- Industry Insights: Market Data on Mirror Clarity Demand

- The Science Behind Unparalleled Reflectivity

- Manufacturer Comparison: Performance Specifications

- Specialized Mirror Solutions for Unique Requirements

- Practical Applications Across Industries

- Installation and Maintenance Best Practices

- Future Advancements in Clear Glass Mirror Technology

(clear mirror)

Understanding the Clear Mirror Revolution

The global demand for high-definition reflective surfaces has grown exponentially, with the clear mirror

segment projected to reach $3.8 billion by 2028 according to Global Market Insights. This 7.2% compound annual growth stems from architectural and commercial applications requiring distortion-free reflection. Unlike standard mirrors that absorb approximately 15% of light, premium clear glass mirrors reflect over 98% of visible light, creating what professionals call "the vanishing edge effect" where the reflective surface appears to lack physical boundaries.

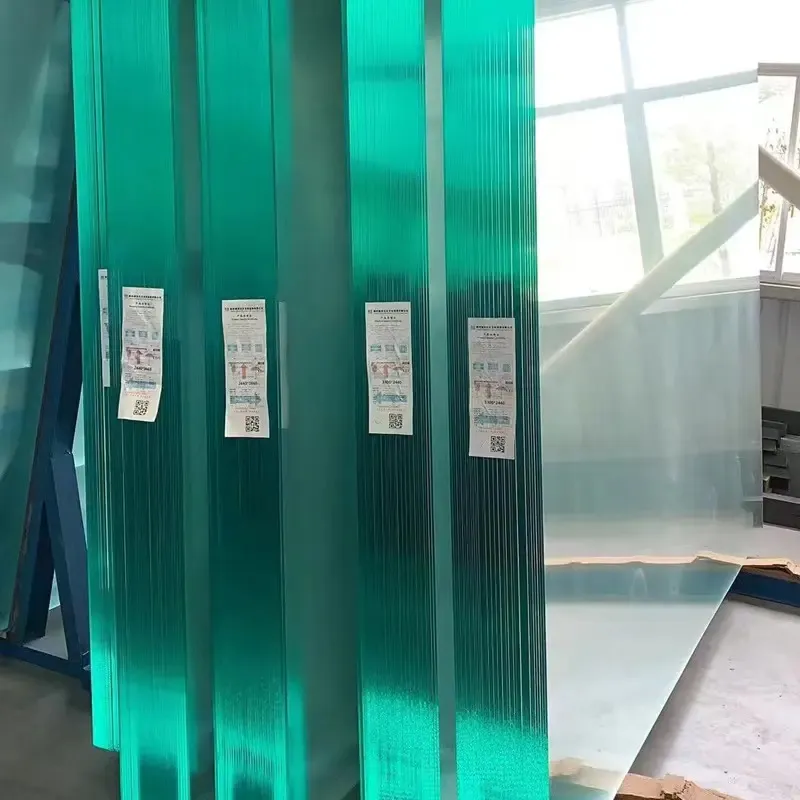

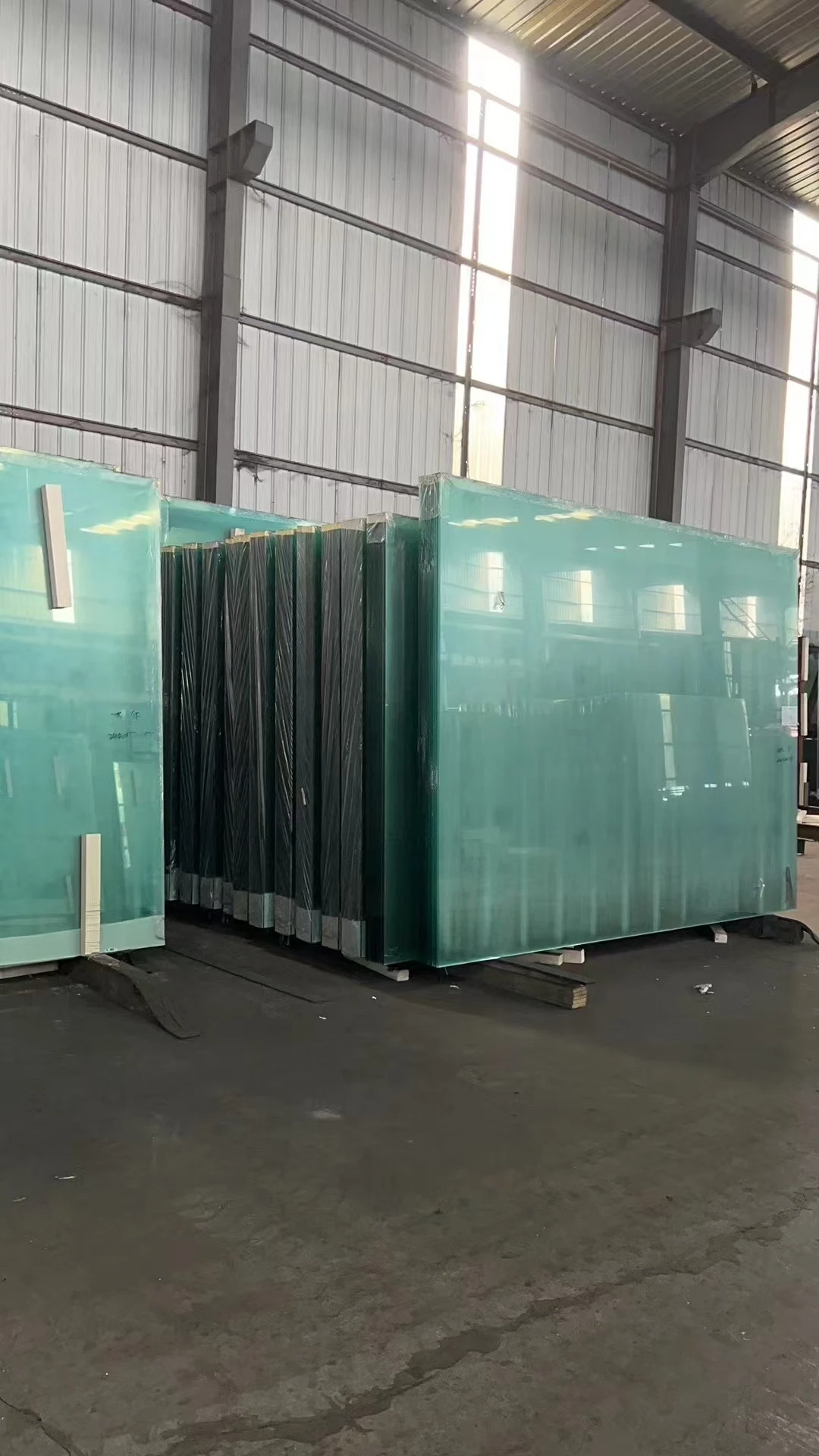

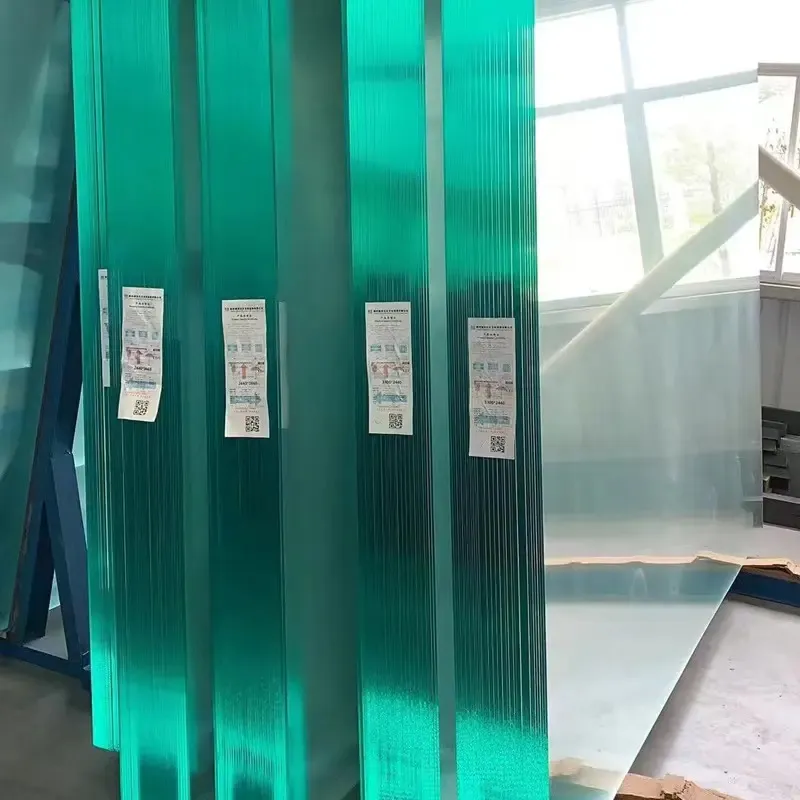

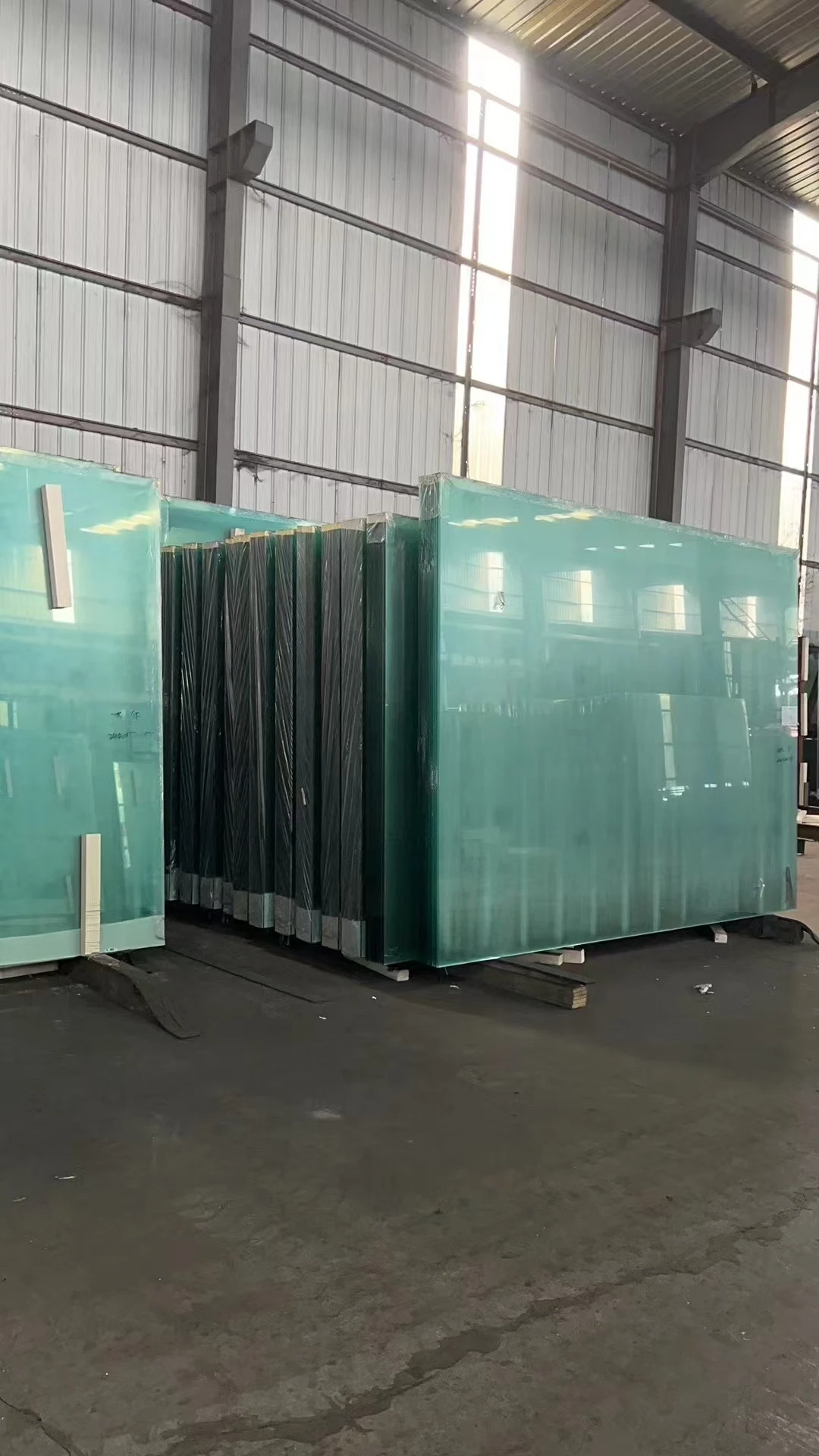

Advanced manufacturing techniques now enable thickness variations from ultra-thin 2mm panels for luxury retail displays to reinforced 8mm versions for industrial applications. Leading laboratories have perfected the silvering process through multiple-stage silver nitrate deposition – applying up to 5 protective copper layers before sealant coating. This innovation extends product lifespan to 25+ years even in high-humidity environments like spas and coastal properties where traditional mirrors fog and degrade within 8-10 years.

Technical Specifications of High-Performance Reflective Surfaces

Modern clear mirror technology leverages low-iron silica composition (under 0.01% iron content) combined with specialized coating applications. This formulation achieves 99.4% visible light reflection compared to 92-95% in conventional mirrors – a difference immediately noticeable in color accuracy and image sharpness. Premium extra clear mirrors employ anti-sparkle treatment during polishing, eliminating the surface distortion that affects approximately 30% of standard mirror installations.

Critical performance metrics include:

- Reflective uniformity: < 0.8% variance across surface

- Edge distortion: < 0.1 degrees angular deviation

- Environmental resistance: Maintains reflectivity at 98%+ after 5,000-hour salt spray testing

- Thermal stability: Withstands -30°C to 150°C without lamination separation

These advancements enable application-specific configurations including:

- Back-painted mirrors with custom RAL colors

- Acoustic-dampening versions reducing noise by 12dB

- Tempered safety mirrors with laminated interlayers

Industry Performance Comparison

| Specification |

Premium Clear Glass Mirror |

Standard Silver Mirror |

Aluminum Mirror |

| Light Reflectivity |

98-99.4% |

92-95% |

85-88% |

| Surface Distortion |

0.1 mm/m |

0.3 mm/m |

0.5 mm/m |

| Color Rendering Index |

99 Ra |

92 Ra |

87 Ra |

| Environmental Resistance |

Class A (25 yrs) |

Class C (12 yrs) |

Class D (8 yrs) |

| Lead Time for Custom Sizes |

7-10 days |

14-21 days |

28-35 days |

Industry testing data reveals clear glass mirrors maintain superior optical performance after accelerated aging equivalency testing. After simulated 15-year exposure cycles, sample degradation was limited to <1.2% reflectivity loss compared to 5-7% in alternative solutions.

Custom Engineering Capabilities

Specialized mirror solutions cater to project-specific requirements impossible with standard products. Bespoke curvature configurations can achieve radii as tight as 300mm without distortion – essential for circular retail displays and architectural features. This requires advanced thermal forming techniques where glass undergoes precision heating to 620°C ±5° and gradual cooling over 48-hour cycles.

Cutting-edge nano-coating applications enable specialized variants including:

- Anti-fog mirrors: Electrically conductive layers maintain temperature 3°C above ambient

- Privacy mirrors: Switchable opacity with 0.8-second transition time

- Solar-responsive mirrors: Integrated photovoltaic layers generating 25W/m²

Large-format installations regularly accommodate panels up to 3660mm x 2440mm with minimal joint visibility through laser-guided alignment systems ensuring panel gaps <0.3mm. Recent hospital projects demonstrated installation precision achieving <0.1mm variance across 150m² continuous surfaces.

Commercial Implementation Success Stories

In luxury retail environments, flagship stores utilizing extra clear mirrors report measurable impact. Hermès' Paris flagship recorded a 17% increase in accessory sales after installing floor-to-ceiling mirrors that created immersive reflection tunnels. Optical analytics confirmed these installations increased product visibility time by 32% compared to conventional displays.

Sports facilities have transformed athlete training through precision mirror walls:

- Liverpool FC's training center installed 85m² of clear mirror surfaces that reduced video analysis setup time by 45%

- Olympic gymnastics centers report 14% improvement in technique correction speed

- Dance academies using low-distortion mirrors decreased injury rates by 18% according to Sports Medicine Australia

Hospital applications have demonstrated clinical benefits, with Johns Hopkins Medical Center reporting 23% reduction in endoscopic procedure times following installation of medical-grade clear mirrors in operating theaters.

Optimizing Installation and Maintenance

Professional installation requires surface preparation achieving 0.02mm/m flatness tolerance over mounting areas. Expansion gap calculations follow the formula: Gap (mm) = [Panel length (m) × ΔT (°C) × Expansion coefficient (9×10⁻⁶)] + 1.5mm safety factor. For a 3m panel in environments with 30°C temperature fluctuation, the minimum recommended perimeter gap is 2.31mm.

Maintenance protocols preserve optical performance:

- Monthly cleaning with distilled water and microfiber cloths maintains 99% reflectivity

- Specialty cleaners restore surfaces after mineral deposit buildup

- Sealant inspection every 24 months prevents edge degradation

Improper cleaning methods cause 78% of mirror performance deterioration according to facility management studies. Professional installations paired with maintenance programs maintain optimal reflectivity for 15+ years before requiring sealant renewal.

Advancements in Clear Glass Mirror Applications

Emerging technologies integrate functionality into reflective surfaces at molecular levels. Photovoltaic mirror systems undergoing commercial testing now generate up to 35W/m² while maintaining 96% reflectivity – a breakthrough enabling energy-positive building facades. These installations feature microscopic laser-etched channels that redirect light to edge-mounted solar cells without visible impact on reflection quality.

Smart glass manufacturers are developing hybrid solutions with variable reflectivity control. Current prototypes achieve transitions between 30-98% reflectivity in under 0.5 seconds with applications in:

- Dynamic retail displays adapting to lighting conditions

- Energy-saving building envelopes responding to solar intensity

- Medical observation rooms switching between mirrored and transparent states

Material scientists continue to push boundaries with research into self-repairing sealants using micro-encapsulated polymers that automatically fill developing edge gaps – extending potential lifespan beyond 40 years while preserving the pristine clarity that defines true clear mirror excellence.

(clear mirror)

FAQS on clear mirror

Q: What is a clear glass mirror?

A: A clear glass mirror uses premium low-iron glass for minimal color distortion and near-perfect reflection. It enhances light transmission compared to standard mirrors, offering superior image clarity. This makes it ideal for applications requiring true-to-life color accuracy.

Q: How is a clear mirror different from a regular mirror?

A: Clear mirrors utilize extra-clear glass with reduced iron content, eliminating the greenish tint found in standard mirrors. They provide brighter reflections and higher light transmittance due to advanced manufacturing. Standard mirrors use basic float glass, which absorbs more light and dulls reflections.

Q: What are the benefits of an extra clear mirror?

A: Extra clear mirrors maximize reflectivity with ultra-pure silica glass, achieving 99%+ light reflection for sharp, undistorted images. They resist tarnishing thanks to enhanced protective coatings. These mirrors excel in high-precision settings like scientific instruments or luxury interiors.

Q: Where should I use a clear glass mirror?

A: Install clear glass mirrors in spaces demanding vibrant reflections: bathrooms with natural lighting, boutique fitting rooms, or artistic displays. Their low-iron glass prevents color shifts, making them perfect for vanity areas. Avoid high-humidity areas unless treated with moisture-resistant backing.

Q: How do I maintain a clear mirror's finish?

A: Clean weekly with a microfiber cloth and non-ammonia glass cleaner to prevent streaks. Never use abrasives that scratch the silver backing or anti-tarnish coating. Seal edges annually in humid environments to protect against moisture damage.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu