Cutting toughened safety glass is not just about technical expertise; it's a meticulous process requiring precise knowledge and a robust understanding of glass properties. Toughened safety glass, known for its strength and durability, presents unique challenges that differentiate it from standard glass cutting practices.

Here’s an insider view into the complex world of handling toughened safety glass.

Toughened safety glass undergoes a thermal tempering process which significantly increases its strength compared to regular glass. The heating and rapid cooling procedure causes the outer surfaces to be compressed and the inner surfaces to be under tension. This process bestows upon the glass its safety features, causing it to shatter into small granular chunks instead of sharp shards when broken. This characteristic is a double-edged sword when it comes to cutting, as any attempt to cut toughened glass after it has been tempered will result in it shattering, thus making traditional glass cutting methods ineffective.

Given these challenges, cutting must be approached with pre-planned precision. The cutting of toughened glass must occur prior to the tempering process. Therefore, the first step in handling such material is measurement and marking, a procedure that must be performed with acute precision. Mistakes at this stage are irreversible and costly, emphasizing the necessity for accuracy.

For anyone dealing with toughened safety glass, the importance of specialized equipment cannot be overstated. A glass scorer, often equipped with a diamond-tipped blade, is essential for making the initial scores. These tools require careful handling and a steady hand to ensure that the lines are straight and true. Following the scoring, a controlled snapping process is utilized to split the glass along the scored line. Unlike cutting, this is more of a controlled fracture, and it demands both patience and expertise.

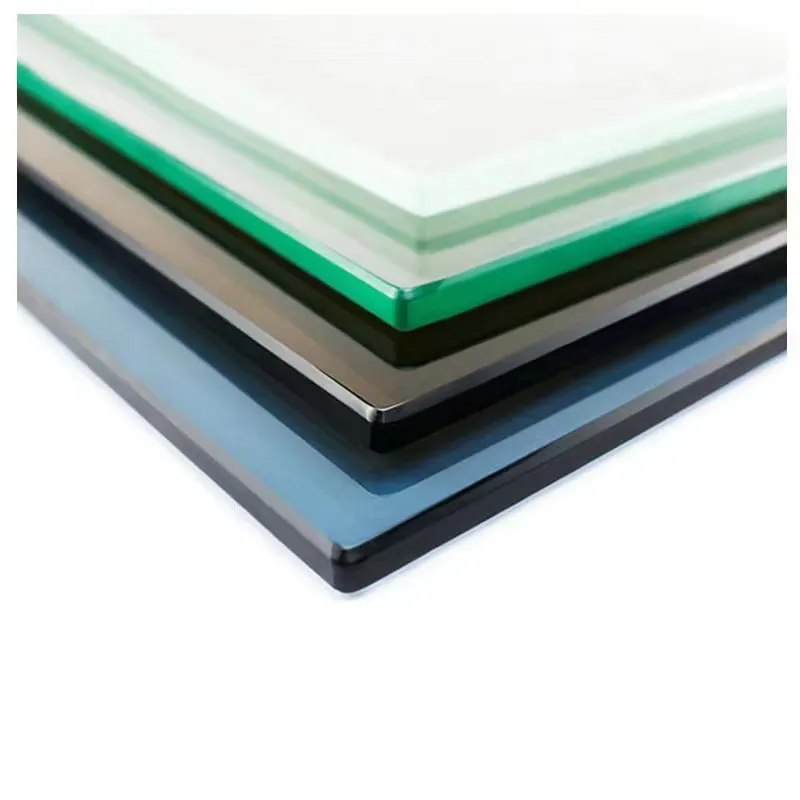

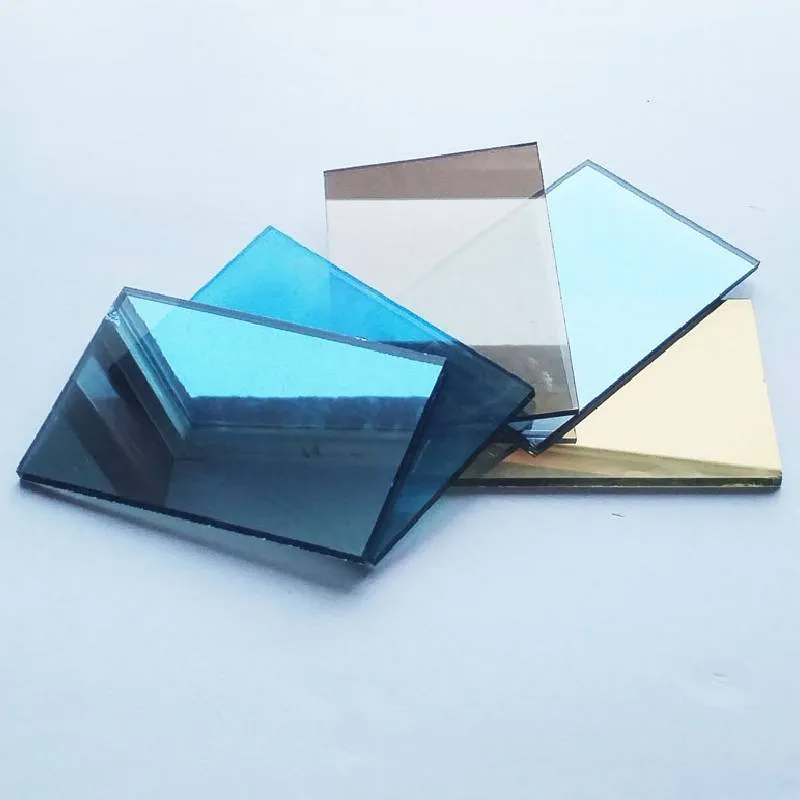

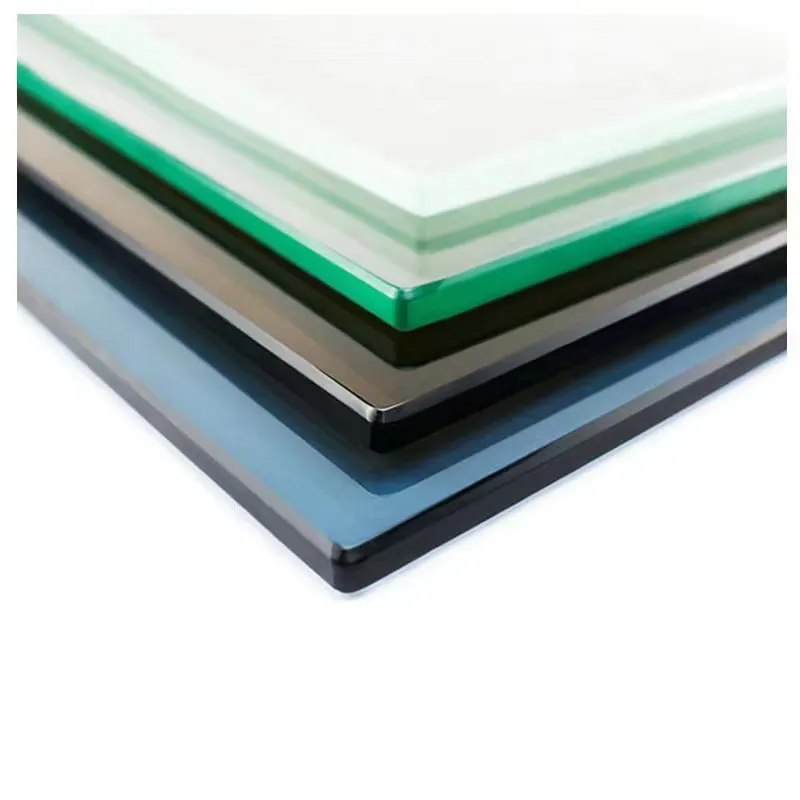

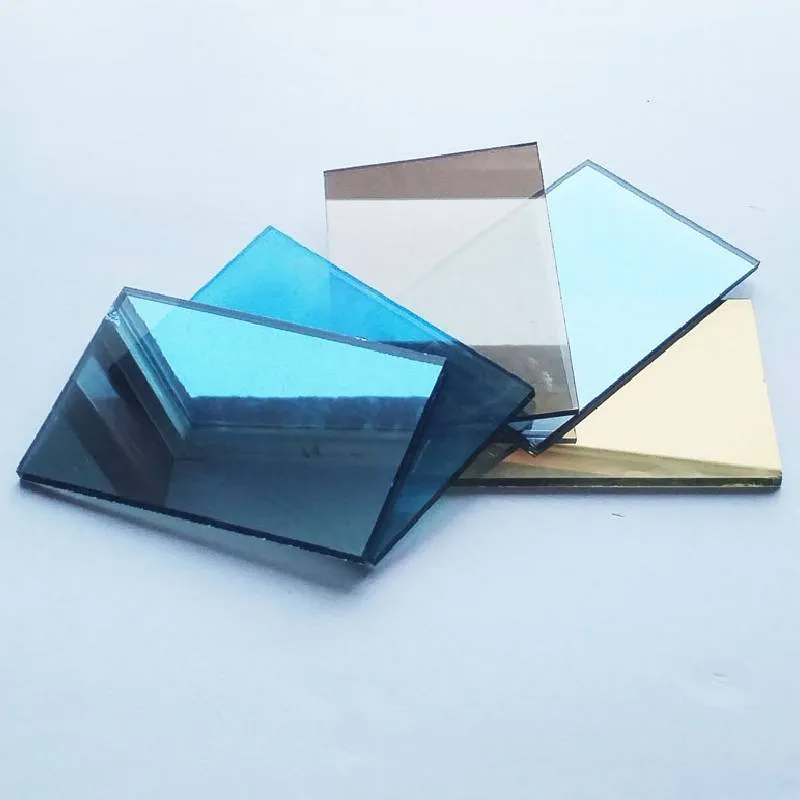

Consultation with industry experts highlights the importance of selecting high-quality materials. Only raw glass that meets rigorous industry standards should be chosen for projects involving tempering. This ensures that once the glass is cut, shaped, and subsequently tempered, it retains its safety qualities and aesthetic precision.

cutting toughened safety glass

Toughened safety glass is best suited for applications where safety, durability, and resistance to thermal shock are paramount. It is commonly used in high-traffic areas, such as glass doors, shower screens, and facades. However, the utility of toughened glass extends beyond obvious applications. With appropriate cutting and tempering, it can be used innovatively in interior design, providing a modern touch to office spaces and homes alike.

For professionals engaged in cutting this type of glass, continuous education and training are indispensable. Craftsmanship in glass cutting is both an art and a science. It's recommended to stay updated on the latest technological advancements and industry practices to ensure top performance.

Safety remains a critical consideration throughout the cutting and tempering processes. Protective gear, such as safety goggles and cut-resistant gloves, should be a standard part of any glassworker’s toolkit. Equally important is adherence to prescribed safety protocols, which safeguard not only the glassworker’s wellbeing but also the integrity of the glass.

Industry regulations and standards play a crucial role in maintaining quality and safety. Familiarity with local and international standards ensures compliance, which is vital for both legal and safety reasons. Moreover, collaborating with suppliers who adhere to these standards also enhances credibility and trustworthiness.

In conclusion, cutting toughened safety glass requires more than just technical skill—it's an endeavor that demands rigorous planning, exactitude, and unwavering compliance with safety standards. By emphasizing the importance of pre-cutting accuracy, utilizing specialized tools, and adhering to industry regulations, businesses can effectively cater to the increasing demand for this durable and safety-oriented glass product. With proper preparation and skill, toughened safety glass can be tailored to meet varied customer needs, setting a high bar for both functional and aesthetic applications. Through dedication to expertise, practitioners not only improve their craft but also fortify their standing as authoritative and trusted leaders in the glass industry.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu