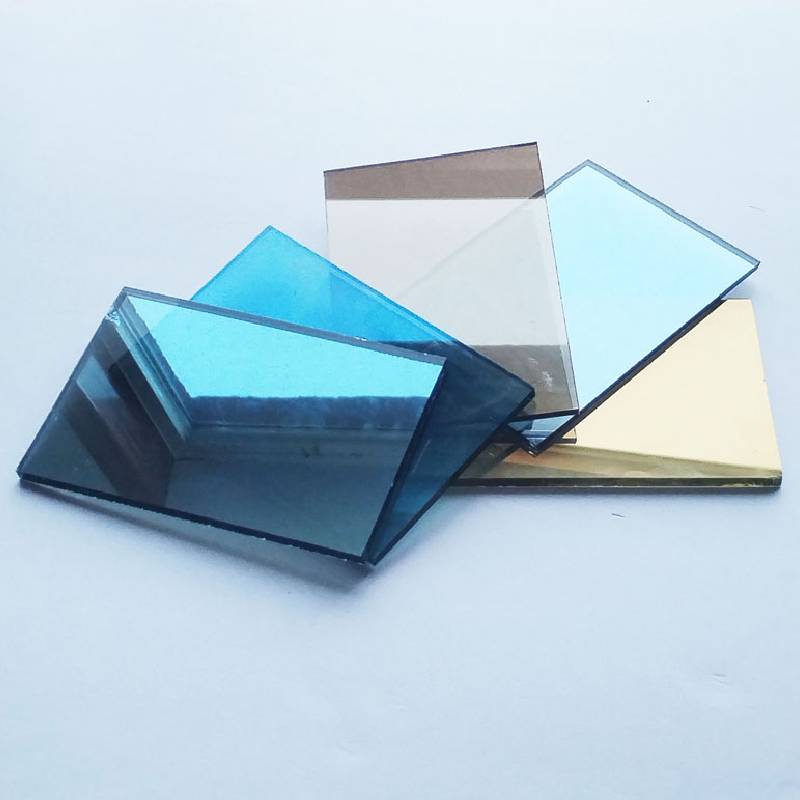

Type: light blue reflective glass, dark blue reflective glass, light green reflective glass (French green reflective glass), dark green reflective glass (emerald green reflective glass), brown reflective glass, bronze reflective glass, European gray reflective glass, dark Gray reflective glass, black reflective glass, gold reflective glass, silver reflective glass,

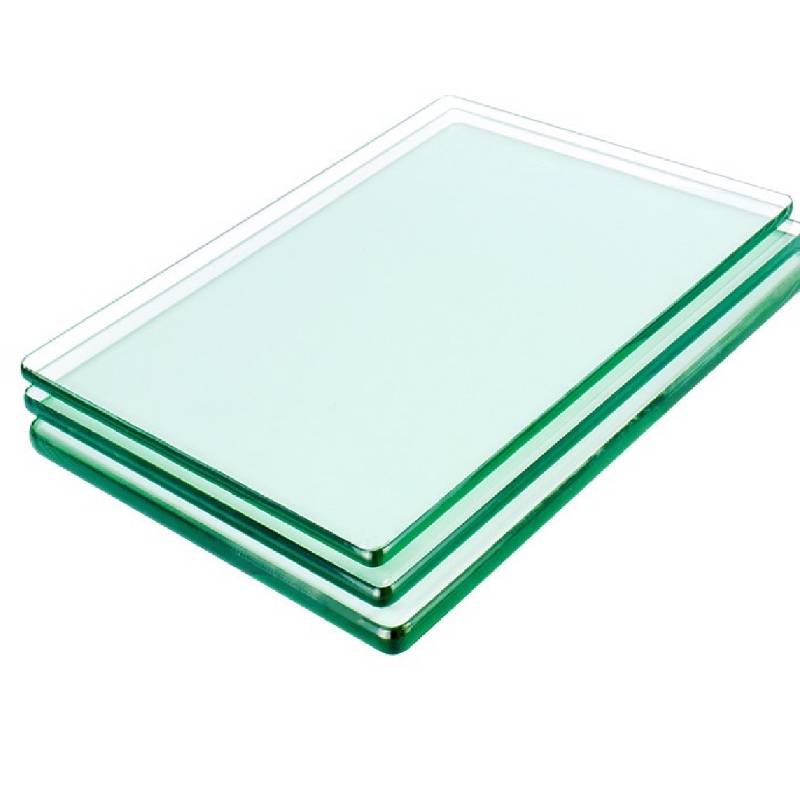

Thickness: 4mm, 5mm, 6mm.

Size: 1830*2440, 2140*3300, 2140*3660, 2140*1650, 2250*3300, 2250*3660, 2440*3660.

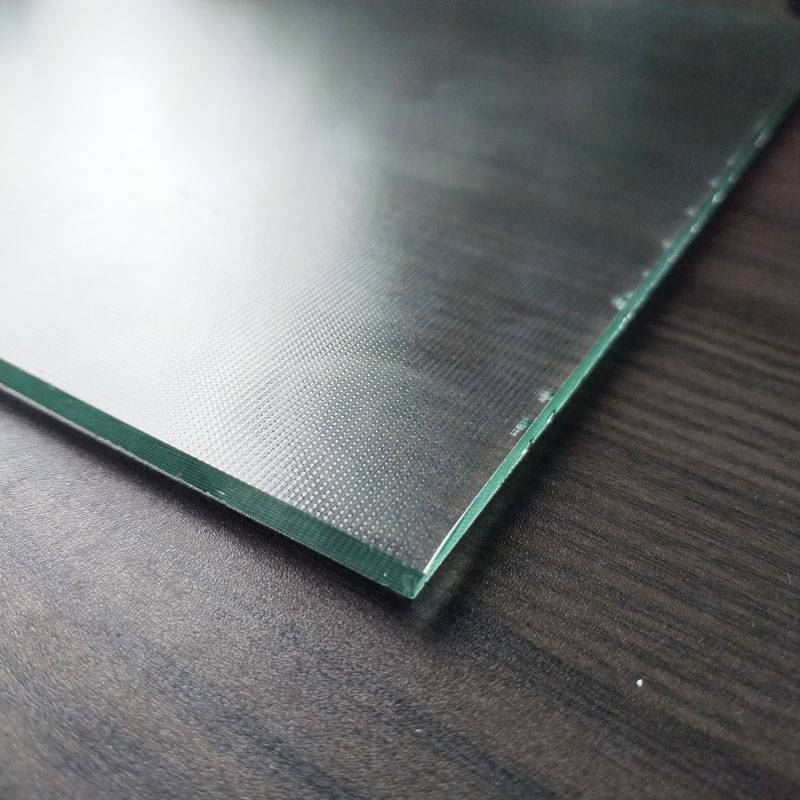

Color reflective glass is manufactured through a process known as vacuum sputtering or magnetron sputtering. This method involves depositing metallic oxides onto the surface of clear or tinted glass in a vacuum chamber. By controlling the composition and thickness of these metallic coatings, manufacturers can achieve a wide range of colors and reflective properties.

During the sputtering process, the glass substrate is placed in a vacuum chamber along with targets made of the desired metal oxides, such as titanium, zinc, or silicon. High-voltage electrical currents are then applied to the targets, causing atoms to be ejected and deposited onto the glass surface. The thickness and composition of these coatings determine the color and reflective characteristics of the glass.

Several parameters play a crucial role in determining the performance and appearance of color reflective glass:

- Visible Light Transmission (VLT): VLT refers to the percentage of visible light that passes through the glass. Different applications may require varying levels of VLT to control glare and brightness indoors.

- Solar Reflectance: This parameter measures the ability of the glass to reflect solar radiation, helping to reduce heat gain and energy consumption in buildings.

-

- U-Value: The U-value indicates the rate of heat transfer through the glass. Low U-values signify better insulation properties, contributing to energy efficiency in buildings.

-

- Color Rendering Index (CRI): CRI measures the ability of a light source to accurately reveal the colors of objects compared to natural light. High CRI values are desirable for applications where color fidelity is important, such as museums or retail spaces.

-

Color reflective glass finds applications across various sectors, thanks to its aesthetic appeal and functional properties:

- Architectural Facades: Reflective glass facades add a contemporary touch to buildings while improving energy efficiency by reducing solar heat gain. The reflective surfaces also create dynamic visual effects, especially in urban landscapes.

- Interior Design: In interior spaces, color reflective glass can be used for partitions, doors, and decorative elements to enhance natural light distribution and create visually striking environments.

- Automotive Industry: Reflective glass coatings are utilized in automotive windows to improve visibility, reduce glare, and enhance the overall appearance of vehicles. Additionally, they help regulate interior temperatures, improving comfort for passengers.

- Electronics: Color reflective glass is integral to the production of display panels for electronic devices such as smartphones, tablets, and televisions. The reflective coatings enhance screen clarity and color vibrancy, providing an optimal viewing experience for users.

- Solar Panels: Some variants of color reflective glass are engineered for use in photovoltaic solar panels, where they serve as protective layers while also optimizing light absorption for electricity generation.

Afrikaan

Afrikaan  Albaaniyaan

Albaaniyaan  Amxaari

Amxaari  Carabi

Carabi  Armeeniyaan

Armeeniyaan  Asarbayjaan

Asarbayjaan  Basque

Basque  Belarusiyaanka

Belarusiyaanka  Bengali

Bengali  Bosnia

Bosnia  Bulgaariya

Bulgaariya  Catalan

Catalan  Cebuano

Cebuano  Korsican

Korsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Ingiriis

Ingiriis  Esperanto

Esperanto  Istooniyaan

Istooniyaan  Finnish

Finnish  Faransiis

Faransiis  Frisian

Frisian  Galiciyan

Galiciyan  Joorjiyaan

Joorjiyaan  Jarmal

Jarmal  Giriig

Giriig  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawiye

hawiye  Cibraaniga

Cibraaniga  Maya

Maya  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  iriish

iriish  Talyaani

Talyaani  Jabbaan

Jabbaan  Javanese

Javanese  Kannada

Kannada  Kazakh

Kazakh  Khmer

Khmer  Ruwanda

Ruwanda  Kuuriyaan

Kuuriyaan  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Qaaxo

Qaaxo  Laatiinka

Laatiinka  Latvia

Latvia  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Masedooniyaan

Masedooniyaan  Malgashi

Malgashi  Malaay

Malaay  Malayalam

Malayalam  Malta

Malta  Maori

Maori  Marathi

Marathi  Mongoliyaan

Mongoliyaan  Myanmar

Myanmar  Nepali

Nepali  Noorwiiji

Noorwiiji  Noorwiiji

Noorwiiji  Occitan

Occitan  Pashto

Pashto  Faaris

Faaris  Polish

Polish  Boortaqiis

Boortaqiis  Punjabi

Punjabi  Romanian

Romanian  Ruush

Ruush  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Seerbiyaan

Seerbiyaan  Ingiriis

Ingiriis  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovakia

Slovakia  Islovenian

Islovenian  Somali

Somali  Isbaanish

Isbaanish  Sundanese

Sundanese  Sawaaxili

Sawaaxili  Iswidish

Iswidish  Tagalog

Tagalog  Taajik

Taajik  Tamil

Tamil  Tataarka

Tataarka  Telugu

Telugu  Thai

Thai  Turki

Turki  Turkmen

Turkmen  Yukreeniyaan

Yukreeniyaan  Urduu

Urduu  Uighur

Uighur  Uzbekistan

Uzbekistan  Vietnamese

Vietnamese  Welsh

Welsh  I caawi

I caawi  Yiddish

Yiddish  Yurub

Yurub  Zulu

Zulu