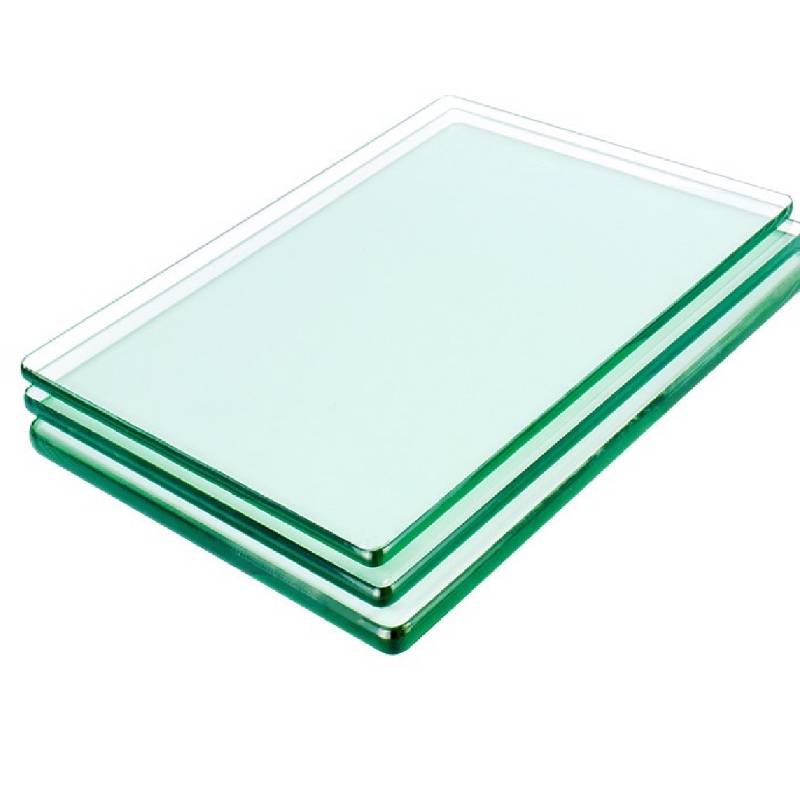

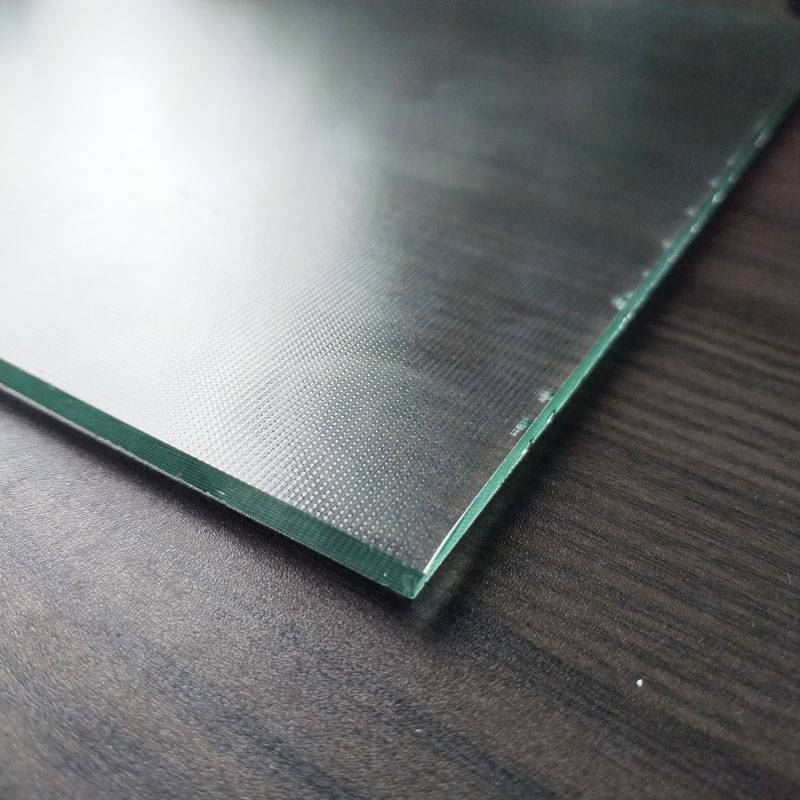

Float glass means that the raw materials are melted at high temperature in the furnace. The molten glass continuously flows from the furnace and floats on the surface of the relatively dense tin liquid. Under the action of gravity and surface tension, the glass liquid spreads on the tin liquid surface. It is opened, flattened, and the upper and lower surfaces are formed to be smooth, hardened, and cooled before being led to the transition roller table. The rollers on the roller table rotate, pulling the glass ribbon out of the tin bath and into the annealing kiln. After annealing and cutting, flat glass products are obtained. The biggest feature of float glass is that its surface is hard, smooth, and flat. Especially when viewed from the side, the color is different from ordinary glass. It is white and the object is not distorted after reflection. In addition, due to the relatively good thickness uniformity, the transparency of its products is also relatively strong. It is precisely because of this transparency that it has a wider field of view. The broad field of view allows float glass to be used in many fields.

The production process of float glass is completed in a tin bath where protective gas (N2 and H2) is introduced. Molten glass continuously flows from the tank kiln and floats on the surface of the relatively dense tin liquid. Under the action of gravity and surface tension, the molten glass spreads and flattens on the tin liquid surface, forming an upper and lower surface that is smooth, hardened, and cooled. Then he was led to the transition roller table. The rollers on the roller table rotate, pulling the glass ribbon out of the tin bath and into the annealing kiln. After annealing and cutting, flat glass products are obtained. Compared with other forming methods, the advantages of float method are: it is suitable for high-efficiency manufacturing of high-quality flat glass, such as no corrugation, uniform thickness, smooth upper and lower surfaces, and parallel to each other; the scale of the production line is not limited by the forming method, and the energy per unit product Low consumption; high utilization rate of finished products; easy to scientifically manage and realize full-line mechanization and automation, high labor productivity; continuous operation cycle can last for several years, which is conducive to stable production; can provide suitable conditions for online production of some new varieties, such as Electric float reflective glass, spray film glass during annealing, cold end surface treatment, etc.

Float glass is widely used and is divided into tinted glass, float silver mirror, float white glass, etc. Among them, ultra-white float glass has a wide range of uses and broad market prospects. It is mainly used in the fields of high-end buildings, high-end glass processing and solar photovoltaic curtain walls, as well as high-end glass furniture, decorative glass, imitation crystal products, lighting glass, precision electronics industries, Special buildings, etc. Float glass has relatively good thickness uniformity and relatively strong transparency. Therefore, after tin surface treatment, it is relatively smooth. Under the action of smoothing, flame and polishing, it forms a surface that is relatively neat and flat. Glass with better strength and stronger optical properties. This kind of float glass has the characteristics of good transparency, brightness, purity, and bright indoor light. It is also the best choice for building doors, windows, and natural lighting materials. It is also one of the most widely used building materials. one.

The history of float glass can be traced back to the late 1950s. The British Pilkington Glass Company announced to the world that it had successfully developed the float forming process for flat glass. This was a revolution in the original grooved top forming process. However, the Western technology blockade at that time made China's float glass development and production have to take the path of self-reliance and independent innovation. In May 1971, the former Ministry of Building Materials Industry decided to conduct float process industrial trials in Luobo. Glass experts from all over the country gathered in Luobo, and more than a thousand employees of Luobo participated in the war. On September 23, 1971, under the guidance of department leaders and relevant experts, and with the full cooperation of fraternal units, the cadres and workers of Luoyang University worked together for more than three months and finally successfully built the first float. The glass production line produced my country's first float glass. From 1971 to 1981, CLFG implemented large-scale technical transformation on this line three times. The melting capacity of the production line reached 225 tons, the plate width exceeded 2 meters, and the overall yield reached 76.96%. At the end of 1978, In early 1979, thinner 4 mm glass was stably produced. The technology and equipment of "Luoyang Float Glass Process" were also improved day by day, and the technical level was continuously improved.

플로트 유리의 장점은 주로 다음과 같은 측면에 반영됩니다. 첫째, 평탄도가 좋고 물 잔물결이 없습니다. 둘째, 선택한 광석 석영사는 좋은 원료를 가지고 있습니다. 셋째, 생산된 유리는 순수하고 투명성이 좋다. 마지막으로 구조는 작고 무겁고 촉감이 매끄러우며 같은 두께의 평방미터당 평판보다 무겁고 절단이 쉽고 부서지기 쉽지 않습니다. 이러한 장점으로 인해 플로트 유리는 건설, 자동차, 장식, 가구, 정보 산업 기술 및 기타 산업에서 널리 사용됩니다.

- 플로트 유리의 두께

일반 두께 3mm, 4mm, 5.5mm, 6mm, 8mm, 10mm, 12mm

초박형 1.2mm, 1.3mm, 1.5mm, 1.8mm, 2mm, 2.3mm, 2.5mm

특두께 15mm, 19mm

크기 1220*1830mm, 915*2440mm, 915*1220mm, 1524*3300mm, 2140*3300mm, 2140*3660mm, 2250*3300mm, 2440*3660mm

아프리카 사람

아프리카 사람  알바니아

알바니아  암하라어

암하라어  아라비아 말

아라비아 말  아르메니아 사람

아르메니아 사람  아제르바이잔

아제르바이잔  바스크 사람

바스크 사람  벨로루시어

벨로루시어  벵골 사람

벵골 사람  보스니아어

보스니아어  불가리아 사람

불가리아 사람  카탈로니아 사람

카탈로니아 사람  세부아노어

세부아노어  코르시카어

코르시카어  크로아티아어

크로아티아어  체코 사람

체코 사람  덴마크 말

덴마크 말  네덜란드 사람

네덜란드 사람  영어

영어  에스페란토 말

에스페란토 말  에스토니아 사람

에스토니아 사람  핀란드어

핀란드어  프랑스 국민

프랑스 국민  프리지아어

프리지아어  갈리시아어

갈리시아어  그루지야 사람

그루지야 사람  독일 사람

독일 사람  그리스 어

그리스 어  구자라트어

구자라트어  아이티 크리올어

아이티 크리올어  하우사

하우사  하와이 사람

하와이 사람  헤브라이 사람

헤브라이 사람  아니요

아니요  먀오족

먀오족  헝가리 인

헝가리 인  아이슬란드어

아이슬란드어  이보

이보  인도네시아 인

인도네시아 인  아일랜드의

아일랜드의  이탈리아 사람

이탈리아 사람  일본어

일본어  자바어

자바어  칸나다어

칸나다어  카자흐어

카자흐어  크메르어

크메르어  르완다

르완다  한국인

한국인  쿠르드어

쿠르드어  키르기스어

키르기스어  결핵

결핵  라틴어

라틴어  라트비아 사람

라트비아 사람  리투아니아 사람

리투아니아 사람  룩셈부르크어

룩셈부르크어  마케도니아 어

마케도니아 어  말가시

말가시  말레이 사람

말레이 사람  말라얄람어

말라얄람어  몰티즈

몰티즈  마오리족

마오리족  마라티어

마라티어  몽고 어

몽고 어  미얀마

미얀마  네팔어

네팔어  노르웨이 인

노르웨이 인  노르웨이 인

노르웨이 인  옥시탄

옥시탄  파슈토어

파슈토어  페르시아 인

페르시아 인  광택

광택  포르투갈 인

포르투갈 인  펀자브어

펀자브어  루마니아 사람

루마니아 사람  러시아인

러시아인  사모아어

사모아어  스코틀랜드 게일어

스코틀랜드 게일어  세르비아 사람

세르비아 사람  영어

영어  쇼나

쇼나  신디어

신디어  신할라어

신할라어  슬로바키아 사람

슬로바키아 사람  슬로베니아

슬로베니아  소말리아어

소말리아어  스페인의

스페인의  순다어

순다어  스와힐리어

스와힐리어  스웨덴어

스웨덴어  타갈로그어

타갈로그어  타지크어

타지크어  타밀 사람

타밀 사람  타타르어

타타르어  텔루구어

텔루구어  태국어

태국어  터키어

터키어  투르크멘 말

투르크멘 말  우크라이나 인

우크라이나 인  우르두어

우르두어  위구르어

위구르어  우즈벡어

우즈벡어  베트남어

베트남어  웨일스 말

웨일스 말  돕다

돕다  이디시어

이디시어  요루바어

요루바어  줄루 족

줄루 족