Introduction: Clear Float Glass

Clear float glass is the global standard in flat glass manufacturing, widely used in construction, automotive, furniture, and other industries. With technological advancements and architectural innovation, the demand for clear float glass continues to rise worldwide. This article covers industry trends, technical data, common applications, a detailed FAQ, and visualized analytics of key products such as 10 mm plain glass price, 10mm clear glass price, 12mm clear glass price, and 4mm clear float glass.

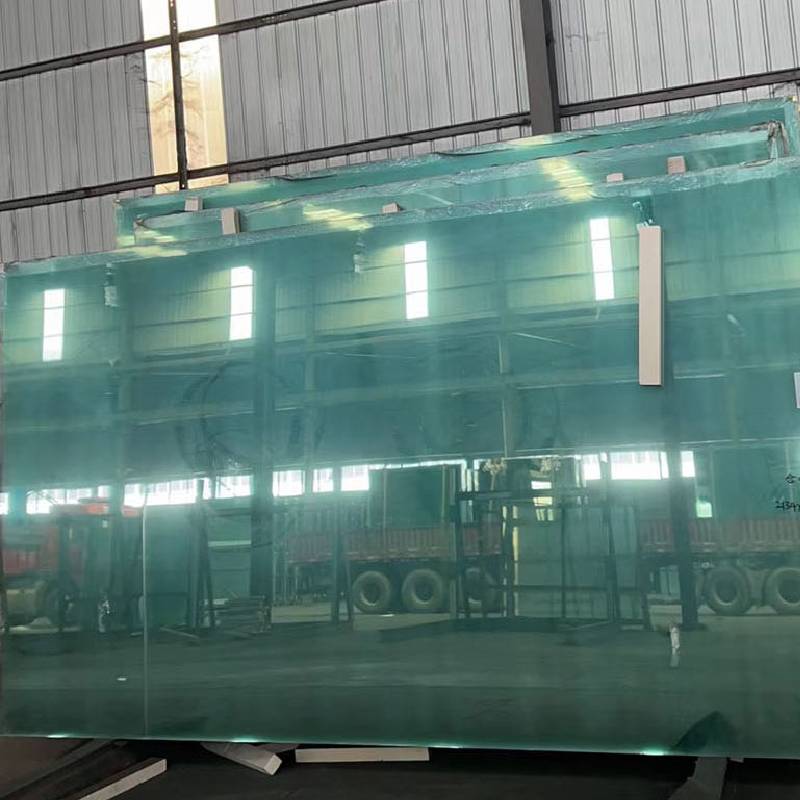

Product Overview: Clear Float Glass

Clear float glass is produced by combining high-quality sand, natural ores, and chemical materials, then melting them at elevated temperatures. The molten glass flows into a tin bath, where it is spread, polished, and formed into an even sheet. This process ensures a surface with minimal distortion, high optical clarity, chemical stability, and mechanical strength.

Key advantages include: acid, alkali, and corrosion resistance, excellent light transmittance, and suitability for further processing (tempering, laminating, coating, etc.). Explore the product in detail:

Clear Float Glass Product Page.

- Product: Clear float glass

- Thickness Range: 2mm - 22mm

- Common Sizes: 1830×2440mm, 2134×3300mm, Custom cut

- Applications: Curtain walls, doors & windows, partitions, furniture, automotive, etc.

Industry Trends & Market Landscape

The clear float glass industry remains robust, driven by the construction boom, green building mandates, and advancements in glazing technology. According to GlassOnWeb and the Glass Magazine, float glass accounts for over 80% of the world's flat glass market thanks to its quality, versatility, and economies of scale.

Over the last 5 years, the market has seen:

- Significant price fluctuations in raw materials (silica sand, soda ash, energy)

- Increased demand for 10 mm plain glass and specialty thicknesses (4mm, 10mm, 12mm) for safety, energy-efficiency and sound insulation

- Investment in low-iron and high-transparency variants

- Expansion of application in green buildings and smart facades

Technical Parameters of Clear Float Glass

In selecting clear float glass, several technical indicators should be considered, including thickness, visible light transmittance, mechanical strength, and chemical resistance. Below is an overview of industry-standard parameters for key product thicknesses (source: ScienceDirect).

| Specification |

Thickness (mm) |

Density

(g/cm³) |

Light Transmittance (%) |

Bending Strength (MPa) |

Price Range

(USD/㎡) |

| 4mm clear float glass |

4 |

2.5 |

89-90 |

65 |

4.2 ~ 6.5 |

| 10 mm plain glass |

10 |

2.5 |

84-86 |

75 |

10.5 ~ 13.8 |

| 10mm clear glass |

10 |

2.5 |

84-86 |

75 |

11.0 ~ 15.0 |

| 12mm clear glass |

12 |

2.5 |

82-85 |

82 |

16.0 ~ 20.0 |

Clear Float Glass Market Price Trend (2020–2024)

Technical Comparison: 4mm, 10mm, 12mm Clear Float Glass

Market Share by Thickness (Current Data)

Key Applications of Clear Float Glass

Clear float glass is widely applied due to its clarity, flatness, and high processability:

- Architecture: Curtain walls, windows, partitions, doors, skylights, canopies

- Interior: Railings, balustrades, mirrors, decorative glass panels, tables

- Automotive: Vehicle windows, sunroofs, windshields (after laminate/temper)

- Solar Energy: Solar panels, greenhouses (as cover glass)

- Appliance & Electronics: Displays, touch panels, refrigerator doors, lighting

Modern design increasingly demands

10 mm and

12mm clear glass for strength and aesthetics in premium buildings.

Advantages of Clear Float Glass in Modern Architecture:

- High light transmittance, enhancing natural illumination

- Excellent performance in sound proofing (with laminated/insulated units)

- Compatible with numerous glass processing techniques (tempering, coloring, coating)

- Cost-effective for large-area glazings compared to low-iron glass

Clear Float Glass Professional FAQ

Q1: What is the main material composition of clear float glass?

A: The primary ingredients are high-purity silica sand, soda ash (sodium carbonate), limestone (calcium carbonate), dolomite, and cullet (recycled glass). These materials undergo precision mixing to ensure consistency and clarity.

Q2: What are the standard thicknesses and edge finishes available?

A: Standard clear float glass thicknesses range from 2mm to 22mm. Edge treatments can include arrissed (seamed), polished, beveled, or cut to custom specifications.

Q3: What are the typical mechanical and chemical properties?

A: Typical mechanical strength (bending) is 65 - 85 MPa; compressive strength can be upwards of 700 MPa. Float glass is highly resistant to acidic/alkaline corrosion and shows minimal color shift in daylight conditions.

Q4: How is clear float glass priced (e.g., 10mm, 12mm)?

A: Price is mainly a function of thickness, size, quality, and order volume. 10 mm plain glass price is approximately $10.5–$15/㎡, while 12mm clear glass price ranges from $16–$20/㎡ (2024 data).

Q5: What standards and certifications apply?

A: Clear float glass is produced per EN 572 (Europe), ASTM C1036 (USA), and ISO 9050 guidelines, ensuring dimensional precision, optical quality, and performance compliance.

Q6: Can clear float glass be tempered or laminated?

A: Yes, it is the ideal base material for further processing such as toughening (tempering), lamination, mirroring, or coating for energy saving or privacy.

Q7: What are the primary installation and handling requirements?

A: Installation should follow appropriate standards (e.g., EN 1096 for facade glass), allow for thermal expansion, and support the glass perimeter on neoprene blocks. Edges must be protected to avoid chipping or spontaneous breakage.

EEAT Focus: Expertise, Authority, and Trustworthiness

Why Choose Zhuoruiglass for Your Clear Float Glass Needs?

- Over 20 years of manufacturing/supply chain expertise in float glass

- Custom sizing, fast delivery, full traceability, and responsive technical support

- Exported to 50+ countries, with projects featured in iconic architecture

Conclusion

As architectural and industrial applications expand, the strategic choice of high-quality clear float glass ensures safety, aesthetics, and performance for every project.

For the latest trends, specification guidance, or to source 10 mm plain glass, 10mm clear glass, 12mm clear glass at competitive prices, contact Zhuoruiglass via email or WhatsApp.

References:

- GlassOnWeb: Float Glass Industry & Future Trends

- Glass Magazine

- ScienceDirect: Float glass: Properties and Manufacturing

- Glass Performance Days Conference Proceedings

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu