Toughened glass, often referred to as tempered glass, stands as a cornerstone in the realm of advanced materials for a plethora of products in various industries. Known for its unmatched strength and safety features, toughened glass material offers a unique blend of durability and versatility that is critical in today's demanding environments.

The production of toughened glass involves a specialized heat-treatment process where standard glass is heated to over 600 degrees Celsius and then rapidly cooled. This tempering process alters the internal structure, attributes that provide the glass with its renowned durability, making it approximately four to five times stronger than untreated glass. This remarkable strength is not just theoretical; having been tested under rigorous conditions, toughened glass proves its mettle in real-world applications.

For instance, consider vehicular applications, particularly in automotive windshields. A minor accident could lead to catastrophic consequences with ordinary glass, but with toughened glass, the chance of critical injury reduces significantly. Unlike regular glass that breaks into sharp shards, toughened glass shatters into small granules that are far less likely to cause harm.

In the architectural space, skyscrapers extensively utilize toughened glass. Its capacity to withstand high winds and impacts from debris provides both an aesthetic and functional advantage. Large glass facades not only improve natural lighting and visual appeal but also contribute to energy efficiency. This material's strength is crucial in ensuring that buildings meet safety codes while maintaining an elegant design.

Consumers often encounter toughened glass in everyday products, such as smartphone screens and household appliances. The adoption of this material in smartphones ensures the screens are resistant to scratches and cracks, maintaining usability even after unexpected drops. Similarly, in kitchen environments, toughened glass on stoves and oven doors is essential to endure high temperatures and resist breakage, enhancing both safety and longevity.

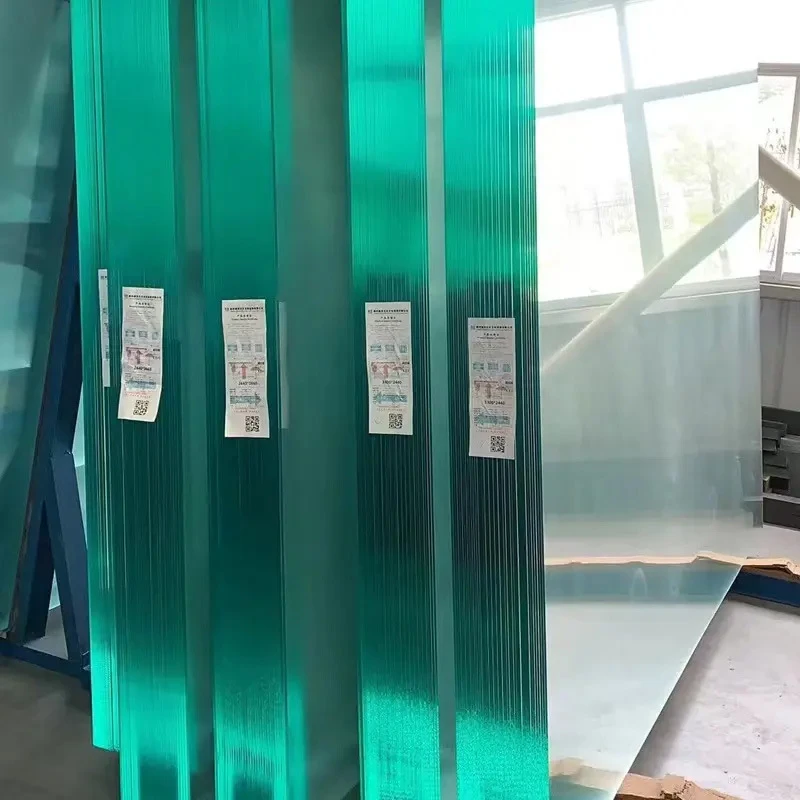

toughened glass material

Beyond products, the environmental advantage of utilizing toughened glass should be noted. It is fully recyclable, posing a sustainable option compared to many other materials. The recyclability not only decreases waste in landfills but also conserves the energy that would otherwise be used in manufacturing new glass, contributing positively to environmental conservation efforts.

The expertise involved in manufacturing and implementing toughened glass is extensive. Industry authorities continuously innovate and improve the tempering processes, ensuring the glass meets stringent safety standards and consumer expectations. Engineers and material scientists constantly research to enhance its properties further, making it more adaptable to future challenges.

Trust in toughened glass is fortified by its long-standing presence in safety applications worldwide. Consumers, product manufacturers, and regulatory bodies universally acknowledge its robustness and reliability. Detailed case studies and peer-reviewed research published by industry experts bolster its authoritative status and encourage widespread adoption.

The incorporation of toughened glass material reflects a commitment to quality and safety across industries. Its proven resilience, combined with an excellent track record in practical applications, makes it an indispensable component in numerous high-stress environments. As it continues to evolve, the trust and authority it commands are only predicted to grow, underpinning its crucial role in the future of material engineering.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu