The demand for **tempered glass** — also known as toughened glass — continues to rise across sectors including construction, automotive, electronics, and industrial applications. To make informed decisions about procurement and specification, it’s crucial for professionals to understand both the latest tempered glass price trends and the technical factors affecting cost, quality, and performance. This article provides an in-depth analysis, focusing on the top-grade Clear float flat tempered glass, complete with technical data, manufacturing process, comparative industry insights, and practical case studies.

↑ 14.8%

Global tempered glass market CAGR (2022-2029)

(Source: Mordor Intelligence)

$27.5 Bn

Market size in 2023

10mm

Top-selling specification for heavy-duty architectural use

1. Tempered Glass vs. Toughened Glass Price: 2024 Market Overview

Both “tempered glass” and “toughened glass” refer to the same thermal processing technology, producing glass that is up to 5 times stronger than standard annealed glass. With surging infrastructure projects and safety requirements, international tempered glass price indices show a consistently upward trend, notably for large custom sheets (custom tempered glass) and high-thickness options like 10mm toughened glass. China, India, and Southeast Asia lead production, with technology advances narrowing regional price gaps, but certifications, raw material costs, and energy prices still contribute to price differentials.

Tempered/Toughened Glass Price Comparison by Region & Specification (2024, USD/square meter)

| Product Type |

China |

Europe |

USA |

Middle East |

| 6mm Tempered Glass |

$7-11 |

$18-26 |

$22-30 |

$13-18 |

| 10mm Toughened Glass |

$13-20 |

$32-42 |

$35-50 |

$21-28 |

| Custom Tempered Glass |

+8% (spec. dependent) |

+15% (min. order) |

+18% (shape/silkprint) |

+10% (laminated) |

*Prices are FOB, source: World Glass Index, Q2 2024

Market trends are reflected in price differences by region and thickness.

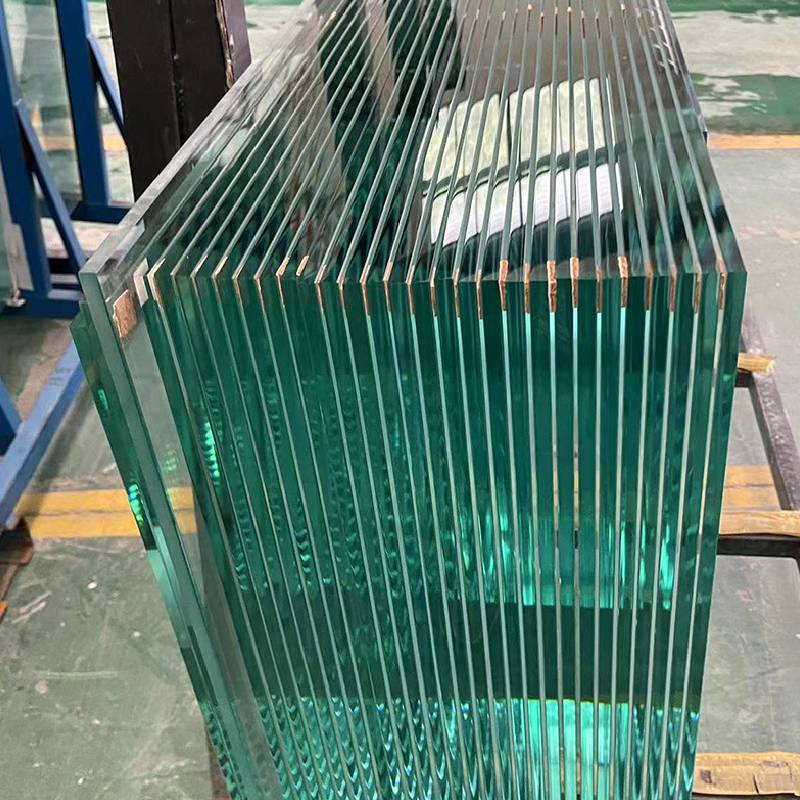

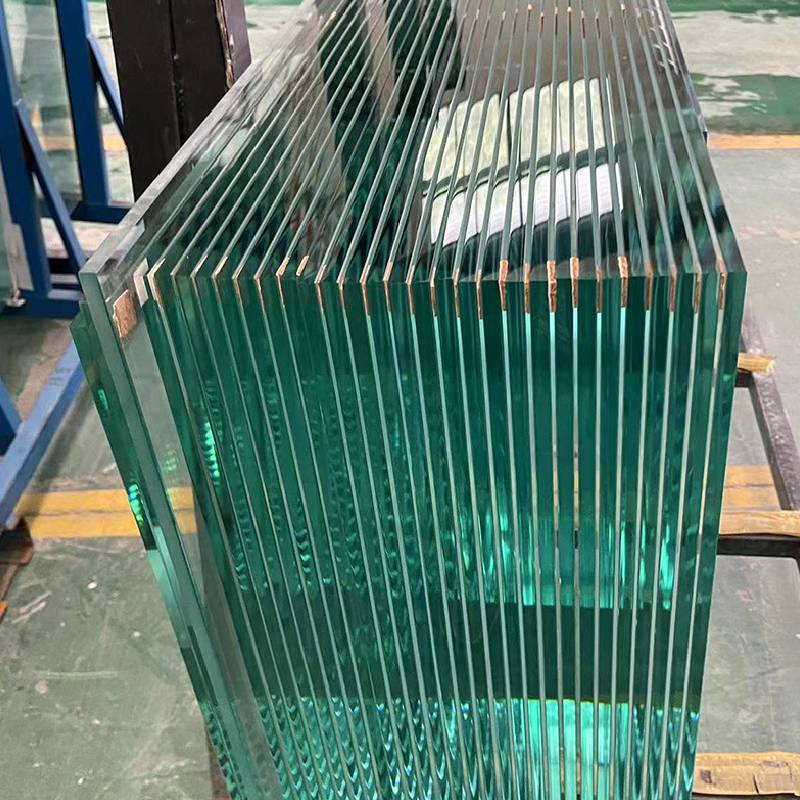

2. Process Flow: Clear Float Flat Tempered Glass Manufacturing

The Clear float flat tempered glass manufacturing process integrates advanced float glass and tempering technology to ensure outstanding strength, transparency, and safety. Here is a stepwise technical overview for those evaluating **tempered glass price** and quality:

Raw Material Melting

Silica sand, soda ash, and lime are melted at 1550°C.

(Ensures clarity & purity of base glass)

Float Process

Molten glass floats on molten tin, forming a uniform flat sheet with precise thickness.

CNC Cutting/Shaping

Automated CNC machines cut to required size/shape with edge polishing for safety compliance (EN12150).

Thermal Tempering

Sheets rapidly heat to ~650°C, then air-quenched, producing compressive surface stress & 5x strength.

(ANSI Z97.1, ISO 12543 standards)

Quality Inspection

ISO/EN/SGS/FDA testing: Fragmentation, flatness, surface flaw, and optical clarity checks.

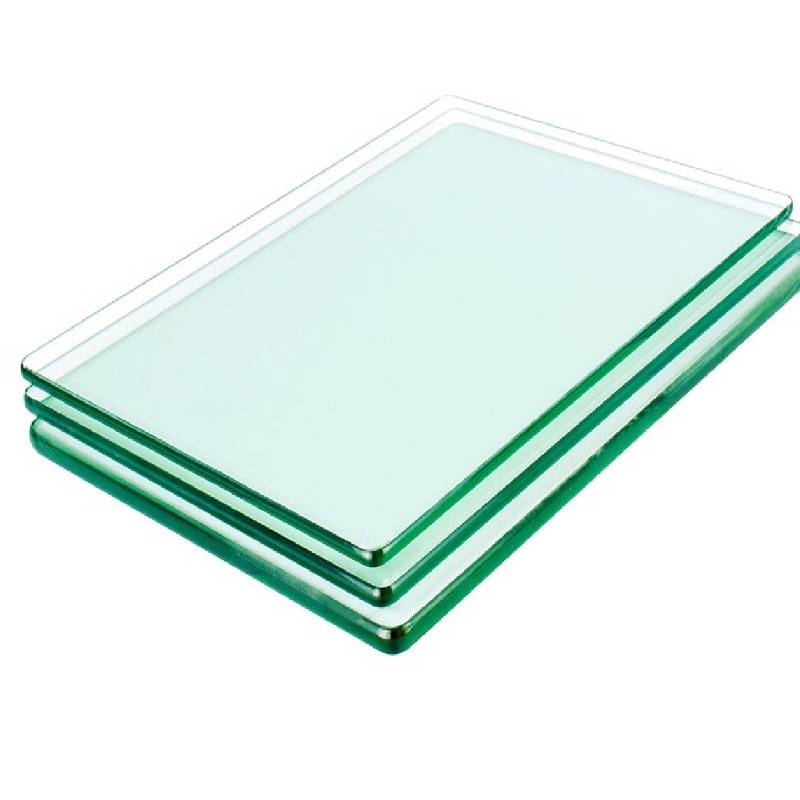

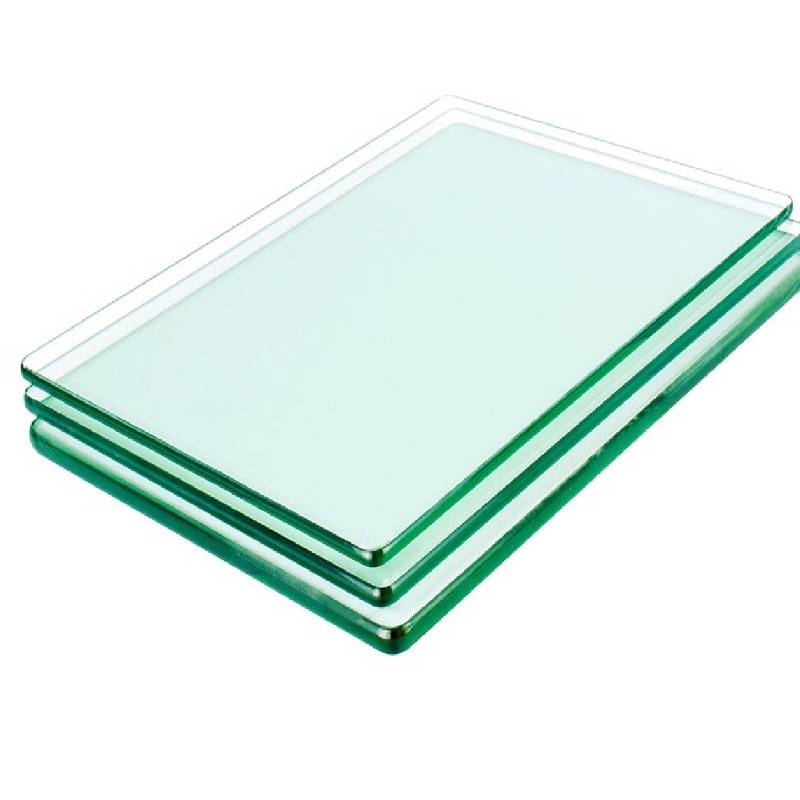

Process flow shown for Clear float flat tempered glass.

[See video]

Automated lines for float glass tempering ensure efficiency and consistency.

3. Product Parameters: Clear Float Flat Tempered Glass

When considering tempered glass price, it is essential to compare not only the cost but also the product’s physical and mechanical parameters. Below is an outline of technical properties and standards achieved by Clear float flat tempered glass:

| Parameter |

Clear Float Flat Tempered Glass |

Standard Annealed Glass |

Compliance/Standard |

| Available Thickness (mm) |

4 / 5 / 6 / 8 / 10 / 12 / 15 / 19 |

4–19 |

EN 572, ISO 12543 |

| Max Size (mm) |

3300 × 12000 |

2440 × 3660 |

Custom |

| Bending Strength |

≥120Mpa |

30–45Mpa |

BS 6206: Class A |

| Surface Flaw Count |

< 0.3/m² |

1.5/m² |

GB 15763.2-2005 |

| Light Transmittance (%) |

89% (6–10mm) |

85% |

ISO 9050 |

| Thermal Performance |

Temp. resistance: > 250°C |

130°C |

ANSI Z97.1 |

| Fragmentation Test |

Safe small particles (<40mm2) |

Large/Irregular shapes |

EN 12600: 1(C)2 |

| Warranty |

10 years |

5 years |

Manufacturer |

Data based on 2024 manufacturer test reports and ISO/ANSI/EN standards.

Clear float flat tempered glass outperforms in strength, size, and optical clarity.

4. Manufacturer Comparison: Major International Producers

| Brand / Country |

Product Type |

Main Certifications |

Typical Applications |

Toughened Glass Price (USD/m²) |

| Saint-Gobain (France) |

SGG SECURIT |

EN 12150, ISO 12543, ASTM C1048 |

Facade, Automotive, Interior |

$43-52 |

| NSG Pilkington (UK/Japan) |

Toughened Safety Glass |

BS 6206, ISO 9001 |

Railways, Aviation, Electronics |

$40-48 |

| Guardian Industries (USA) |

Guardian UltraClear® |

ANSI Z97.1, CPSC 16 CFR 1201 |

Storefront, Premium Display |

$48-56 |

| SHZR Glass (China) |

Clear Float Flat Tempered Glass |

ISO 9001, EN 12150, SGS, CE |

Architecture, Machine Enclosures |

$13-20 |

| AGC (Japan/Global) |

Laminated Toughened Glass |

JIS R3206, ISO 12543 |

Security, Soundproofing |

$45-58 |

5. Custom Tempered Glass Solutions — When and Why?

- Shape and Size: CNC cutting enables complex shapes for architectural features, machine windows, elevator walls, and more.

- Silkscreen Printing & Low-E Coatings: Custom branding, privacy areas, and energy efficiency.

- Extra-clear Glass: For ultra-transparent walls, aquariums, laboratories, and retail showcases.

- Double/Triple Tempering: For ballistic, blast-resistant, or thermal facade systems.

- UV, Anti-glare, Frosted Surfaces: For special visual or optical needs.

Custom tempered glass applied in an oil refinery's safety barriers.

6. Technical Advantages of Clear Float Flat Tempered Glass

- Outstanding Safety: Fragmentation creates safe small pieces to minimize injury risk (see EN 12600 test results).

- Superior Mechanical Strength: Withstand high wind loads, thermal shock and heavy impact (≥120MPa bending strength).

- Wide Range of Dimensions: Stat-of-the-art float lines support panels up to 3.3 x 12 meters.

- Chemical Resistance: Suitable for harsh petrochemical, laboratory, and coastal environments.

- Sustainability: Meets LEED credits & supports green building with high light transmittance and potential for recycling.

- Long Service Life: Verified for 20+ years under outdoor/industrial application via EN, ISO accelerated aging standards.

7. Typical Application Scenarios and Case Studies

- Petrochemical Plants: Control room enclosures, explosion-resistant barriers with custom tempered glass.

- Metallurgy Sector: High-temperature windows, process monitoring panels.

- Infrastructure & Waterworks: Transparent covers and partitions for safety and process visibility.

- High-rise Facades: 10mm toughened glass commonly specified for wind-load safety and post-breakage integrity.

- Public Transport: Bus stops, stations, railway windows demanding vandal resistance.

Case Example: South-East Asia Airport Terminal selected 10mm Clear float flat tempered glass for facade and internal partitions. Performance testing under ISO 16932 confirmed over 120MPa flexural strength and passed all ECE R43 impact tests, while price was 17% lower than European imports. Maintenance after 3 years showed no visible corrosion or optical degradation.

Customer Testimonial: “The combination of safety, energy efficiency, and competitive tempered glass price from SHZR Glass made the decision easy for our EPC team.” — Global Facilities Manager, Top 100 ENR Contractor

8. FAQ on Tempered Glass Material, Specification, Standards, and More

Q1. What is the base material of clear float flat tempered glass?

A1: It’s produced from high-grade silica sand, soda ash, and dolomite, melted and floated to ensure purity and flatness before tempering.

Q2. What sizes and thickness are available for industrial use?

A2: Standard thickness ranges: 4mm, 6mm, 8mm, 10mm toughened glass, 12mm, and up to 19mm. Max panel size: 3300mm × 12000mm, supports custom CNC shapes.

Q3. Which international standards does your tempered glass meet?

A3: Complies with EN 12150 (Europe), ANSI Z97.1 (US), ISO 12543 (global), and optional SGS/CE/SGCC marking.

Q4. How is quality of each sheet tested?

A4: Each sheet undergoes optical inspection, stress tests, UV transmittance and fragmentation testing in accordance with EN/ISO standards. All quality data are logged and traceable.

Q5. What kind of edge and corner finishing is provided?

A5: CNC-polished edges (flat, pencil, arris, C-edge), safety radius corners; custom holes/cut-outs as per installation standard and drawing.

Q6. What is the lead time for custom tempered glass orders?

A6: Typical delivery cycle is 6–12 days for standard specs, 14–21 days for custom or oversized panels (ex-works or FOB, with online order-tracking).

Q7. Does tempered glass have a warranty and after-sales support?

A7: Yes, all shipments have a 10-year structural warranty, 24/7 technical support, and real-time claims portal. Certificates available upon request.

9. Delivery, Warranty & Customer Service Commitments

- Delivery Terms: EXW/FOB/CFR/CIF available. On-site inspection and video verification for OEMs.

- Lead Time: Standard: 6–12 days. Large custom orders: 14–21 days.

- Warranty: 10 years against delamination, breakage (under installation spec). Certificate upon request.

- Support: 24/7 hotline, multi-language tech team, compliance documentation (ISO/SGS/CE).

10. References and Industry Sources

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu