- 1. Raw material selection: The process starts with the selection of high-quality raw materials, usually silica sand, soda ash and limestone. These materials were chosen for their purity and consistency, as they greatly influence the final quality of the glass.

2. Ingredients: The selected raw materials are accurately weighed and mixed together in specific proportions. This mixture, called a batch, is loaded into a furnace and melted.

3. Melting: The batch is fed into a furnace that is heated to extremely high temperatures, typically between 1,500 and 1,700 degrees Celsius (2,732 and 3,092 degrees Fahrenheit), depending on the type of glass being produced. Intense heat melts the batch into a viscous liquid called molten glass.

4. Shaping: Once the molten glass reaches the desired consistency, it is formed into the desired shape. This can be done by various methods such as blowing, pressing or moulding. For Moru glass, which often has intricate patterns, techniques such as glass blowing or hand shaping can be used to achieve the desired design.

6. Annealing: Newly formed glass undergoes a process called annealing to eliminate internal stress and strengthen the glass. This involves gradually cooling the glass at a controlled rate to ensure an even temperature distribution throughout the material.

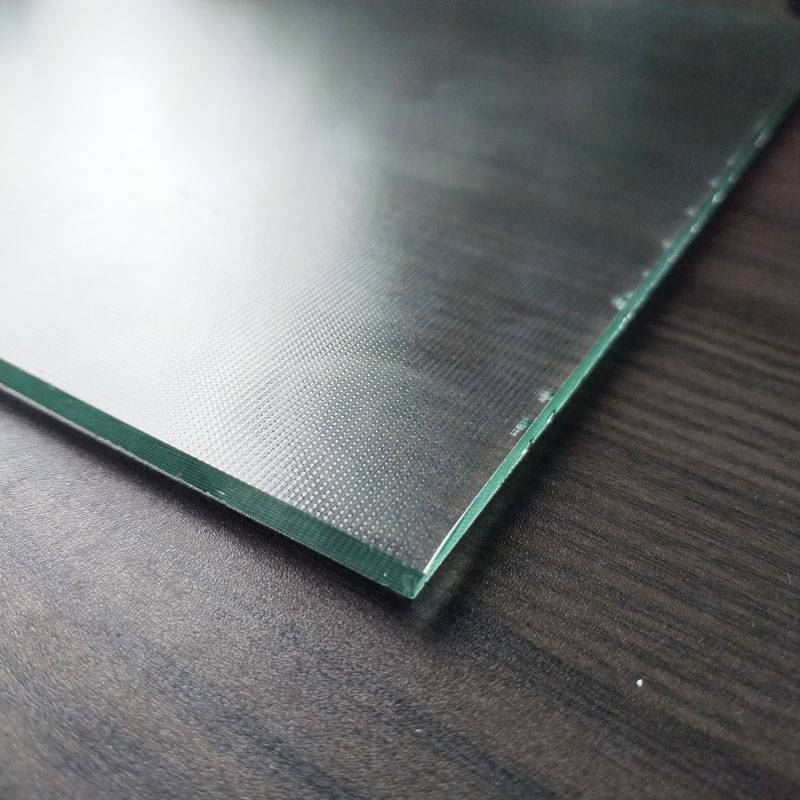

7. Finishing: After annealing is complete, inspect the glass for any defects or blemishes. Any rough edges or sharp points are smoothed away, and the final product is cleaned and polished to enhance its appearance.

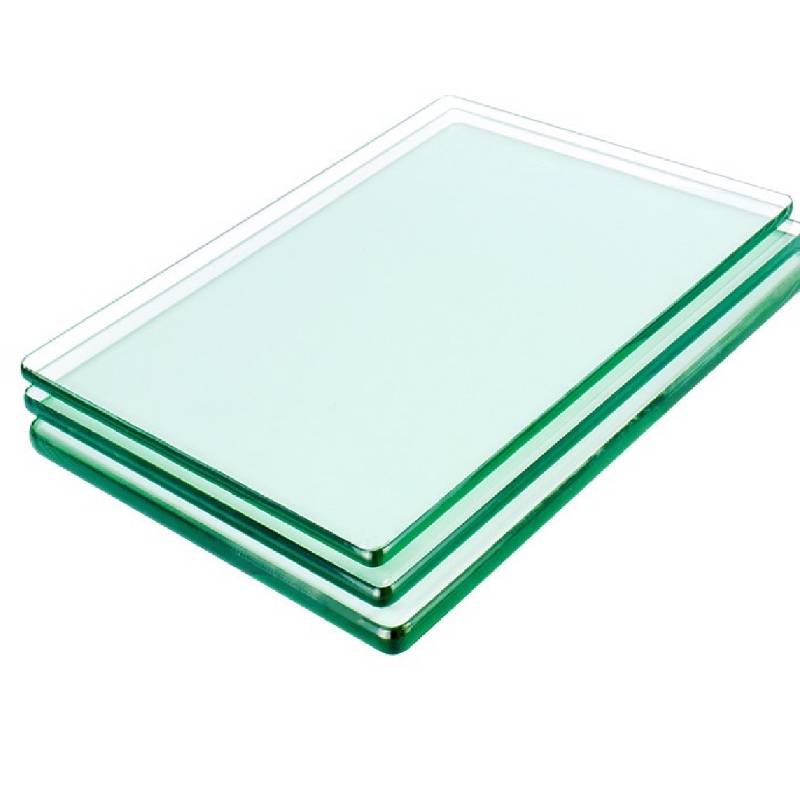

- 1. High transparency

Moru glass uses high-quality glass raw materials with high purity, so the transparency is very good and can provide excellent visual effects.

2. A sense of haziness

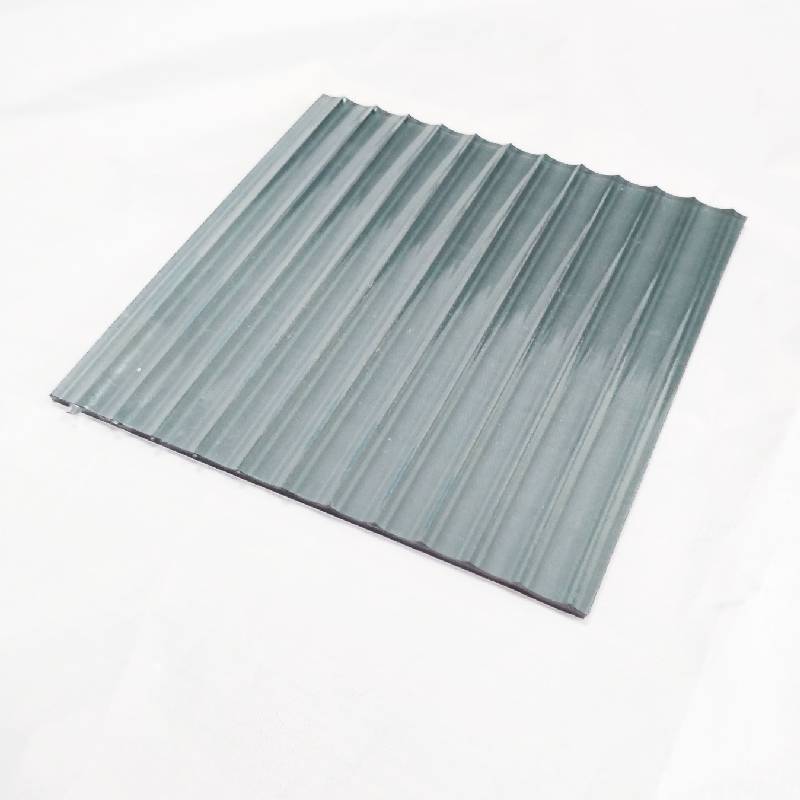

The vertical line texture of Moru glass has a simple geometric beauty and hazy feeling, which can have a semi-covering effect while maintaining spatial transparency.

3. Transparent but not see-through

Moru glass itself is glass, with the characteristics of glass itself transmitting light. In addition, due to its own grooves with a blurred matte surface, the reflected light, plants or decorations on the other side of the glass can be out of focus. More hazy beauty.

4. Good appearance and wide application

As a high-quality, high-transparency glass material, Moru glass has a variety of functions and functions. It has been widely used in construction, home decoration, automobile and other fields.

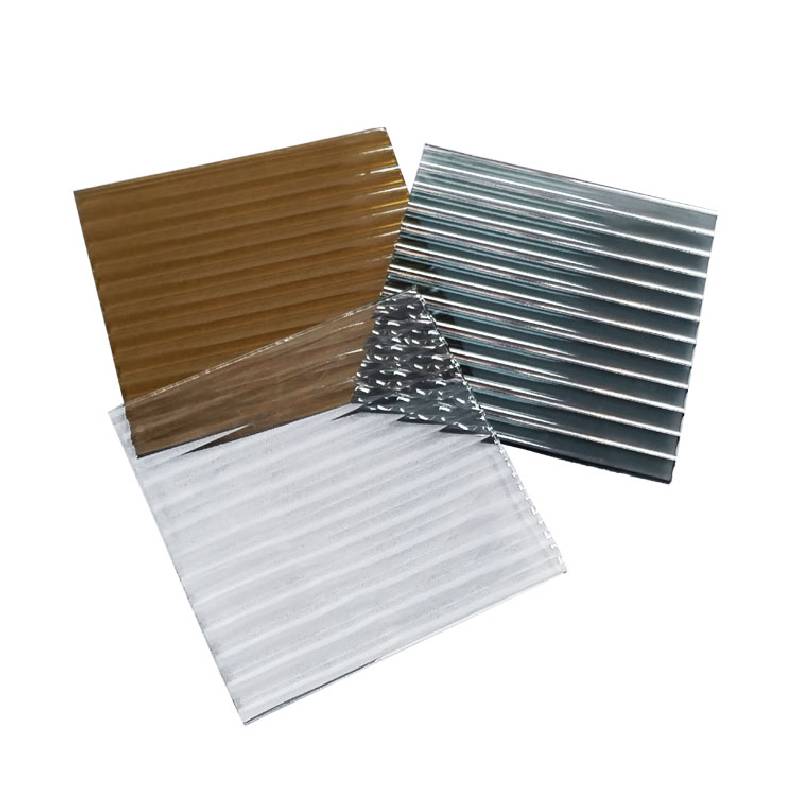

Clear Moru glass, ultra clear Moru glass, gray Moru glass, bronze Moru glass, golden Moru glass.

Regular thickness: 4mm, 5mm, 6mm, 8mm, 10mm

Regular size 2000*2440mm, 2100*2440mm, 2100*2800mm, 2100*3300mm

Afrika

Afrika  Albania

Albania  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Asụsụ Bosnia

Asụsụ Bosnia  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Asụsụ Croatia

Asụsụ Croatia  Czech

Czech  Danish

Danish  Dutch

Dutch  Bekee

Bekee  Esperanto

Esperanto  Estonia

Estonia  Asụsụ Finnish

Asụsụ Finnish  French

French  Onye Frisian

Onye Frisian  Onye Galisi

Onye Galisi  Asụsụ Georgian

Asụsụ Georgian  German

German  Grik

Grik  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  Hawaian

Hawaian  Hibru

Hibru  Mba

Mba  Miao

Miao  Asụsụ Hungarian

Asụsụ Hungarian  Aislandi

Aislandi  igbo

igbo  Asụsụ Indonesian

Asụsụ Indonesian  Irish

Irish  Ịtali

Ịtali  Japanese

Japanese  Asụsụ Javanị

Asụsụ Javanị  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Onye Rwandan

Onye Rwandan  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  TB

TB  Latịn

Latịn  Latvia

Latvia  Lithuania

Lithuania  Luxembourgish

Luxembourgish  Masedonia

Masedonia  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Malta

Malta  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Asụsụ Persia

Asụsụ Persia  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Asụsụ Serbian

Asụsụ Serbian  Bekee

Bekee  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Asụsụ Sudan

Asụsụ Sudan  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  onye Ukraine

onye Ukraine  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Enyemaka

Enyemaka  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu