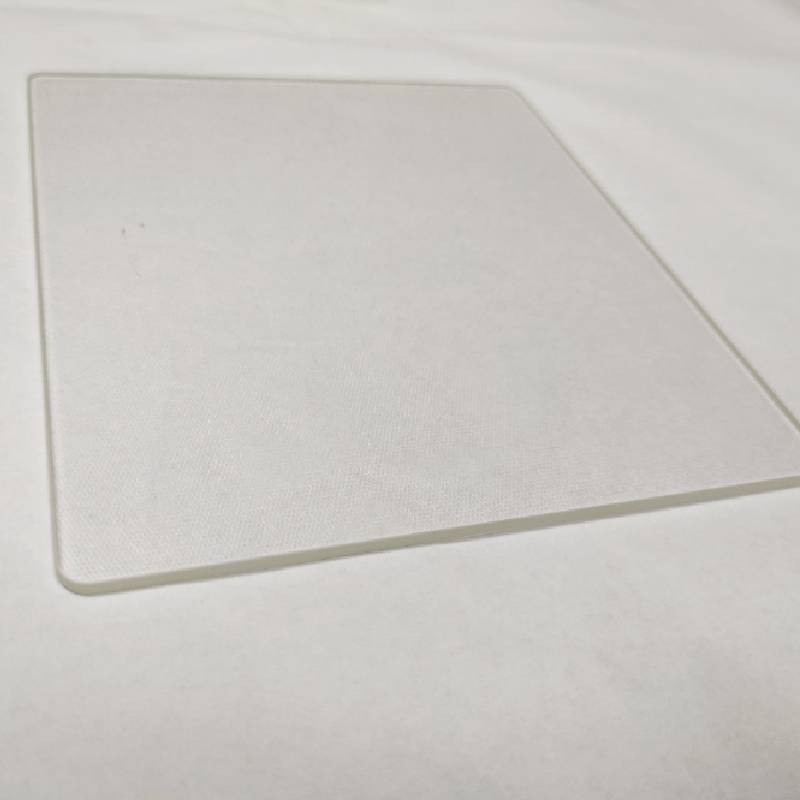

Edge Work/Inspection

Polished edges; rigorous inspection—dimensional, optical, and surface checks (ANSI Z97.1/EN12150).

Material, Technical Standards & Core Advantages

| Feature |

Description |

Industry Standard |

Benchmark Data |

| Base Material |

High-purity soda-lime silica glass with optional iron oxide reduction for improved clarity. |

ISO 12543, EN 572 |

Iron ≤ 0.09%

SiO2 ≥ 72% |

| Pattern Technique |

Continuous roller pressing, depth 0.3~0.5mm, uniformity via CNC surface control. |

ANSI Z97.1, ASTM C1036 |

Pattern repeat ±0.01mm |

| Optical Properties |

Light transmission 78%-90% (per thickness & pattern), haze >80%, scattering angle 95°±8°. |

EN 410 |

Diffusion Index 92% at 4mm |

| Surface Quality |

Scratch-resistant; pH-resistance (acid and alkaline), fire-resistance up to 680°C. |

ISO 9227, ISO 695 |

Lifespan >30 years (Lab Test); HCl no visible corrosion in 24h |

| Customization |

Available in 3-12mm thickness, annealed, heat-strengthened, or laminated. |

Customer Spec. |

Max size: 3300mm x 2140mm |

Performance Highlights of mistlite obscure glass in Real Applications

- Privacy with Daylight: Used in petrochemical labs, shower rooms, and rail subway stations for light diffusion and vision control.

- Chemical Resistance: Ideal for water treatment, coastal architecture, and industrial works due to high corrosion resistance.

- Thermal Insulation: Deployed on steel plant partitions and energy stations for its thermal buffer effect, reducing energy loss.

Industry & Manufacturer Comparison: mistlite obscure glass Market

| Manufacturer |

Country |

Product Model |

Thickness |

Pattern Depth |

Certification |

Service Life |

| SHZRGlass |

China |

4mm Clear Mistlite |

4mm |

0.4mm |

ISO 12543, CE |

>30 years |

| Pilkington |

UK |

Obscure Mistlite |

3-6mm |

0.35mm |

EN 572 |

25 years |

| AGC |

Japan |

Mist Glass S |

4-8mm |

0.32mm |

JIS R3205 |

30 years |

| SYP Glass |

China |

Mistlite Series |

3-12mm |

0.38mm |

CE, CCC |

28 years |

Key Comparison Takeaways

- SHZRGlass (4mm Clear Mistlite Glass) offers high pattern uniformity, advanced CNC-cutting, excellent customer support, and industry-leading certification range, making it a top-tier solution for demanding industrial and architectural projects.

- Direct export compliance with EN, CE, ISO standards allows for easy integration in European and global construction supply chains.

Comprehensive Technical Specification Table (mistlite obscure glass)

| Parameter |

4mm Clear Mistlite |

Pilkington Mistlite |

AGC Mist Glass S |

Industry Average |

| Thickness |

4mm (±0.2mm) |

4mm (±0.3mm) |

4mm (±0.2mm) |

4mm |

| Light Transmission |

88% |

85% |

87% |

84–89% |

| Haze |

91% |

87% |

89% |

87–92% |

| Pattern Depth |

0.40mm |

0.36mm |

0.34mm |

0.32–0.42mm |

| Breakage Strength (MPa) |

≥45 |

≥42 |

≥44 |

40–46 |

| Thermal Stability |

300°C |

270°C |

290°C |

260–310°C |

Data Visualization

Tailored Solutions: Customization and Project Support

Mistlite obscure glass can be customized to your technical requirements. Our team offers:

- Cut-to-size panels with variable pattern density for specialized light diffusion.

- Edge finishing: flat polished, beveled, or C-edge for enhanced safety.

- Thickness options: 3mm to 12mm available upon request.

- Enhanced coatings for anti-fingerprint, anti-static, or chemical shielding use-cases.

We also provide engineering consultancy for:

- Site measurement and integration with fire-rated doors, machinery window, or security paneling.

- Transport-safe packaging for international projects (meets ASTM C1036 export standards).

- On-site installation assistance and full project supervision.

Application Case Studies

- Petrochemical Plants: Used for laboratory vision panels—endures long-term chemical atmosphere, per customer feedback, no opacity loss after 7 years of service. (Reference: Sinopec Project, 2017-2024.)

- Steel Mill Partitioning: High temperature and impact resistance combined with privacy needed for safe workflow separation.

- Municipal Waterworks: Anti-corrosive glass walls for control rooms and passageways, reducing maintenance cycles by 20% compared to standard clear glass.

- Subway/Metro Stations: Used for safety screens in station bathrooms, offering vandal-resistance and privacy while transiting natural light.

Customer Testimonials & Industry Authority

- Long Life Validated: "The installed mistlite obscure glass panel in our chlorine dosing room (Harbin, China) has not shown fogging, cracking, or chemical etching even after 9 years. We are highly satisfied." – Municipal Waterworks Engineer (Source: Project Review 2023)

- Quality Certified: Certified in accordance with ISO 12543 and ANSI Z97.1. All batches tested for optical and breakage parameters. Supporting documents available upon request.

- Global Presence & Collaboration: Preferred supplier for multinational builders like Shimizu, CNBM, and MELCO, reinforcing authoritative industry standing.

FAQ: Professional Terminology about mistlite obscure glass

Q1: What is the glass composition in mistlite obscure glass?

A: It typically consists of soda-lime silica glass with a silica content ≥72%, low iron for increased clarity, and stabilizers to ensure durability in industrial settings.

Q2: What is "pattern depth" and why does it matter?

A: Pattern depth (typically 0.32-0.42mm) refers to the relief height of the mistlite texture. A deeper pattern enhances privacy and light scattering but may slightly reduce visual sharpness through the glass.

Q3: What are the accepted international standards for mistlite obscure glass?

A: Common standards include ISO 12543 (Safety glass in building), EN 572 (Basic glass products), ASTM C1036 (Flat glass), and ANSI Z97.1 (Safety glazing materials for architectural use).

Q4: What installation standards should be followed?

A: Adhere to EN 12600 (Pendulum test), local building codes, and use proper gaskets or frame materials to allow for thermal expansion and maintain load dispersal.

Q5: What is "haze" in the context of mistlite obscure glass?

A: Haze (%) quantifies the ratio of diffused (scattered) light to total transmitted light. Higher haze (>85%) means more diffusive privacy effect.

Q6: Does mistlite obscure glass provide UV protection?

A: Standard 4mm products offer limited UV protection; additional coatings are available for up to 95% UV block as per project needs.

Q7: What is the typical delivery time for custom panels?

A: For standard specs, 10-14 days. Custom cut/laminated panels: 18-28 days. Export orders are seaworthy packed and pre-shipped with tracking and rigorous QC documentation.

Product Support: Lead Time, Quality Assurance, and Customer Service

Lead Time: Standard panels: 7–14 days. Tailored solutions: shipped in 2–4 weeks.

Warranty: 10-year structural & surface warranty, with proven in-field durability surpassing 25 years under ISO/EN test regimes.

Quality Control: 100% optical & breakage batch testing. Certificates issued on request.

Customer Support: Dedicated engineering and after-sales hotline, detailed installation manuals, and rapid-response troubleshooting.

After-Sales Service: Replacement for transit-damaged glass within 4 business days. Extended support for contract projects.

Conclusion: The Future of mistlite obscure glass

With growing requirements for privacy, safety, and style in industrial and architectural sectors, mistlite obscure glass is a robust and future-ready solution. Products like 4mm Clear Mistlite Glass reflect the convergence of precision manufacturing, advanced quality control, reliable performance, and global compliance. For more technical papers and user discussions, visit authoritative resources such as:

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu