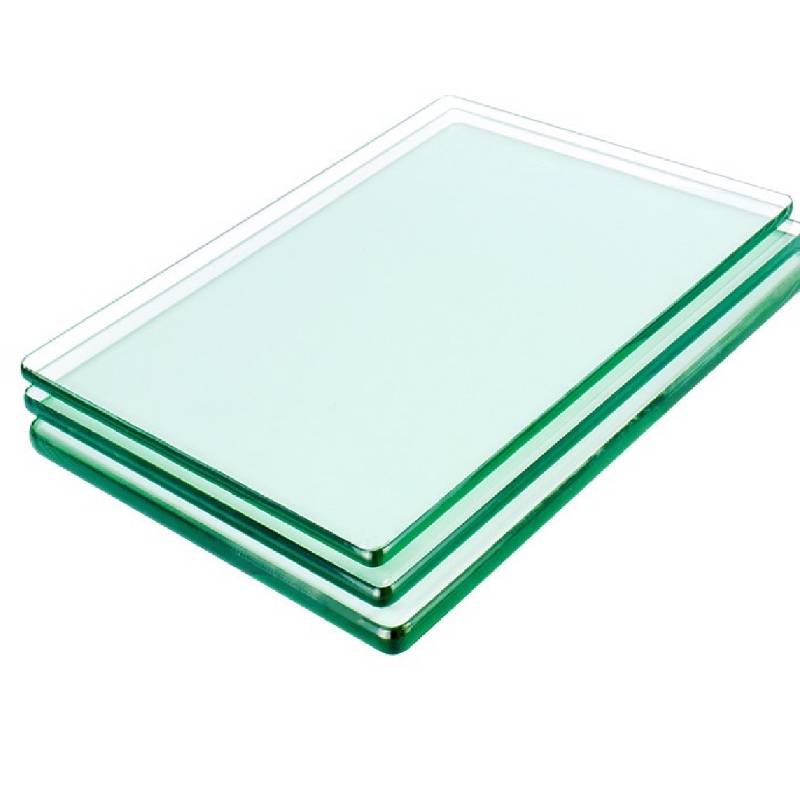

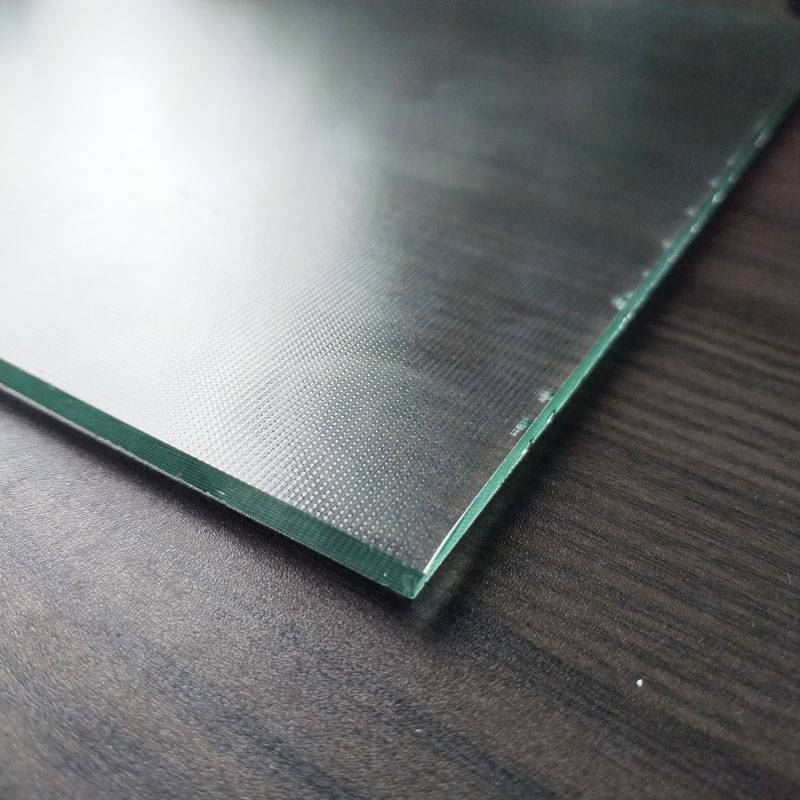

Float glass means that the raw materials are melted at high temperature in the furnace. The molten glass continuously flows from the furnace and floats on the surface of the relatively dense tin liquid. Under the action of gravity and surface tension, the glass liquid spreads on the tin liquid surface. It is opened, flattened, and the upper and lower surfaces are formed to be smooth, hardened, and cooled before being led to the transition roller table. The rollers on the roller table rotate, pulling the glass ribbon out of the tin bath and into the annealing kiln. After annealing and cutting, flat glass products are obtained. The biggest feature of float glass is that its surface is hard, smooth, and flat. Especially when viewed from the side, the color is different from ordinary glass. It is white and the object is not distorted after reflection. In addition, due to the relatively good thickness uniformity, the transparency of its products is also relatively strong. It is precisely because of this transparency that it has a wider field of view. The broad field of view allows float glass to be used in many fields.

The production process of float glass is completed in a tin bath where protective gas (N2 and H2) is introduced. Molten glass continuously flows from the tank kiln and floats on the surface of the relatively dense tin liquid. Under the action of gravity and surface tension, the molten glass spreads and flattens on the tin liquid surface, forming an upper and lower surface that is smooth, hardened, and cooled. Then he was led to the transition roller table. The rollers on the roller table rotate, pulling the glass ribbon out of the tin bath and into the annealing kiln. After annealing and cutting, flat glass products are obtained. Compared with other forming methods, the advantages of float method are: it is suitable for high-efficiency manufacturing of high-quality flat glass, such as no corrugation, uniform thickness, smooth upper and lower surfaces, and parallel to each other; the scale of the production line is not limited by the forming method, and the energy per unit product Low consumption; high utilization rate of finished products; easy to scientifically manage and realize full-line mechanization and automation, high labor productivity; continuous operation cycle can last for several years, which is conducive to stable production; can provide suitable conditions for online production of some new varieties, such as Electric float reflective glass, spray film glass during annealing, cold end surface treatment, etc.

Float glass is widely used and is divided into tinted glass, float silver mirror, float white glass, etc. Among them, ultra-white float glass has a wide range of uses and broad market prospects. It is mainly used in the fields of high-end buildings, high-end glass processing and solar photovoltaic curtain walls, as well as high-end glass furniture, decorative glass, imitation crystal products, lighting glass, precision electronics industries, Special buildings, etc. Float glass has relatively good thickness uniformity and relatively strong transparency. Therefore, after tin surface treatment, it is relatively smooth. Under the action of smoothing, flame and polishing, it forms a surface that is relatively neat and flat. Glass with better strength and stronger optical properties. This kind of float glass has the characteristics of good transparency, brightness, purity, and bright indoor light. It is also the best choice for building doors, windows, and natural lighting materials. It is also one of the most widely used building materials. one.

The history of float glass can be traced back to the late 1950s. The British Pilkington Glass Company announced to the world that it had successfully developed the float forming process for flat glass. This was a revolution in the original grooved top forming process. However, the Western technology blockade at that time made China's float glass development and production have to take the path of self-reliance and independent innovation. In May 1971, the former Ministry of Building Materials Industry decided to conduct float process industrial trials in Luobo. Glass experts from all over the country gathered in Luobo, and more than a thousand employees of Luobo participated in the war. On September 23, 1971, under the guidance of department leaders and relevant experts, and with the full cooperation of fraternal units, the cadres and workers of Luoyang University worked together for more than three months and finally successfully built the first float. The glass production line produced my country's first float glass. From 1971 to 1981, CLFG implemented large-scale technical transformation on this line three times. The melting capacity of the production line reached 225 tons, the plate width exceeded 2 meters, and the overall yield reached 76.96%. At the end of 1978, In early 1979, thinner 4 mm glass was stably produced. The technology and equipment of "Luoyang Float Glass Process" were also improved day by day, and the technical level was continuously improved.

Fördelarna med floatglas återspeglas främst i följande aspekter: för det första har det bra planhet och inga vattenvågor; för det andra har den valda malmkvartssanden bra råvaror; för det tredje är glaset som produceras rent och har god transparens; slutligen strukturen Kompakt, tung, smidig vid beröring, tyngre än en platt platta per kvadratmeter av samma tjocklek, lätt att skära och inte lätt att bryta. Dessa fördelar gör att floatglas används i stor utsträckning inom konstruktion, bilar, dekoration, möbler, informationsindustriteknik och andra industrier.

- Tjocklek på floatglas

Vanlig tjocklek 3 mm, 4 mm, 5,5 mm, 6 mm, 8 mm, 10 mm, 12 mm

Ultratunn 1,2 mm, 1,3 mm, 1,5 mm, 1,8 mm, 2 mm, 2,3 mm, 2,5 mm

Extra tjock 15mm, 19mm

Storlek 1220*1830mm, 915*2440mm, 915*1220mm, 1524*3300mm, 2140*3300mm, 2140*3660mm, 2250*3300mm, 2440*3660mm

afrikanska

afrikanska  albanska

albanska  amhariska

amhariska  arabiska

arabiska  armeniska

armeniska  azerbajdzjanska

azerbajdzjanska  baskiska

baskiska  vitryska

vitryska  bengaliska

bengaliska  bosniska

bosniska  bulgariska

bulgariska  katalanska

katalanska  Cebuano

Cebuano  korsikanska

korsikanska  Kroatisk

Kroatisk  tjeckiska

tjeckiska  danska

danska  holländska

holländska  engelsk

engelsk  esperanto

esperanto  estniska

estniska  finska

finska  franska

franska  frisiska

frisiska  galiciska

galiciska  georgiska

georgiska  tysk

tysk  grekisk

grekisk  Gujarati

Gujarati  haitisk kreol

haitisk kreol  hausa

hausa  hawaiian

hawaiian  hebreiska

hebreiska  Nej

Nej  Miao

Miao  ungerska

ungerska  isländska

isländska  igbo

igbo  indonesiska

indonesiska  irländsk

irländsk  italienska

italienska  japanska

japanska  javanesiska

javanesiska  Kannada

Kannada  kazakiska

kazakiska  Khmer

Khmer  rwandiska

rwandiska  koreanska

koreanska  kurdiska

kurdiska  kirgiziska

kirgiziska  TB

TB  latin

latin  lettiska

lettiska  litauiska

litauiska  Luxemburgiska

Luxemburgiska  makedonska

makedonska  Malgashi

Malgashi  malajiska

malajiska  Malayalam

Malayalam  maltesiska

maltesiska  Maori

Maori  Marathi

Marathi  mongoliska

mongoliska  Myanmar

Myanmar  nepalesiska

nepalesiska  norska

norska  norska

norska  occitanska

occitanska  Pashto

Pashto  persiska

persiska  putsa

putsa  portugisiska

portugisiska  Punjabi

Punjabi  rumänska

rumänska  ryska

ryska  Samoan

Samoan  skotsk gaeliska

skotsk gaeliska  serbiska

serbiska  engelsk

engelsk  Shona

Shona  Sindhi

Sindhi  singalesiska

singalesiska  slovakiska

slovakiska  slovenska

slovenska  somaliska

somaliska  spanska

spanska  Sundanesiska

Sundanesiska  Swahili

Swahili  svenska

svenska  Tagalog

Tagalog  tadzjikiska

tadzjikiska  Tamil

Tamil  tatariska

tatariska  Telugu

Telugu  Thai

Thai  turkiska

turkiska  turkmeniska

turkmeniska  ukrainska

ukrainska  Urdu

Urdu  Uigur

Uigur  uzbekiska

uzbekiska  vietnamesiska

vietnamesiska  walesiska

walesiska  Hjälp

Hjälp  jiddisch

jiddisch  Yoruba

Yoruba  Zulu

Zulu