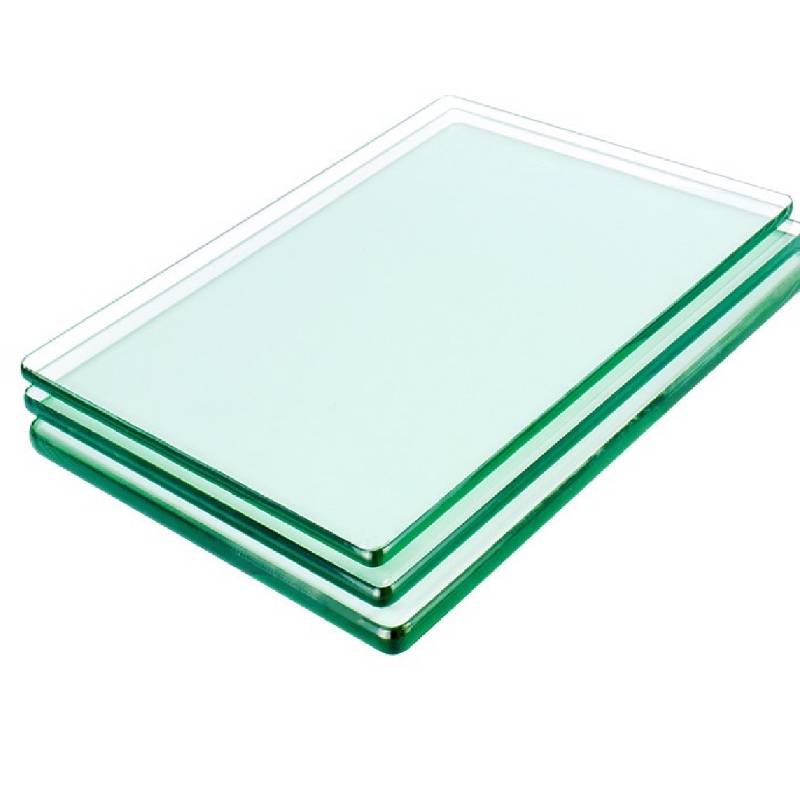

Aluminum mirror, also known as aluminized glass mirror, glass mirror, mirror glass, mirror plate glass, is a commonly used mirror type. The reflective layer on the back is aluminum-coated. Compared with silver-coated glass mirrors, aluminum mirrors have lower reflectivity.

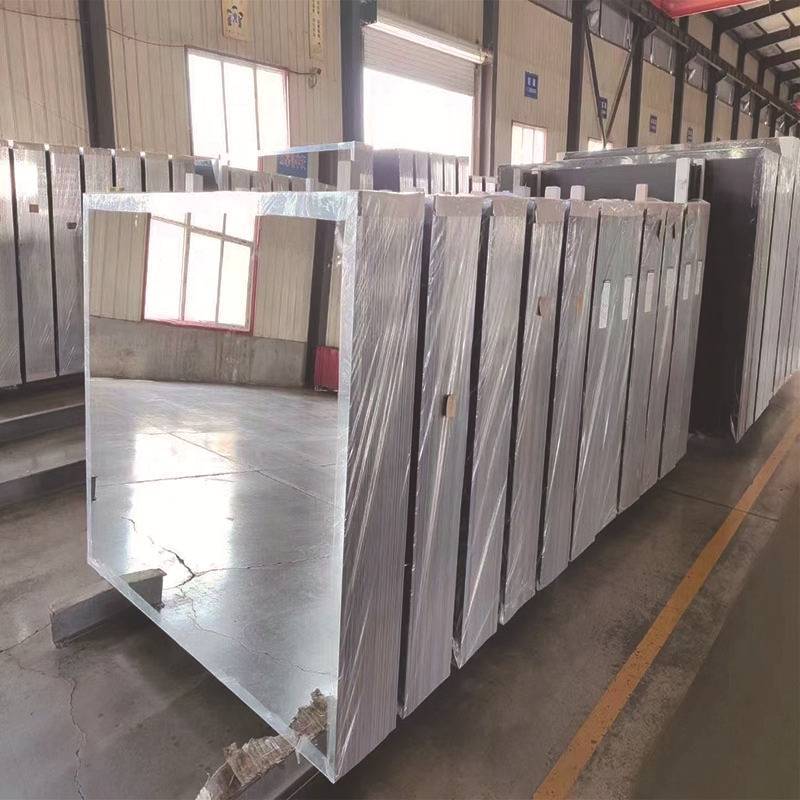

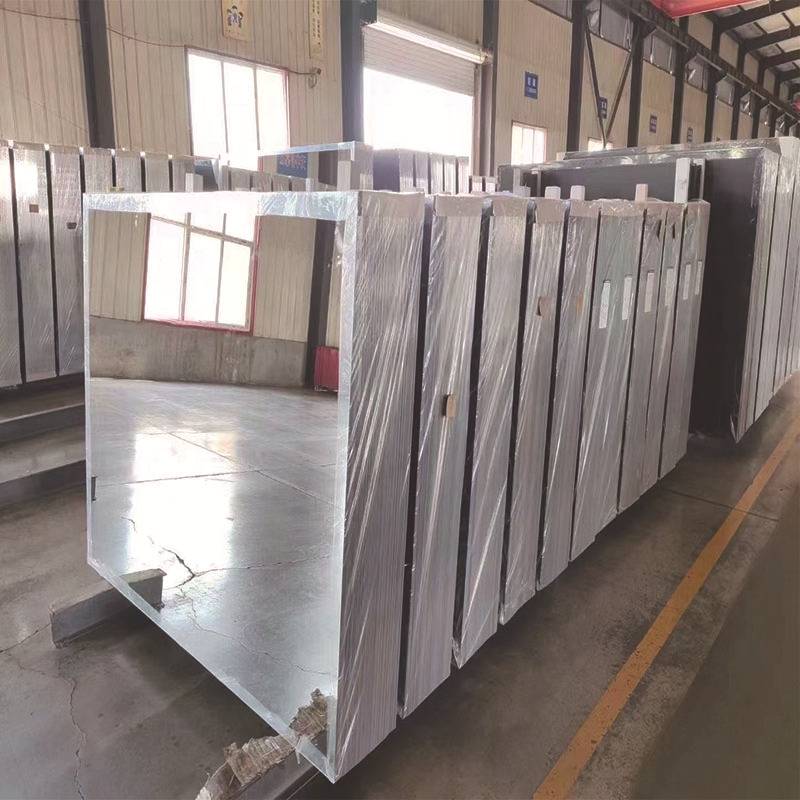

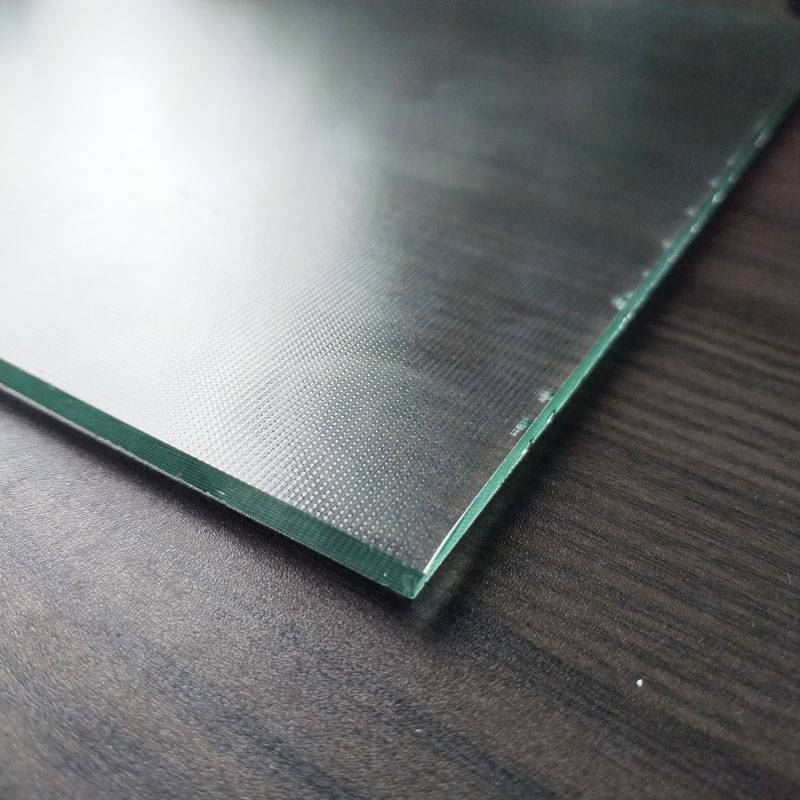

The production process of aluminum mirrors includes but is not limited to the following steps: first, use high-quality float glass plates as the original piece; then, go through a series of cleaning and polishing steps; then, perform metal magnetron sputtering deposition and plating under high vacuum conditions Aluminum; finally, it is made through rapid oxygen reaction and multiple paint spraying and drying processes.

The difference between aluminum mirror and silver mirror

Aluminum mirrors and silver mirrors are very similar in appearance, but there are significant differences in their production materials, cost, performance, etc. The production process of silver mirrors is more complicated, so there will be differences in quality and price.

Aluminum mirrors are made of metallic aluminum, while silver mirrors are made of silver electroplating. The price of silver mirrors is much higher than that of aluminum mirrors, but aluminum mirrors have low cost and long service life. In terms of brightness, the refractive property of silver mirrors is higher than that of aluminum mirrors, so under equal light intensity, silver mirrors look brighter.

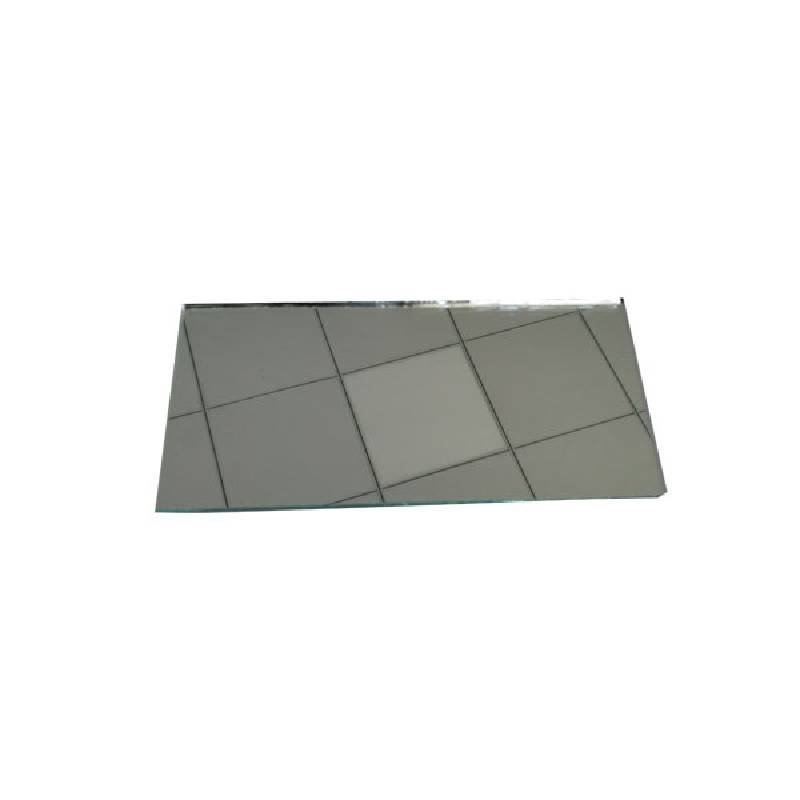

Aluminum mirrors are widely used and can be used in various occasions such as cosmetic mirrors and furniture. High-grade float aluminum mirrors can also be made into colored mirrors of various colors to add different decorative effects, such as gray mirrors, brown mirrors, green mirrors, blue mirrors, etc. Aluminum mirrors can range in thickness from 1.1mm to 8mm, with a maximum size of 2440x3660mm (96X144 inches). In addition, aluminum mirrors can also be used in sanitary ware and other places.

Aluminum mirrors are divided into single-coated aluminum mirrors and double-coated aluminum mirrors

The thickness of the aluminum mirror is 1.1mm, 1.2mm, 1.3mm, 1.8mm, 2mm, 2.3mm, 2.5mm, 2.8mm, 3mm, 3.2mm, 3.5mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm

The conventional sizes of aluminum mirrors are 1220*1830mm, 1830*915mm, 610*915mm, 1830*2440mm, 2140*3300mm, 2140*3660mm, 2250*3300mm, 2250*3660mm, 2440*3660mm

When choosing aluminum mirrors, you can decide based on specific application scenarios and needs. For example, STD-M standard aluminum mirrors can be used where high reflectivity is required. In terms of maintenance, you should avoid touching the surface of the aluminum mirror with your hands or objects to prevent contamination and damage.

When cleaning the surface of an aluminum mirror, you should first use high-pressure gas to blow off the dirt and dust on the surface, and then use traction cleaning to remove fingerprints and fixed residues on the surface.

One of the great features of aluminum mirrors is their relatively low price. This is because the raw material cost of aluminum is much cheaper than silver, so the price of aluminum mirrors is correspondingly lower. This is a big advantage for consumers looking for affordable prices.

Another feature of aluminum mirrors is their ease of mass production. Since the production process of aluminum mirrors is relatively simple and can improve production efficiency to a certain extent, it is more suitable for mass production. This also makes aluminum mirrors more popular and common in the market.

afrikanska

afrikanska  albanska

albanska  amhariska

amhariska  arabiska

arabiska  armeniska

armeniska  azerbajdzjanska

azerbajdzjanska  baskiska

baskiska  vitryska

vitryska  bengaliska

bengaliska  bosniska

bosniska  bulgariska

bulgariska  katalanska

katalanska  Cebuano

Cebuano  korsikanska

korsikanska  Kroatisk

Kroatisk  tjeckiska

tjeckiska  danska

danska  holländska

holländska  engelsk

engelsk  esperanto

esperanto  estniska

estniska  finska

finska  franska

franska  frisiska

frisiska  galiciska

galiciska  georgiska

georgiska  tysk

tysk  grekisk

grekisk  Gujarati

Gujarati  haitisk kreol

haitisk kreol  hausa

hausa  hawaiian

hawaiian  hebreiska

hebreiska  Nej

Nej  Miao

Miao  ungerska

ungerska  isländska

isländska  igbo

igbo  indonesiska

indonesiska  irländsk

irländsk  italienska

italienska  japanska

japanska  javanesiska

javanesiska  Kannada

Kannada  kazakiska

kazakiska  Khmer

Khmer  rwandiska

rwandiska  koreanska

koreanska  kurdiska

kurdiska  kirgiziska

kirgiziska  TB

TB  latin

latin  lettiska

lettiska  litauiska

litauiska  Luxemburgiska

Luxemburgiska  makedonska

makedonska  Malgashi

Malgashi  malajiska

malajiska  Malayalam

Malayalam  maltesiska

maltesiska  Maori

Maori  Marathi

Marathi  mongoliska

mongoliska  Myanmar

Myanmar  nepalesiska

nepalesiska  norska

norska  norska

norska  occitanska

occitanska  Pashto

Pashto  persiska

persiska  putsa

putsa  portugisiska

portugisiska  Punjabi

Punjabi  rumänska

rumänska  ryska

ryska  Samoan

Samoan  skotsk gaeliska

skotsk gaeliska  serbiska

serbiska  engelsk

engelsk  Shona

Shona  Sindhi

Sindhi  singalesiska

singalesiska  slovakiska

slovakiska  slovenska

slovenska  somaliska

somaliska  spanska

spanska  Sundanesiska

Sundanesiska  Swahili

Swahili  svenska

svenska  Tagalog

Tagalog  tadzjikiska

tadzjikiska  Tamil

Tamil  tatariska

tatariska  Telugu

Telugu  Thai

Thai  turkiska

turkiska  turkmeniska

turkmeniska  ukrainska

ukrainska  Urdu

Urdu  Uigur

Uigur  uzbekiska

uzbekiska  vietnamesiska

vietnamesiska  walesiska

walesiska  Hjälp

Hjälp  jiddisch

jiddisch  Yoruba

Yoruba  Zulu

Zulu