- 1. Raw material selection: The process starts with the selection of high-quality raw materials, usually silica sand, soda ash and limestone. These materials were chosen for their purity and consistency, as they greatly influence the final quality of the glass.

2. Ingredients: The selected raw materials are accurately weighed and mixed together in specific proportions. This mixture, called a batch, is loaded into a furnace and melted.

3. Melting: The batch is fed into a furnace that is heated to extremely high temperatures, typically between 1,500 and 1,700 degrees Celsius (2,732 and 3,092 degrees Fahrenheit), depending on the type of glass being produced. Intense heat melts the batch into a viscous liquid called molten glass.

4. Shaping: Once the molten glass reaches the desired consistency, it is formed into the desired shape. This can be done by various methods such as blowing, pressing or moulding. For Moru glass, which often has intricate patterns, techniques such as glass blowing or hand shaping can be used to achieve the desired design.

6. Annealing: Newly formed glass undergoes a process called annealing to eliminate internal stress and strengthen the glass. This involves gradually cooling the glass at a controlled rate to ensure an even temperature distribution throughout the material.

7. Finishing: After annealing is complete, inspect the glass for any defects or blemishes. Any rough edges or sharp points are smoothed away, and the final product is cleaned and polished to enhance its appearance.

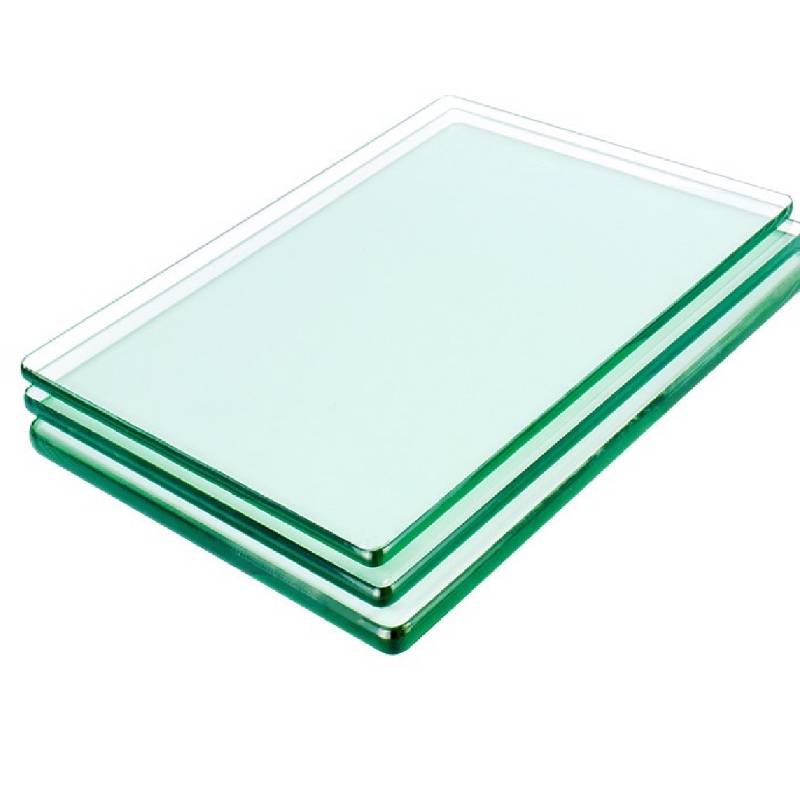

- 1. High transparency

Moru glass uses high-quality glass raw materials with high purity, so the transparency is very good and can provide excellent visual effects.

2. A sense of haziness

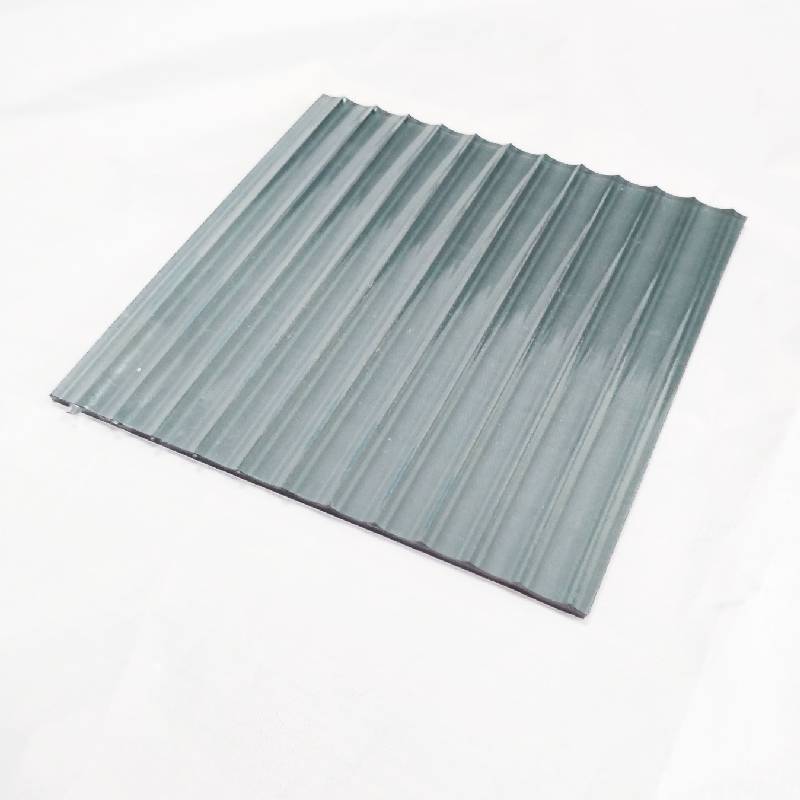

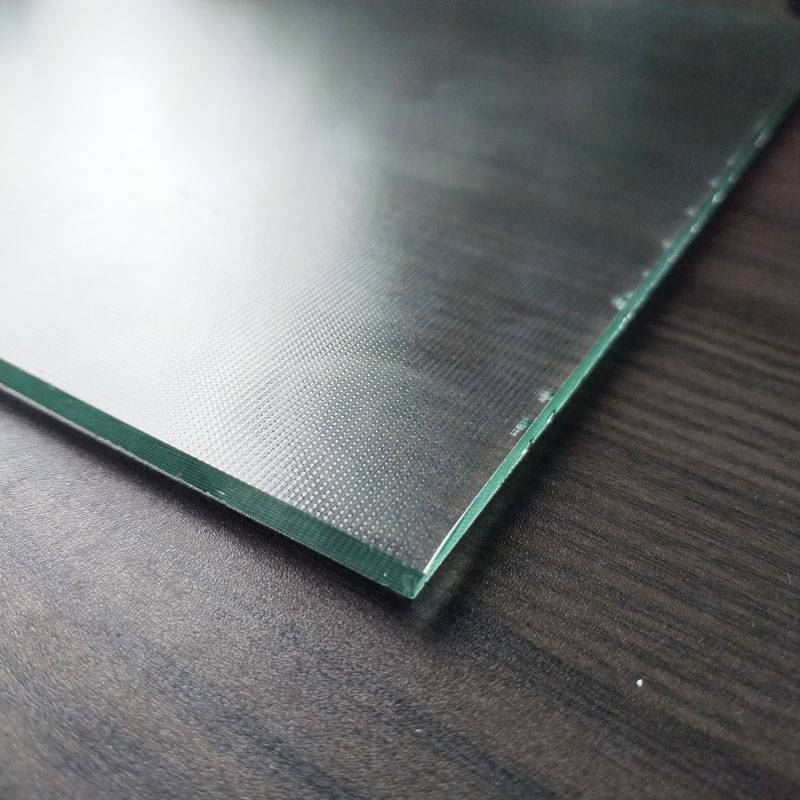

The vertical line texture of Moru glass has a simple geometric beauty and hazy feeling, which can have a semi-covering effect while maintaining spatial transparency.

3. Transparent but not see-through

Moru glass itself is glass, with the characteristics of glass itself transmitting light. In addition, due to its own grooves with a blurred matte surface, the reflected light, plants or decorations on the other side of the glass can be out of focus. More hazy beauty.

4. Good appearance and wide application

As a high-quality, high-transparency glass material, Moru glass has a variety of functions and functions. It has been widely used in construction, home decoration, automobile and other fields.

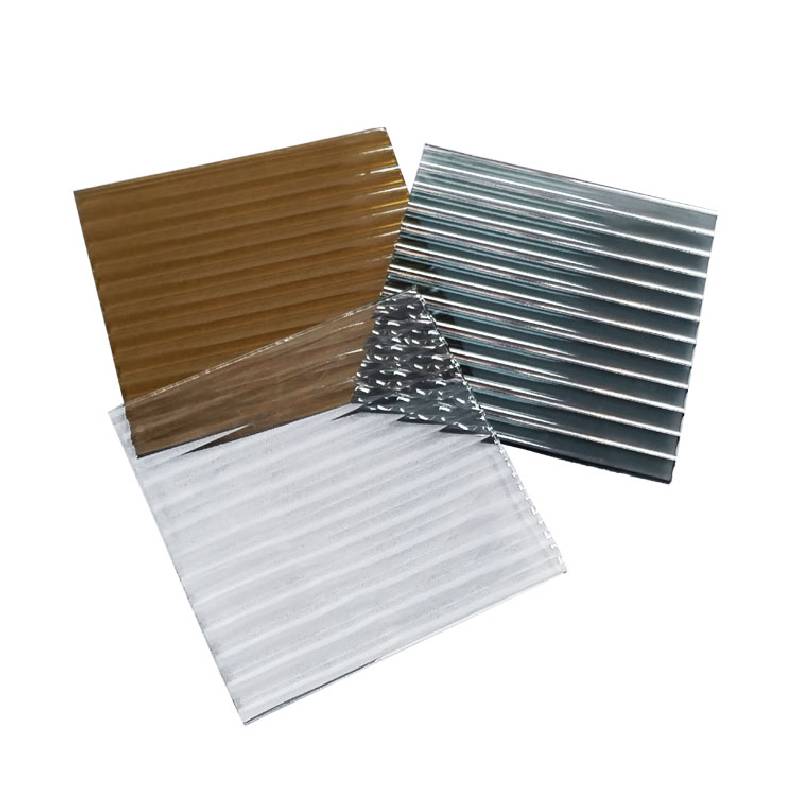

Clear Moru glass, ultra clear Moru glass, gray Moru glass, bronze Moru glass, golden Moru glass.

Regular thickness: 4mm, 5mm, 6mm, 8mm, 10mm

Regular size 2000*2440mm, 2100*2440mm, 2100*2800mm, 2100*3300mm

아프리카 사람

아프리카 사람  알바니아

알바니아  암하라어

암하라어  아라비아 말

아라비아 말  아르메니아 사람

아르메니아 사람  아제르바이잔

아제르바이잔  바스크 사람

바스크 사람  벨로루시어

벨로루시어  벵골 사람

벵골 사람  보스니아어

보스니아어  불가리아 사람

불가리아 사람  카탈로니아 사람

카탈로니아 사람  세부아노어

세부아노어  코르시카어

코르시카어  크로아티아어

크로아티아어  체코 사람

체코 사람  덴마크 말

덴마크 말  네덜란드 사람

네덜란드 사람  영어

영어  에스페란토 말

에스페란토 말  에스토니아 사람

에스토니아 사람  핀란드어

핀란드어  프랑스 국민

프랑스 국민  프리지아어

프리지아어  갈리시아어

갈리시아어  그루지야 사람

그루지야 사람  독일 사람

독일 사람  그리스 어

그리스 어  구자라트어

구자라트어  아이티 크리올어

아이티 크리올어  하우사

하우사  하와이 사람

하와이 사람  헤브라이 사람

헤브라이 사람  아니요

아니요  먀오족

먀오족  헝가리 인

헝가리 인  아이슬란드어

아이슬란드어  이보

이보  인도네시아 인

인도네시아 인  아일랜드의

아일랜드의  이탈리아 사람

이탈리아 사람  일본어

일본어  자바어

자바어  칸나다어

칸나다어  카자흐어

카자흐어  크메르어

크메르어  르완다

르완다  한국인

한국인  쿠르드어

쿠르드어  키르기스어

키르기스어  결핵

결핵  라틴어

라틴어  라트비아 사람

라트비아 사람  리투아니아 사람

리투아니아 사람  룩셈부르크어

룩셈부르크어  마케도니아 어

마케도니아 어  말가시

말가시  말레이 사람

말레이 사람  말라얄람어

말라얄람어  몰티즈

몰티즈  마오리족

마오리족  마라티어

마라티어  몽고 어

몽고 어  미얀마

미얀마  네팔어

네팔어  노르웨이 인

노르웨이 인  노르웨이 인

노르웨이 인  옥시탄

옥시탄  파슈토어

파슈토어  페르시아 인

페르시아 인  광택

광택  포르투갈 인

포르투갈 인  펀자브어

펀자브어  루마니아 사람

루마니아 사람  러시아인

러시아인  사모아어

사모아어  스코틀랜드 게일어

스코틀랜드 게일어  세르비아 사람

세르비아 사람  영어

영어  쇼나

쇼나  신디어

신디어  신할라어

신할라어  슬로바키아 사람

슬로바키아 사람  슬로베니아

슬로베니아  소말리아어

소말리아어  스페인의

스페인의  순다어

순다어  스와힐리어

스와힐리어  스웨덴어

스웨덴어  타갈로그어

타갈로그어  타지크어

타지크어  타밀 사람

타밀 사람  타타르어

타타르어  텔루구어

텔루구어  태국어

태국어  터키어

터키어  투르크멘 말

투르크멘 말  우크라이나 인

우크라이나 인  우르두어

우르두어  위구르어

위구르어  우즈벡어

우즈벡어  베트남어

베트남어  웨일스 말

웨일스 말  돕다

돕다  이디시어

이디시어  요루바어

요루바어  줄루 족

줄루 족