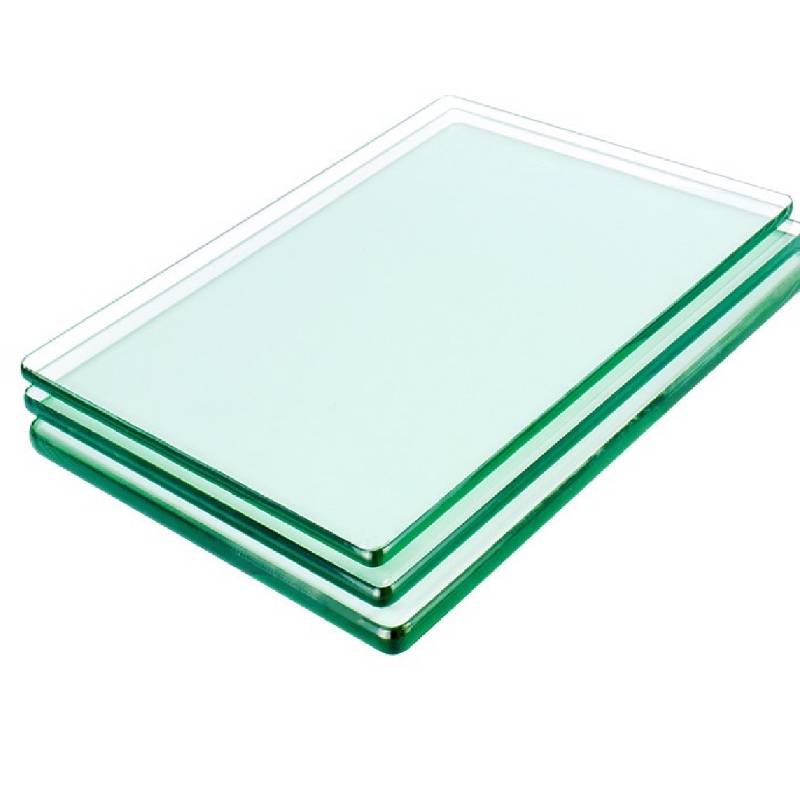

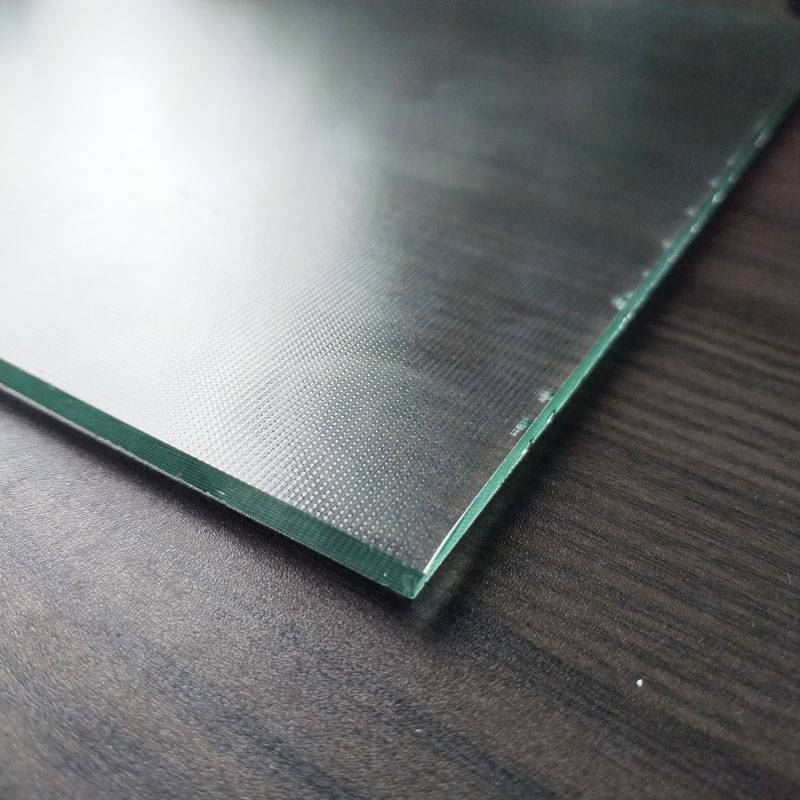

Float glass means that the raw materials are melted at high temperature in the furnace. The molten glass continuously flows from the furnace and floats on the surface of the relatively dense tin liquid. Under the action of gravity and surface tension, the glass liquid spreads on the tin liquid surface. It is opened, flattened, and the upper and lower surfaces are formed to be smooth, hardened, and cooled before being led to the transition roller table. The rollers on the roller table rotate, pulling the glass ribbon out of the tin bath and into the annealing kiln. After annealing and cutting, flat glass products are obtained. The biggest feature of float glass is that its surface is hard, smooth, and flat. Especially when viewed from the side, the color is different from ordinary glass. It is white and the object is not distorted after reflection. In addition, due to the relatively good thickness uniformity, the transparency of its products is also relatively strong. It is precisely because of this transparency that it has a wider field of view. The broad field of view allows float glass to be used in many fields.

The production process of float glass is completed in a tin bath where protective gas (N2 and H2) is introduced. Molten glass continuously flows from the tank kiln and floats on the surface of the relatively dense tin liquid. Under the action of gravity and surface tension, the molten glass spreads and flattens on the tin liquid surface, forming an upper and lower surface that is smooth, hardened, and cooled. Then he was led to the transition roller table. The rollers on the roller table rotate, pulling the glass ribbon out of the tin bath and into the annealing kiln. After annealing and cutting, flat glass products are obtained. Compared with other forming methods, the advantages of float method are: it is suitable for high-efficiency manufacturing of high-quality flat glass, such as no corrugation, uniform thickness, smooth upper and lower surfaces, and parallel to each other; the scale of the production line is not limited by the forming method, and the energy per unit product Low consumption; high utilization rate of finished products; easy to scientifically manage and realize full-line mechanization and automation, high labor productivity; continuous operation cycle can last for several years, which is conducive to stable production; can provide suitable conditions for online production of some new varieties, such as Electric float reflective glass, spray film glass during annealing, cold end surface treatment, etc.

Float glass is widely used and is divided into tinted glass, float silver mirror, float white glass, etc. Among them, ultra-white float glass has a wide range of uses and broad market prospects. It is mainly used in the fields of high-end buildings, high-end glass processing and solar photovoltaic curtain walls, as well as high-end glass furniture, decorative glass, imitation crystal products, lighting glass, precision electronics industries, Special buildings, etc. Float glass has relatively good thickness uniformity and relatively strong transparency. Therefore, after tin surface treatment, it is relatively smooth. Under the action of smoothing, flame and polishing, it forms a surface that is relatively neat and flat. Glass with better strength and stronger optical properties. This kind of float glass has the characteristics of good transparency, brightness, purity, and bright indoor light. It is also the best choice for building doors, windows, and natural lighting materials. It is also one of the most widely used building materials. one.

The history of float glass can be traced back to the late 1950s. The British Pilkington Glass Company announced to the world that it had successfully developed the float forming process for flat glass. This was a revolution in the original grooved top forming process. However, the Western technology blockade at that time made China's float glass development and production have to take the path of self-reliance and independent innovation. In May 1971, the former Ministry of Building Materials Industry decided to conduct float process industrial trials in Luobo. Glass experts from all over the country gathered in Luobo, and more than a thousand employees of Luobo participated in the war. On September 23, 1971, under the guidance of department leaders and relevant experts, and with the full cooperation of fraternal units, the cadres and workers of Luoyang University worked together for more than three months and finally successfully built the first float. The glass production line produced my country's first float glass. From 1971 to 1981, CLFG implemented large-scale technical transformation on this line three times. The melting capacity of the production line reached 225 tons, the plate width exceeded 2 meters, and the overall yield reached 76.96%. At the end of 1978, In early 1979, thinner 4 mm glass was stably produced. The technology and equipment of "Luoyang Float Glass Process" were also improved day by day, and the technical level was continuously improved.

Преимущества флоат-стекла в основном отражаются в следующих аспектах: во-первых, оно имеет хорошую плоскостность и отсутствие водной ряби; во-вторых, выбранный рудный кварцевый песок имеет хорошее сырье; в-третьих, производимое стекло чистое и имеет хорошую прозрачность; наконец, структура Компактная, тяжелая, гладкая на ощупь, тяжелее плоской пластины на квадратный метр той же толщины, легко режется и нелегко ломается. Эти преимущества делают флоат-стекло широко используемым в строительстве, автомобилях, отделке, мебели, информационных технологиях и других отраслях.

- Толщина флоат-стекла

Обычная толщина 3 мм, 4 мм, 5,5 мм, 6 мм, 8 мм, 10 мм, 12 мм.

Ультратонкие 1,2 мм, 1,3 мм, 1,5 мм, 1,8 мм, 2 мм, 2,3 мм, 2,5 мм

Очень толстый 15 мм, 19 мм

Размер 1220*1830 мм, 915*2440 мм, 915*1220 мм, 1524*3300 мм, 2140*3300 мм, 2140*3660 мм, 2250*3300 мм, 2440*3660 мм

Африканский

Африканский  албанский

албанский  амхарский

амхарский  арабский

арабский  Армянский

Армянский  азербайджанский

азербайджанский  Баскский

Баскский  белорусский

белорусский  Бенгальский

Бенгальский  Боснийский

Боснийский  болгарский

болгарский  каталанский

каталанский  кебуано

кебуано  корсиканец

корсиканец  хорватский

хорватский  Чешский

Чешский  датский

датский  Голландский

Голландский  Английский

Английский  эсперанто

эсперанто  эстонский

эстонский  финский

финский  Французский

Французский  фризский

фризский  галисийский

галисийский  грузинский

грузинский  Немецкий

Немецкий  греческий

греческий  Гуджарати

Гуджарати  гаитянский креольский

гаитянский креольский  хауса

хауса  гавайский

гавайский  иврит

иврит  Неа

Неа  Мяо

Мяо  Венгерский

Венгерский  исландский

исландский  игбо

игбо  индонезийский

индонезийский  ирландский

ирландский  итальянский

итальянский  Японский

Японский  яванский

яванский  Каннада

Каннада  казахский

казахский  кхмерский

кхмерский  Руандийский

Руандийский  Корейский

Корейский  курдский

курдский  киргизский

киргизский  туберкулез

туберкулез  латинский

латинский  Латышский

Латышский  Литовский

Литовский  Люксембургский

Люксембургский  македонский

македонский  Малгаши

Малгаши  малайский

малайский  малаялам

малаялам  мальтийский

мальтийский  маори

маори  Маратхи

Маратхи  Монгольский

Монгольский  Мьянма

Мьянма  непальский

непальский  Норвежский

Норвежский  Норвежский

Норвежский  окситанский

окситанский  пушту

пушту  персидский

персидский  Польский

Польский  португальский

португальский  панджаби

панджаби  румынский

румынский  Русский

Русский  Самоанец

Самоанец  Шотландский гэльский

Шотландский гэльский  сербский

сербский  Английский

Английский  Шона

Шона  Синдхи

Синдхи  сингальский

сингальский  словацкий

словацкий  словенский

словенский  Сомали

Сомали  испанский

испанский  суданский

суданский  суахили

суахили  Шведский

Шведский  Тагальский

Тагальский  таджикский

таджикский  тамильский

тамильский  татарский

татарский  телугу

телугу  тайский

тайский  турецкий

турецкий  туркменский

туркменский  украинец

украинец  Урду

Урду  уйгурский

уйгурский  Узбекский

Узбекский  вьетнамский

вьетнамский  валлийский

валлийский  Помощь

Помощь  идиш

идиш  Йоруба

Йоруба  Зулу

Зулу