The float glass manufacturing process stands as a pinnacle of industrial innovation, revolutionizing the way glass has been produced for architectural and automotive purposes. Its significance in the modern world cannot be underestimated, as it provides a seamless means of producing high-quality, uniform glass sheets essential for various applications.

In the decades since its inception, the float glass method has transformed from a breakthrough in production technology to a standard for quality and efficiency. The process begins with the careful selection and precise mixing of raw materials, including silica sand, soda ash, and limestone. These inputs are critical, not only for the consistency of the final product but also for ensuring durability and clarity.

Once mixed, the raw batch is melted in a high-temperature furnace, reaching temperatures exceeding 1700 degrees Celsius. This molten glass is then carefully channeled onto a pool of molten tin. The choice of tin as a substrate is strategic; tin remains in a liquid state at lower temperatures and has a high atomic number, providing a perfectly flat surface upon which the molten glass can spread without reacting with it or causing imperfections.

As the glass flows over the tin bath, it naturally forms a flat, even surface due to the balance of gravity and the surface tension of the tin, resulting in sheets that are uniform in thickness and free from distortions. The atmosphere above the tin bath is tightly controlled, often with a protective gas layer, to ensure that no oxidation or other contaminants disturb the pristine quality of the glass.

Subsequently,

the glass is gradually cooled in a process known as annealing. This stage occurs in a controlled environment called a lehr, where the temperature is systematically reduced, allowing internal stresses to be relieved. Proper annealing is essential for the glass to maintain its structural integrity and resist breaking after installation.

float glass manufacturing process

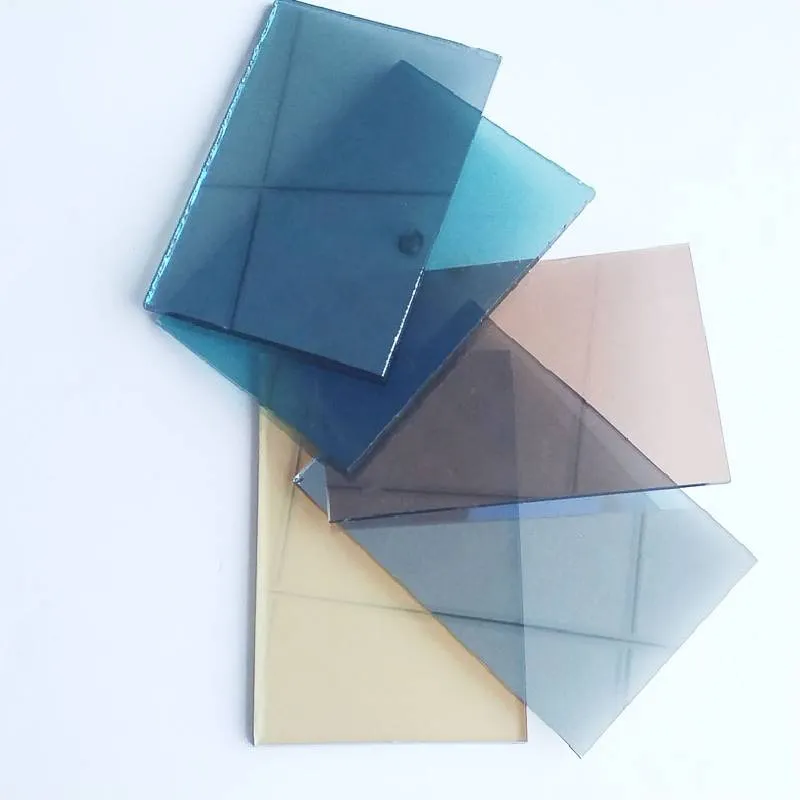

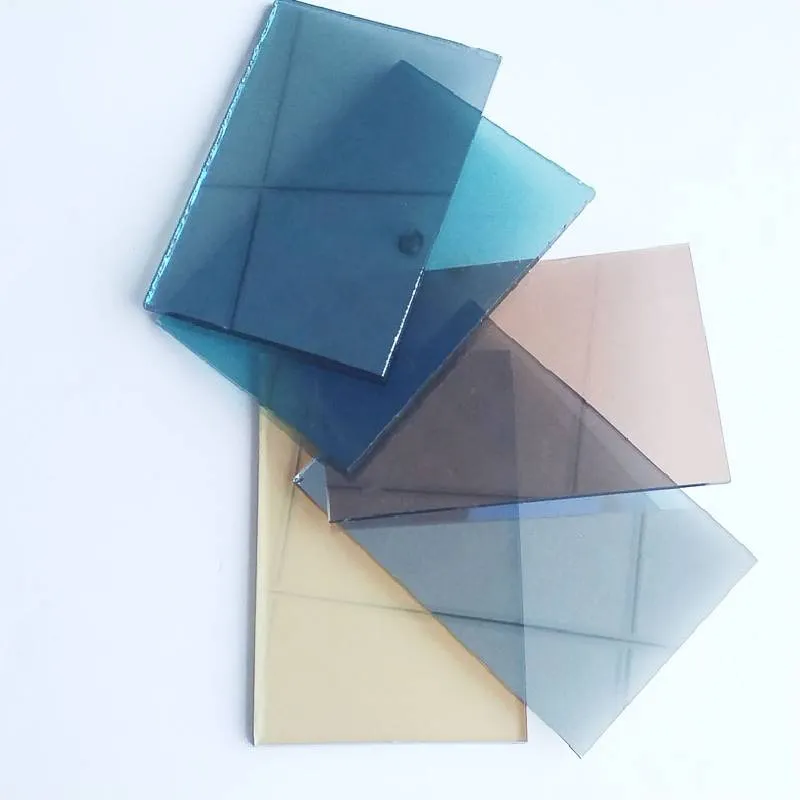

The final product is inspected rigorously to adhere to industry standards and client specifications. Advanced optical systems and human inspectors ensure no imperfections, such as bubbles or inclusions, remain on the glass surface. The precision of the float glass manufacturing process also means that additional treatments, such as coatings for energy efficiency or coloration for aesthetic purposes, can be applied with minimal additional processing.

A testament to its engineering excellence, the float glass process isn't merely about producing glass; it involves a comprehensive understanding of material science, chemical engineering, and industrial design. Companies engaged in float glass production invest heavily in research and development to maintain high quality, optimize efficiency, and minimize environmental impact by recycling excess materials and reducing energy consumption.

In today's competitive marketplace, where sustainability and performance are key, the float glass manufacturing process stands as a robust example of balancing high output with environmental responsibility. Its efficiency and cost-effectiveness make it the backbone of the global glass industry, shaping the skylines of cities and advancing technological innovations in automotives.

Among the challenges faced in the ongoing evolution of the float glass manufacturing process are the implementation of newer automation technologies and artificial intelligence for quality control and the development of glass types better suited to modern demands, including smart glass technologies and enhanced energy-saving glass.

In conclusion, the float glass manufacturing process encapsulates a sophisticated blend of scientific principles and industrial practices. Its evolution remains crucial to numerous sectors, providing insights into how traditional manufacturing processes can adapt to contemporary challenges without compromising on quality or efficiency. As industries continue to demand better and more efficient glass solutions, the float glass process is set to remain at the forefront of innovation and reliability.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu