The float glass manufacturing process stands as a pivotal innovation in the architectural and automotive industries, renowned for its ability to produce uniform and clear flat glass. With roots tracing back to the mid-20th century, the process has become both an art and a science, requiring precise expertise and mastery of technological advances to meet contemporary demands for quality and efficiency.

Understanding the intricacies of float glass manufacturing begins with the raw materials. A blend primarily consisting of silica sand, soda ash, lime, dolomite, and various other components such as alumina, is carefully combined. Each material plays a specific role—silica provides the necessary network for the glass, soda ash reduces the melting temperature, and lime contributes to the chemical durability of the final product.

The journey of creating float glass starts in the furnace, where the raw material mix is gradually melted at approximately 1700 degrees Celsius. This is a critical step in the process, requiring deep understanding and control to ensure the melt is homogenous. Any deviation during this stage can lead to imperfections in the float glass, underscoring the necessity for expertise in furnace operations.

Once the molten glass reaches the desired molten state, it is guided onto a bath of molten tin, an ingenious innovation that ensures the glass achieves a perfectly flat and uniform surface. This stage of the process highlights the artful balance between gravity and surface tension, attributes that need continual monitoring and adjustments. Operators skilled in observing the qualities of the flowing glass make precise changes, maintaining the sheet’s thickness and surface quality.

As the glass floats along the tin bath, it gradually cools under controlled conditions. This cooling phase is vital, dictating the internal stresses, optical clarity, and mechanical strength of the final product. With an understanding rooted in experience, operators can anticipate and adjust for variations that could impact the final glass quality, ensuring consistency that meets stringent industry standards.

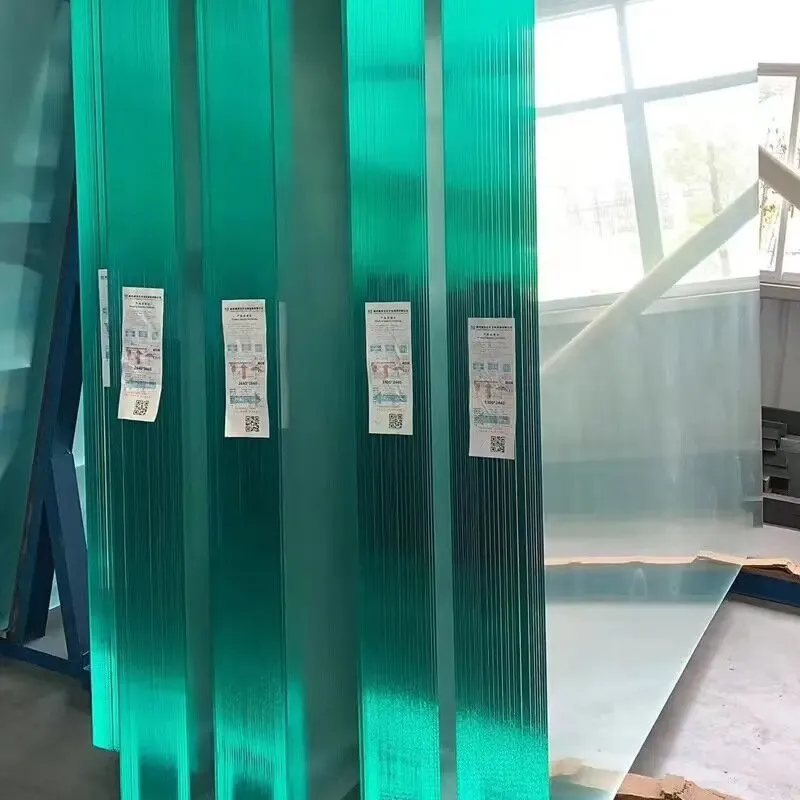

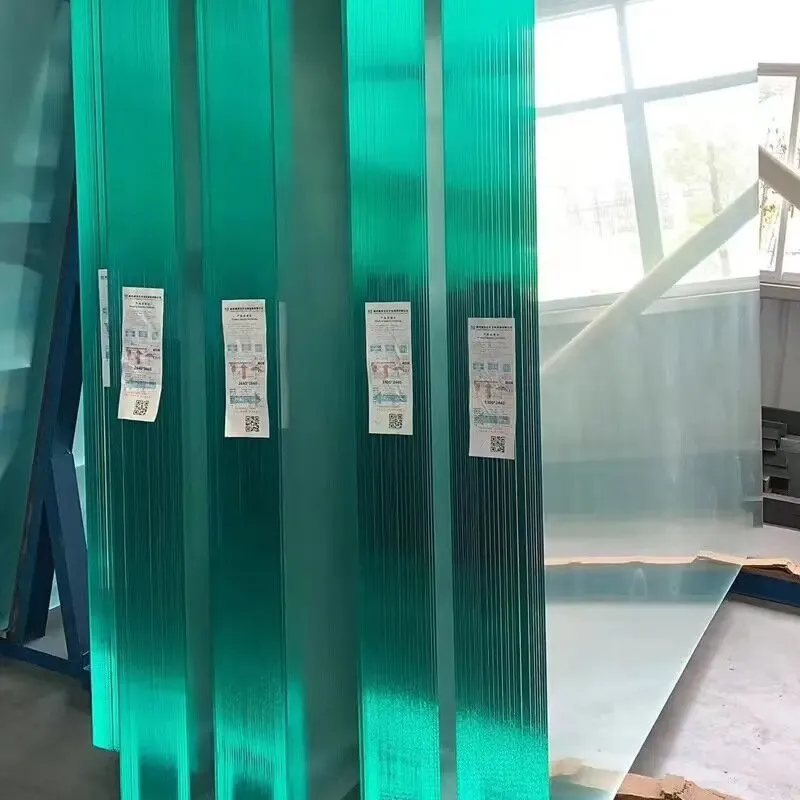

float glass manufacturing process

Following the float bath, the glass enters an annealing lehr. This elongated oven is where the glass is slowly cooled through a series of controlled temperature zones to relieve the internal stresses introduced during the manufacturing process. Expertise in this phase is essential; it determines the glass's durability and its suitability for subsequent cutting, polishing, and further processing.

Upon exiting the annealing lehr, the float glass undergoes rigorous inspection. Advanced technologies, such as automated optical scanners, detect defects invisible to the naked eye. This meticulous inspection process ensures that only glass of the highest quality proceeds to the market, reflecting the authority of manufacturers in delivering reliable and premium products.

One of the critical advantages of float glass is its versatility. From clear and tinted to coated and treated variants, it finds application in a variety of products, including windows, mirrors, and solar panels. The ability to produce such diverse products from a single process illustrates the operational excellence and trustworthiness developed over decades within the industry.

Manufacturers continually invest in research and development to optimize the float glass process, incorporating sustainable practices such as recycling cullet (crushed glass) back into the furnace, reducing energy consumption, and lowering emissions. Such advances are not only environmentally responsible but also economically advantageous, ensuring the long-term sustainability and competitiveness of the industry.

In conclusion, the float glass manufacturing process is a testament to human ingenuity and industrial craftsmanship. Mastery of this process requires a commitment to excellence and a deep understanding of the interplay between technology, materials, and human skills. As the architectural and automotive industries evolve, the demand for high-quality float glass will continue to grow, bolstered by ongoing innovations and the unwavering dedication of professionals committed to advancing the art of glassmaking.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu